Why Schweiss Powerful “One-Piece”

HYDRAULIC DOORS?

- The best hydraulic & electrical system on the market

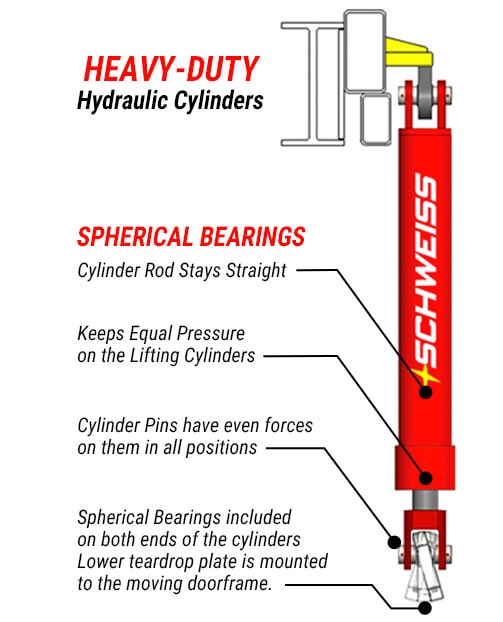

- Faster, Bigger Cylinders... with Spherical Bearings

- Provides a canopy when open

- All-steel framework... Stronger... Better... Safer

- Steel cross members on Schweiss hydraulic doors

- Easy-to-install...

- Comes complete with its own strong subframe

- Clean Looking Doorframe... All-Steel Frame...

- Easy-to-Insulate... Easy to Line Inside Doorframe

- The hydraulic door you see is fully insulated and lined

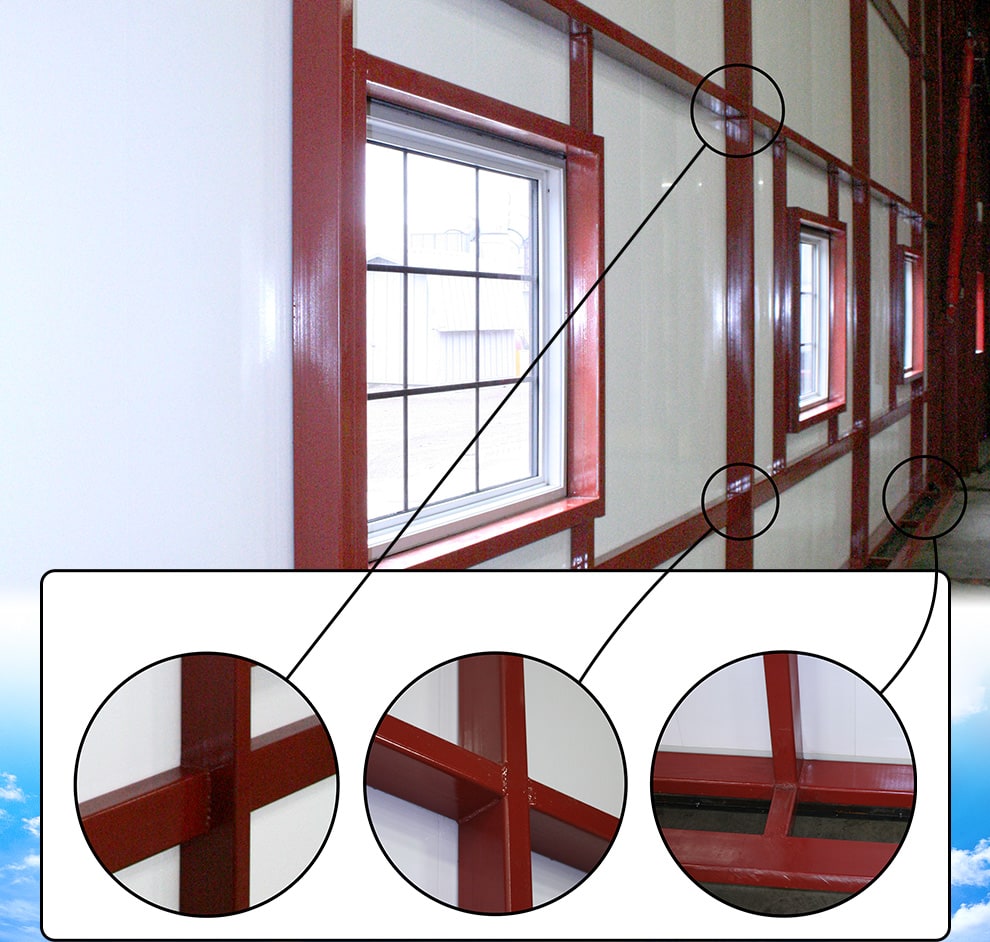

- Easy-to-Install Windows... any size, any location

- All-steel window frames are welded at the factory

- Welded Cross Members... A Strong Connection

- Strong steel doorframe on Schweiss Doors...

- Internal Truss... Clean apperance to the building

- External Truss available

ALL-STEEL DOORFRAMES ARE BETTER!

Schweiss Uses

All-Steel Members

Internal Truss on this door External Truss is available

ALL-STEEL

STRONG CONNECTIONS

CLEAN DESIGN

- Canopy When Open

- Lights Installed On The Door

FARM DOORS

Schweiss now offers both

RED and GREEN Hydraulic pump

and Cylinder Paint Colors

THE BEST JUST GOT BETTER!

Schweiss has the Best Hydraulic Pump and Door on the market

SCHWEISS DOORS HAS TAKEN EXTREME PRIDE IN INTRODUCING ITS NEW POWERFUL RED AND GREEN POWER PUMPS TO THE WORLD.

From the minute you press the control button on your handy remote control, you'll be amazed at how this door functions. It's everything you want it to be and more.

The unit has all the bells and whistles and comes with single or 3-phase electrical components. Easy to read psi pressure gauge, service filter and fluid temp gauges let you know that the door is always working properly and at full capacity. Everything is in one compact hydraulic pump unit powered by 2, 3, 5 or 10 horsepower motors to safely lift even the smallest or heaviest doors and seal them tightly.

The Schweiss Safety Advantage allows the door to lock up and down or safely lower or raise your door in case of electrical failure. Each unit comes with a standard tractor hydraulic hookup; lower the door at any time; very handy for agricultural or industrial applications. Specially designed built-in manual override allows the operator to lower the door in case of a power outage. Battery backup features that use a DC battery or drill to operate the door in either direction in case of an emergency, giving you a superior backup system for your door and peace of mind.

A WELL THOUGHT-OUT DESIGN... RED POWER PUMP... ONE OF A KIND

They're powerful... We're talking THE most Efficient Pumps with standard motors designed ready to lift any size door, at any time, all the time!

- They're Reliable... Safe, Carefully Designed Hydraulic Pumps that operate at 95% efficiency.

- They're Quiet... This amazingly smooth, quietly operating pump system.

MOUNTING STYLES:

Over the years Schweiss factory engineers rolled together customer comments, combined with high-tech design knowledge and experience to come out with perfection in a compact pump unit ready to be mounted anywhere you want it.

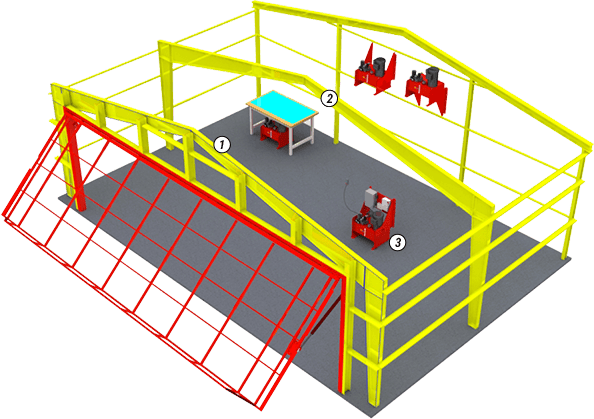

• Wall Mount • Floor Mount • Under the Bench • Back Room

MULTIPLE PUMP MOUNTING OPTIONS

- Under Workbench - Hydraulic power unit can be placed under a workbench or anywhere in the room.

- Wall Mount: Up or Down - mount anywhere away from the door opening or even in another room.

- Stand Alone Unit - Complete stand-alone hydraulic unit can be placed anywhere in the building.

- Up/Down/Stop Switch - Mounted near the door opening.

- Electrical Control Panel - Can be mounted independently from the hydraulic pump.

Hydraulic Doors by Schweiss

Schweiss hydraulic doors are custom made

to fit any size opening for your building.

Each door is built to fit your clear opening

without using up existing headroom.

There is no such thing as an odd size

door or a job too small. You dream it,

and we make your dreams come true.

Hydraulic Doors

Schweiss Doors is proud of its new

hydraulic doors that swing outward.

Already a leader in the bifold door industry,

Schweiss Doors also now offers a better

hydraulic door. The door design requires zero

headroom, comes pre-hung, is watertight, easy to

install, easy to operate with the push of a button, easy

to insulate and swings out to povide a canopy when the

door is in the open position.

Simple Unique Design

Powered by a powerful hydraulic pump, two heavy duty cylinders activate the hydraulic doorframe. Hinges across the top of the doorframe allow it to swing out and away from the building to the full open position. The hydraulic pump can be located away from the door opening to keep a good luck.

ONLY FROM![]()

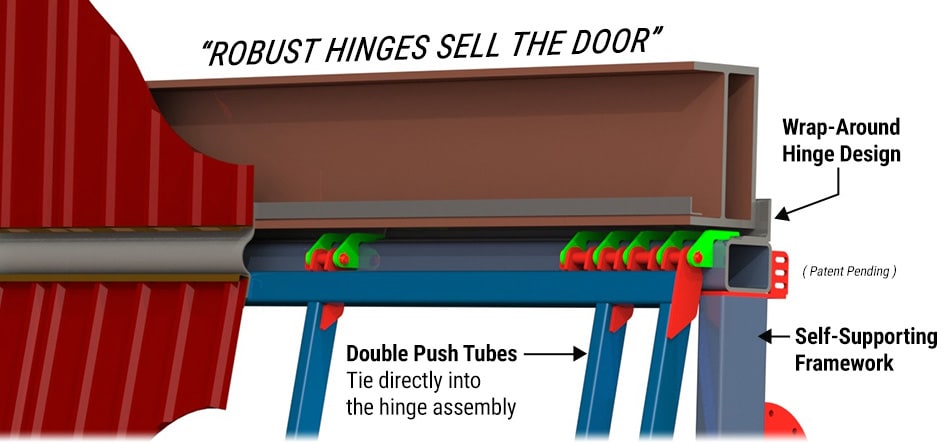

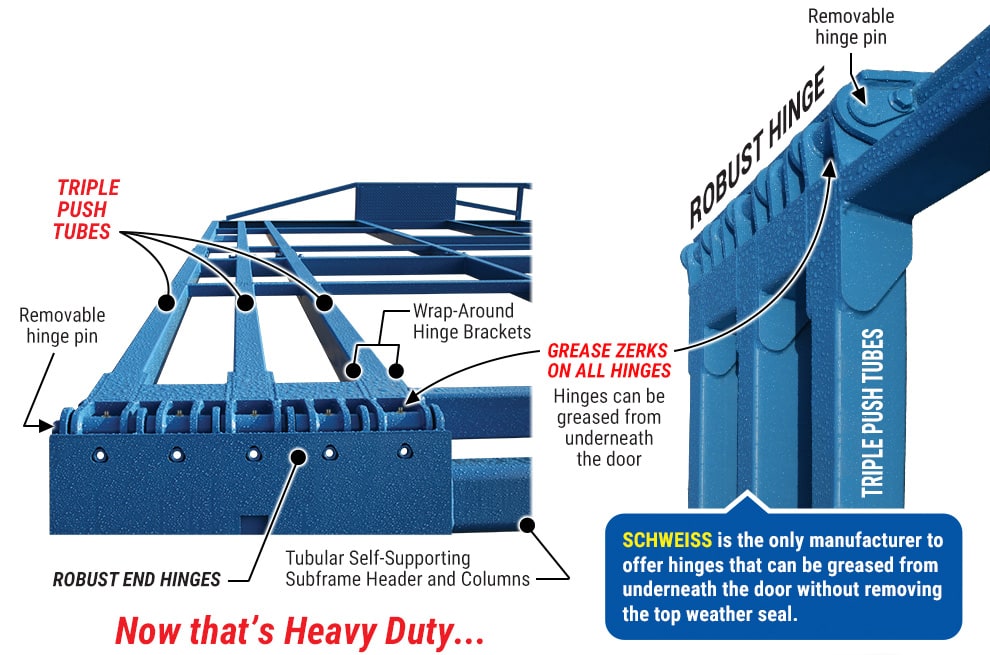

New Hinge Design...

"Our New Wrap-Around Hinge Design Sets The New Standard For Hydraulic Doors"

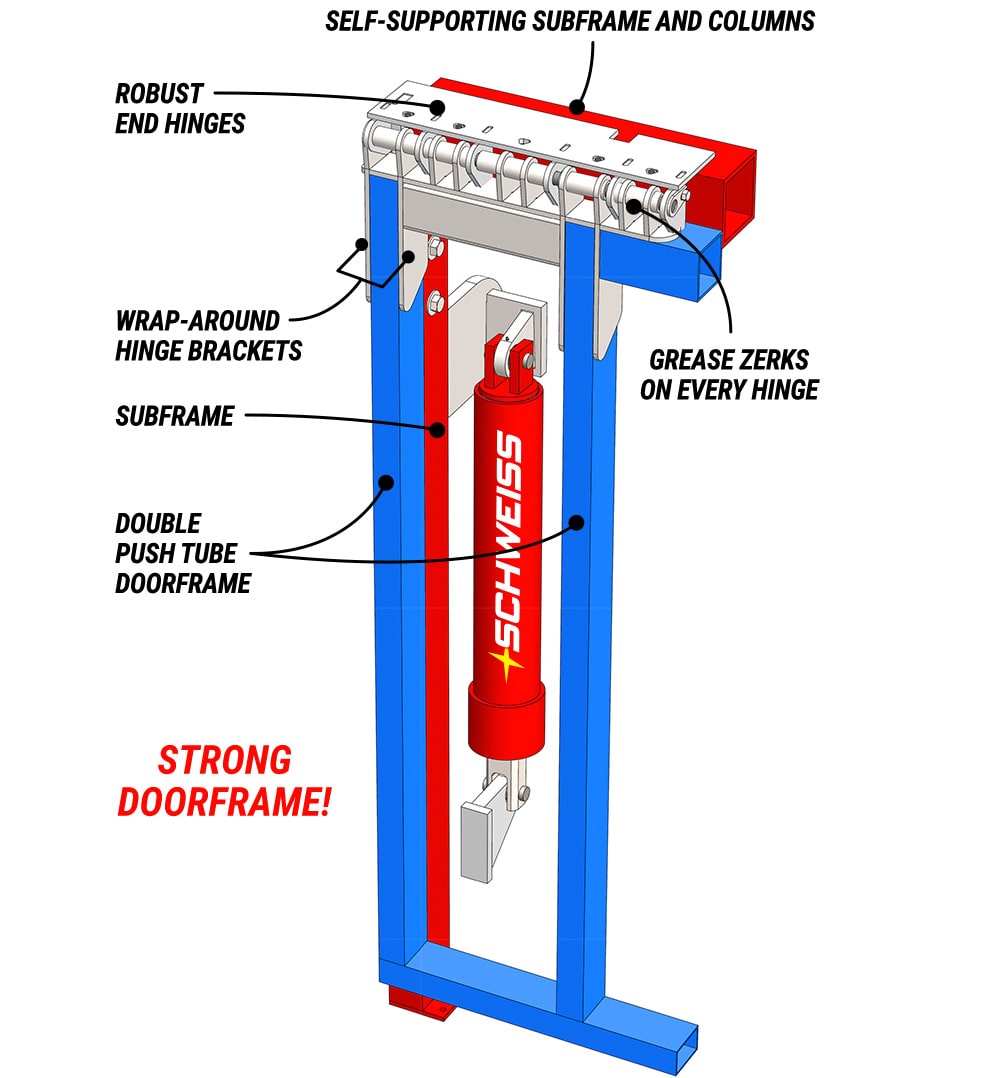

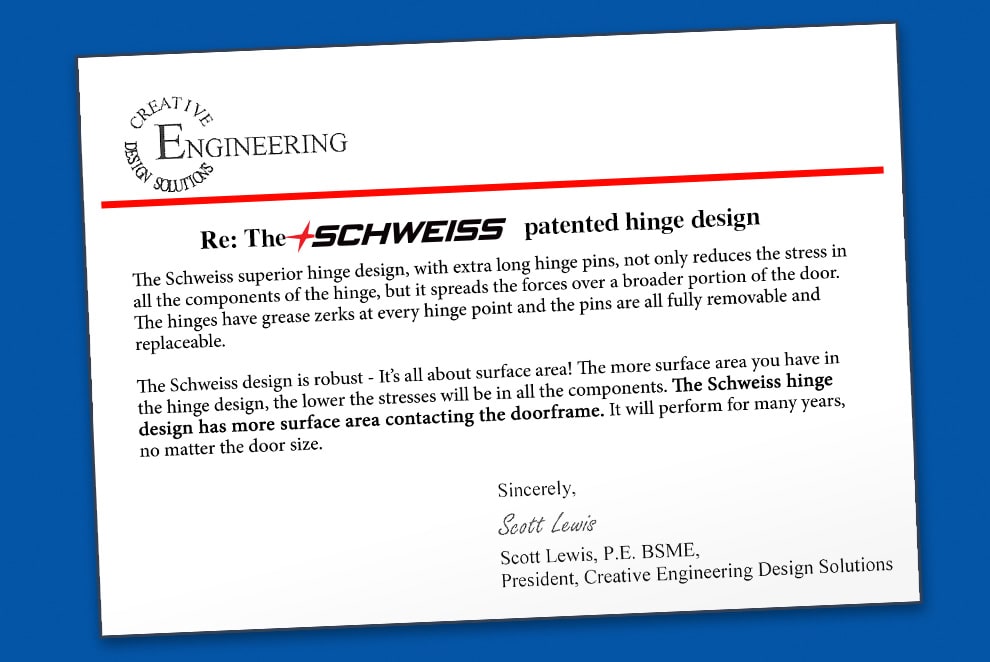

Schweiss doorframes are designed with double push tubes that are tied directly into the wrap-around hinges that connect both vertical push tubes directly to the header tube. The advantage of double push tubes is that forces of hydraulic cylinders are evenly distributed to the doorframe and the wrap-around hinges.

"There have been hydraulic doors with hinge welds that failed, literally tearing off the doorframe and destroying the door," Schweiss says. "Our design team provided a durable wrap-around hinge with grease zerks that are accessible without removing the top rubber seal."

Its Own Self-Supporting Subframe!

Schweiss engineered a new robust hinge design that distributes the door loads evenly across the self-supporting subframe, greatly reducing stress on the building structure.

The Hinges Sell The Schweiss Door

The Schweiss robust hinges are designed to withstand the door weights and hydraulic forces of the cylinders as the door opens.

Your door is only as good as its hinges! Take one look at the Schweiss hinges and you will clearly see the workmanship, strength and functionality of each hinge. The Schweiss hinges are big... strong... heavy-duty.

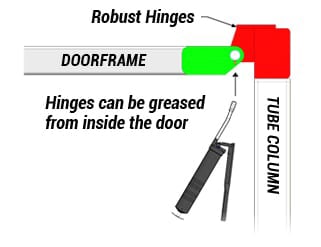

Grease Zerks

- • Schweiss hinges can be easily greased for longer hinge life.

- • SCHWEISS is the only manufacturer to offer hinges that can

be greased from underneath the door without removing the

top weather seal.

Removable Hinge Pins...

- • It's important to have removable hinge pins...

- • Hinge pins are not welded in solid on a Schweiss door.

- • Designed for easy maintenance.

- • All hinge pins are removable.

The hinge makes the door...

The weight of the door and hydraulic forces exert loads on the hinge while the door is operating.

So it had better be STRONG!

The unique hinge design incorporates heavy hinge plates that wrap around each vertical push tube for added rigidity. Without this wrap-around design, the doorframe members can be overstressed and begin to tear apart from door weight and hydraulic forces over time. This won't happen with a Schweiss Door!

Hydraulic doors operate with one set of top hinges. These hinges need to be strong enough to support the door weight and the hydraulic cylinder forces when opening; unlike a bifold door that shares the load between the top hinges and the center hinges.

What Door Customers Are Saying...

- “The hinges sold me.”

- “The Schweiss team hit a home run by putting grease zerks in their hinges”

- “Now that's a Serious Hinge, You guys have it figured out!”

- “Oh my, nothing comes close to it. Professionally done!”

- “Nothing on the market will even come close to the Schweiss hinge design.”

Strongest Hinges on the Market!

Strongest Doorframe on the Market!

Schweiss Hinge Advantage...Standard On Every Door!

While other doors may appear to be the same on the surface, there is really...No Comparison!

- Greasable hinges on each and every hydraulic door

- Ability to grease the top hinges without removing the top rubber seal

Customers Welcome Greasable Hinges

HINGE SURFACE AREA

Hinge surface area is critical on large moving doors. Over the years, we all have heard of hinge failures on others doors. Large hydraulic cylinders are putting extreme forces on each of the outer hinges of the doorframe. Schweiss has designed and patented a robust hinge with more surface area to evenly distribute the loads of a moving one-piece doorframe. Look at the hinge surface area. The stresses on the very outer hinges are immense. With that being said, take one look at the patented Schweiss hinges and you'll clearly see the workmanship, strength and functionality of each hinge.

GREASABLE HINGES

It's very important to be able to grease the door hinges with a heavy viscosity grease. When grease is used on the hinges of a large moving door it avoids unnecessary wear and adds longer life to the hinge and the doors operation. It's a common manufacturing practice to use grease on the critical wear points and load points to avoid unnecessary wear just like in the industrial equipment world with implements such as payloaders, skidloaders and other industrial equipment that are being operated around the clock.

The new hinge design with grease points on every hinge segment enables owners - whether they be private individuals or commercial customers - to periodically grease their hinges from inside the doorframe without having to go through the cumbersome process of first removing the top rubber weather seal.

Advantages of Grease

Using grease on the hinges is a better method of lubrication.

Using grease on the hinges is the industry standard.

Using grease on the hinges makes for a quiet door.

Using grease on the hinges makes for a smoother operating door.

Using grease on the hinges extends hinge life

Greasable hinges last forever.

Look at the Schweiss hinge, it has more lubricated surface area to give you longer life

Others rely on bushing FOR LUBRICATION

Doors move and flex as they open and close. The forces on each hinge vary during operation.

Not all bushings wear evenly.

Bushing wear thin over time.

Worn bushings offer less lubrication.

Less hinge surface area to distribute the door loads across the door header tube.

No way to inspect the bushings when the hinge pins are welded in - Not removeable.

Almost impossible to replace the bushings when the hinges pins are welded in solid.

Hinges That Are Easy To Grease

. . . Only From

Strong, Beautiful, Functional

- Double push tubes for added strength

- Self-supporting subframe on every door

Fast Moving... Easy To Install... Gain Headroom...Large Cylinders Open Large Door

Doors Include

Spherical Bearings

Doors Include

Spherical Bearings

“No one else in the industry offers this unique feature”

Only available on Schweiss Doors...

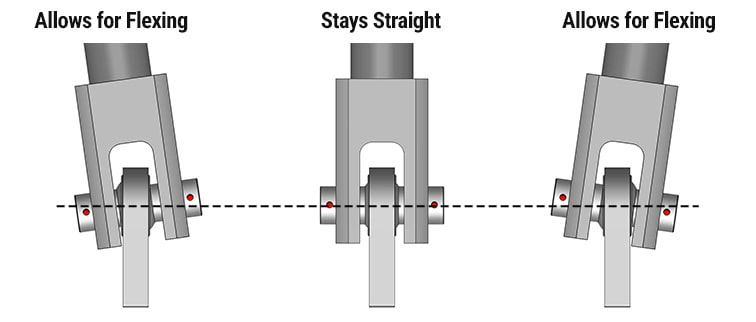

Doors Are Always Moving and Flexing

Spherical bearings reduce stress and wear on the cylinders, cylinders pins and clevishes during operation.

Hydraulic doors are large in size and just like an airplane wing, the doorframe flexes during operation. The hydraulic cylinders on each side of the doorway are connected to the doorframe and the building using spherical bearings. The spherical bearings accommodate the flexibility of the doorframe while at the same time allowing the cylinders to raise and lower the door without binding on the hydraulic cylinder pins and brackets. Spherical Bearings on both ends of the cylinder allow the cylinders to stay straight through the full range of motion.

Strong Words From Our Customer

“Soon as I saw and understood the spherical bearings design, it was a no brainer. I was immediately SOLD on the Schweiss Hydraulic Door!”

RED POWER Hydraulic Pump

HEAVY-DUTY Hydraulic Cylinders

LEARN MORE ABOUT DOOR MANUFACTURING . . .

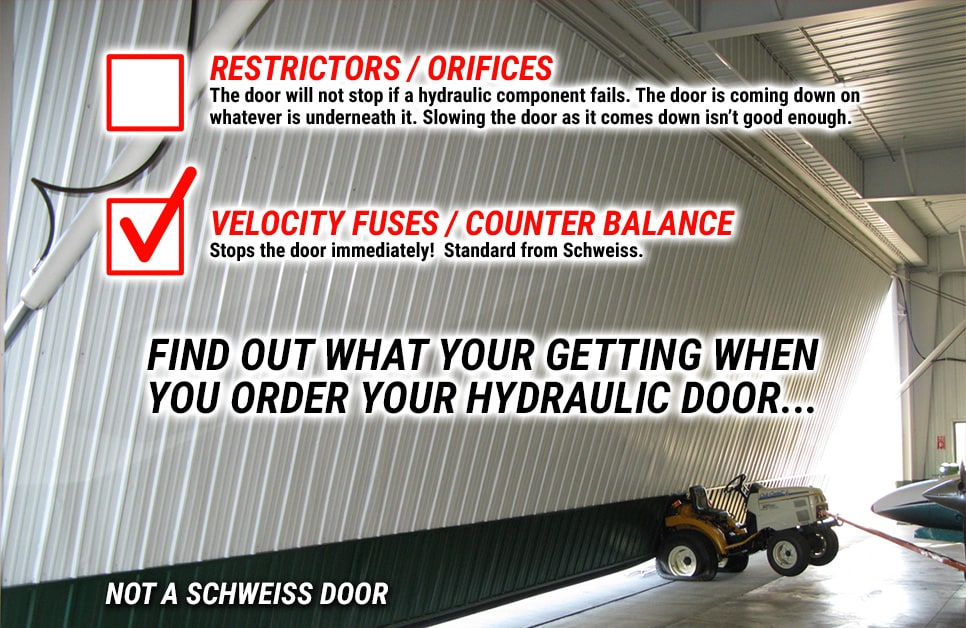

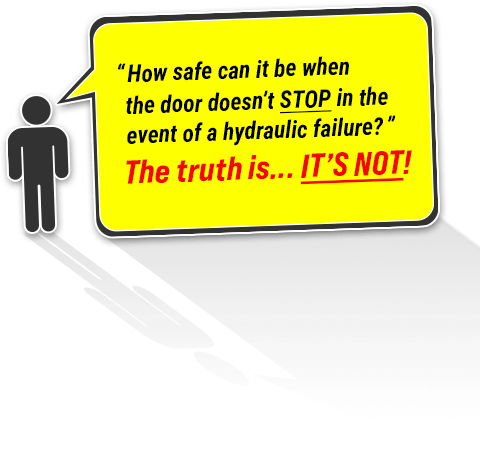

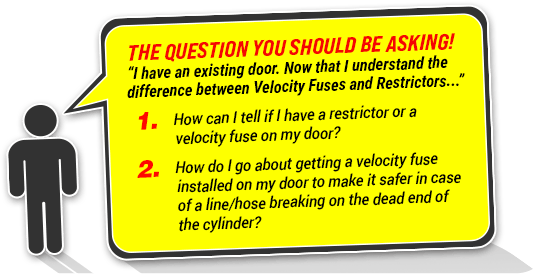

If There Is A Failure Of A Hydraulic Component, The Door Needs To Stop Immediately!

Stopping the door completely in the event of a hydraulic component failure can be accomplished with a VELOCITY FUSE or a COUNTER BALANCE. The Schweiss Way

Restrictors or Orifices... Have been used by some manufacturers as a safety feature.

WARNING

When others are using restrictors/orifices in the

dead end of the cylinder as a safety device...

- They may be setting you up for slow

motion disaster, Your worst nightmare!

Worst Case Scenario...

To have a door come down on a million dollar plane

or even worse than that, have the door come down

on people and put lives at risk!

Be careful... when phrases like these are being used to explain what happens in the event of a hydraulic hose/line failure using restrictors.

- “Gently coming all the way down...”

- “Controlled rate of descent...”

- “Coasting down...”

- “Preventing the door from slamming down...”

Some Have Said:

“In the event of a hose or line breaking, it will not stop the door from falling.

It takes 7 seconds for a door to come down when a hose / line breaks.”

Fact Is... That's Not A Lot of Time!

The door is coming down with no safety built-in to stop the door. Better clear the area!

When manufacturers use Restrictors on their cylinders...

- No safety built-in.

- Restrictors are not load holding.

- No way of stopping the door from coming down.

- Slow motion distaster... Your worst nightmare!

- The door won't stop if a hose/line fails (on the dead end).

- Door will come down if there's a failure, no matter what.

- The door is coming down on whatever is underneath it.

- Slowing the door as it comes down isn't good enough.

Did You Know?

If the manufacturer uses restrictors on the dead end of the cylinders, neither the restrictors nor the photo eyes will stop the door. You can't rely on the photo eyes to stop the door if a hose/line breaks on the dead end of the cylinder.

The Door Is Coming Down...

Restrictors Are Not A Safety Device!

Find out what safety devices you're getting on the hydraulic cylinders when you order your hydraulic door.

Call Schweiss

Ask yourself...“Do I know what I'm getting?”

“Is Safety Important To Me?”

Doors Does More Doors... and Better!

Doors Does More Doors... and Better!

A Name You Can Trust Manufacturing Doors Since 1980

Did You Know...Some Folks Are Having Issues With Their Hydraulic Door Supplier

Such As:

- Problems getting their door.

- Problems getting their door components.

- Door was received, less the major components, hydraulic pumps and/or cylinders.

- Paid the door deposit required to start the order and have been waiting and waiting.

- Stopped taking calls.

Do Your Own Research and Learn More!

- Do they have a factory?

- Do they even manufacture their own doors?

- Do they seem too eager to take your deposit?

Some telltale signs - Examples

- If you call and there's no salesperson available to talk to you.

- If you call in and you are told “I'll have someone call you back.”

- If you call in and you only get voicemail.

- If there is a slow response to emails ... or no response at all.

Schweiss Wants To Earn Your Business!

- Need a door quote?... Get one immediately!

- Have additional door questions that need to be answered?... just call in!

- Delivery time estimated at 4-6 weeks!