Tilt-Up Doors

“New” Patented Schweiss Tilt-Up Doors...

- A Secure Linkage System

Keeps The Door Stable And Precise As It Operates - No Tracks or Cam Rollers

That Shift, Bind, Or Create Safety Hazards - Streamlined Design

With Fewer Moving Parts. - Short Lead Times...!

Starting To Open

Opening

The Result?

A clean, elegant, patented design engineered to perform in demanding environments.

- Hydraulic power for smooth, controlled operation.

- Engineered to perform. Designed to lead.

Schweiss Gives You Options...

HydraulicvsTilt-Up Doors

Customers Say Tilt-Up Doors Are Difficult To Keep Sealed!

While other doors may appear to be the same on

the surface, there is really... “No comparison”

Here's why . . .

Typical characteristics of a tilt-up door...

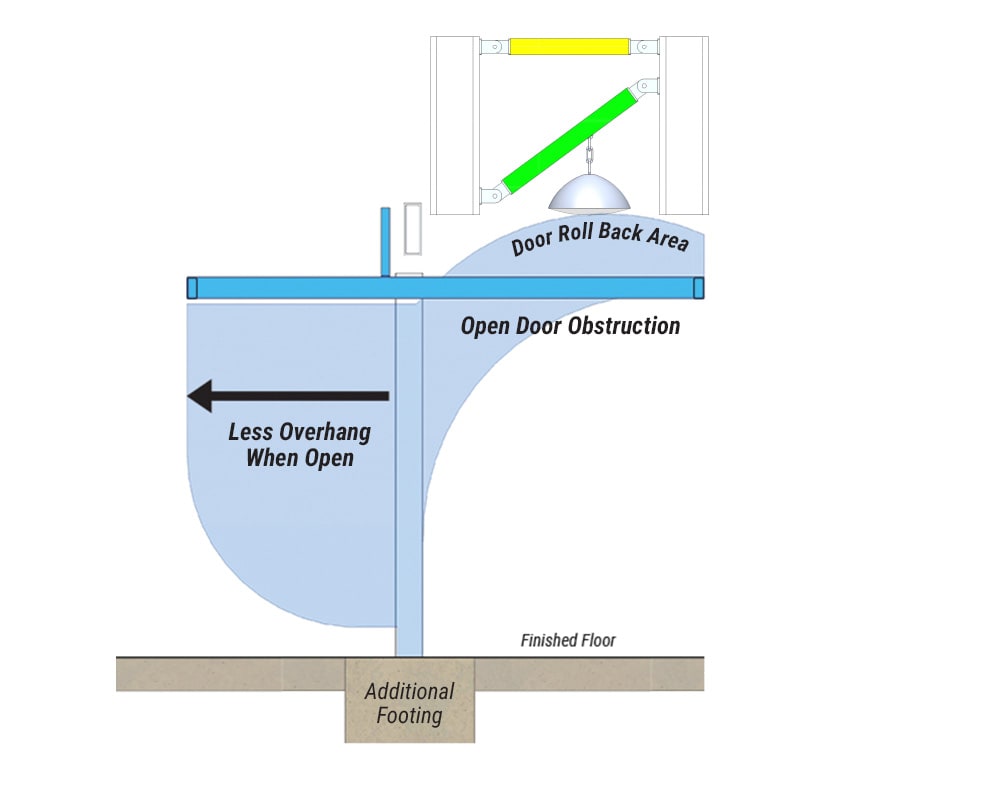

On tilt-up doors, one-third of the doorframe slides

back into the building when open, similar to old style

garage doors! The doors cylinders are attach to the

side of the doorframe. The door is guided by a

set of rollers that go along for the ride, guiding/

balancing the doorframe back into the building

which results in the loss of valuable headroom!

Remember the Old Style Garage Doors?

Some manufacturers have created an alternative

by building a hydraulic door similar to the old style

garage doors without hinges. The door, when open,

rolls back into the building structure, resulting in loss

of valuable headroom, and it has moving parts, push slides,

cam-rollers, and cam-tracks. The door, when open, teeters on

two pivot pins and the cam-rollers ride in a track that protrudes

back into your building.

Most customers prefer having a hangar door that doesn't intrude into the opening nor the interior, or put its contents at risk in any way.

Two Pins Support the Door When Open.

The door also has (2) pins that support the door when it is in the open position as well as when

it is closed. These two pins are seeing most, if not all of the load. These two pins are all that

would be taking the load during a wind event when the door is closed.

TILT-UP DOORS ARE ALMOST

IMPOSSIBLE

TO SEAL PROPERLY!

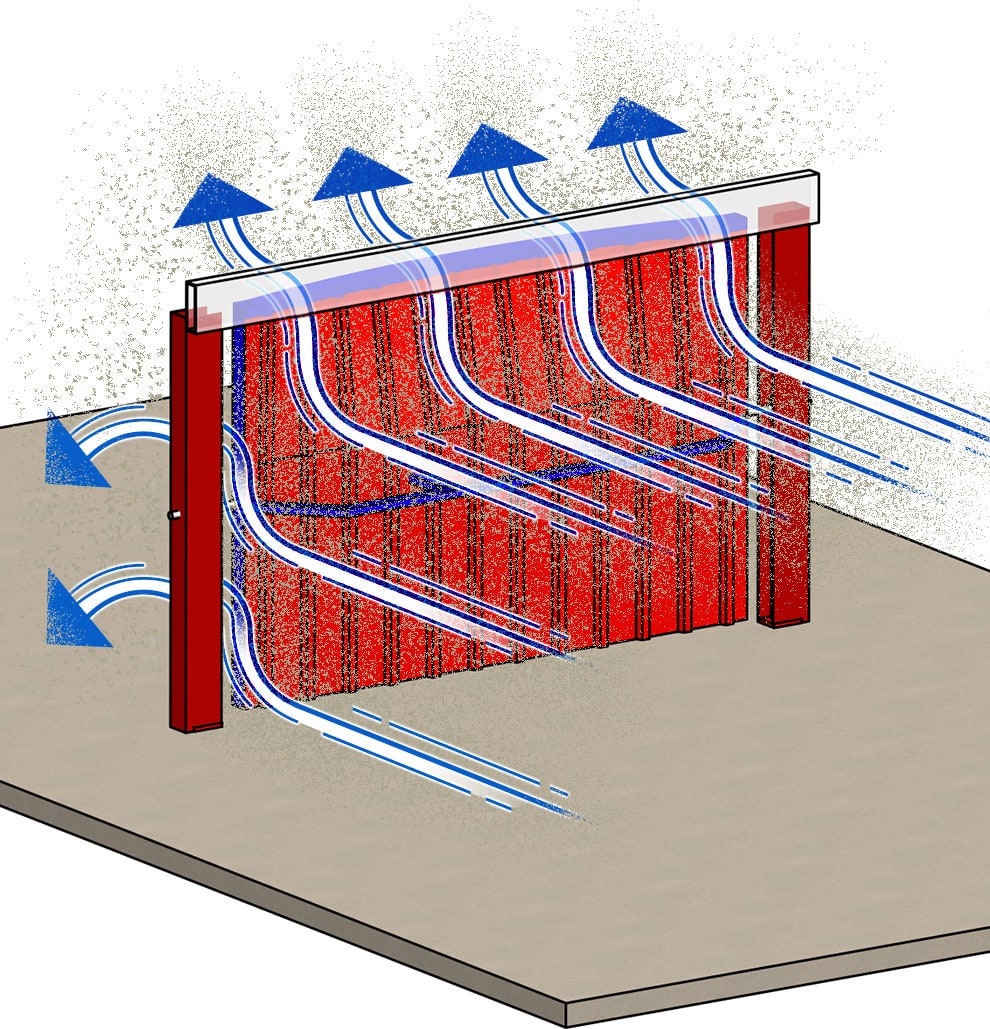

Tilt-Up Doors Can Experience Sealing Issues

Tilt up doors can experience sealing issues due to weather stripping damage, door misalignment, or problems

with the bottom seal. These issues can lead to air and moisture infiltration.

These Issues Can Lead To

Air And Moisture Infiltration Causing:

- Lose Heat In The Winter!

- Lose Cool Air In The Summer!

- Allow Dust Into The Building!

- Allow Rain or Snow Into The Building!

The Top Of The Doorframe Doesn't Seal Tight Against The Header And The Sides Of the Door Has Gaps!

By Design... Tilt-Up Doors Do Not Have Top Hinges To Secure The Doorframe to The Buildling Header

- Offer less doorframe stability

- Harder to seal

- Water can leak in

- Lets in dirt and debris

- Snow can blow in

By Design... Tilt-Up Doors Are Difficult To Seal

Tilt-up doors make it difficult to seal out the elements. Elements such as water, dirt, wind and snow can blow in and capture the heat in the cold months and air conditioniong in the hot months

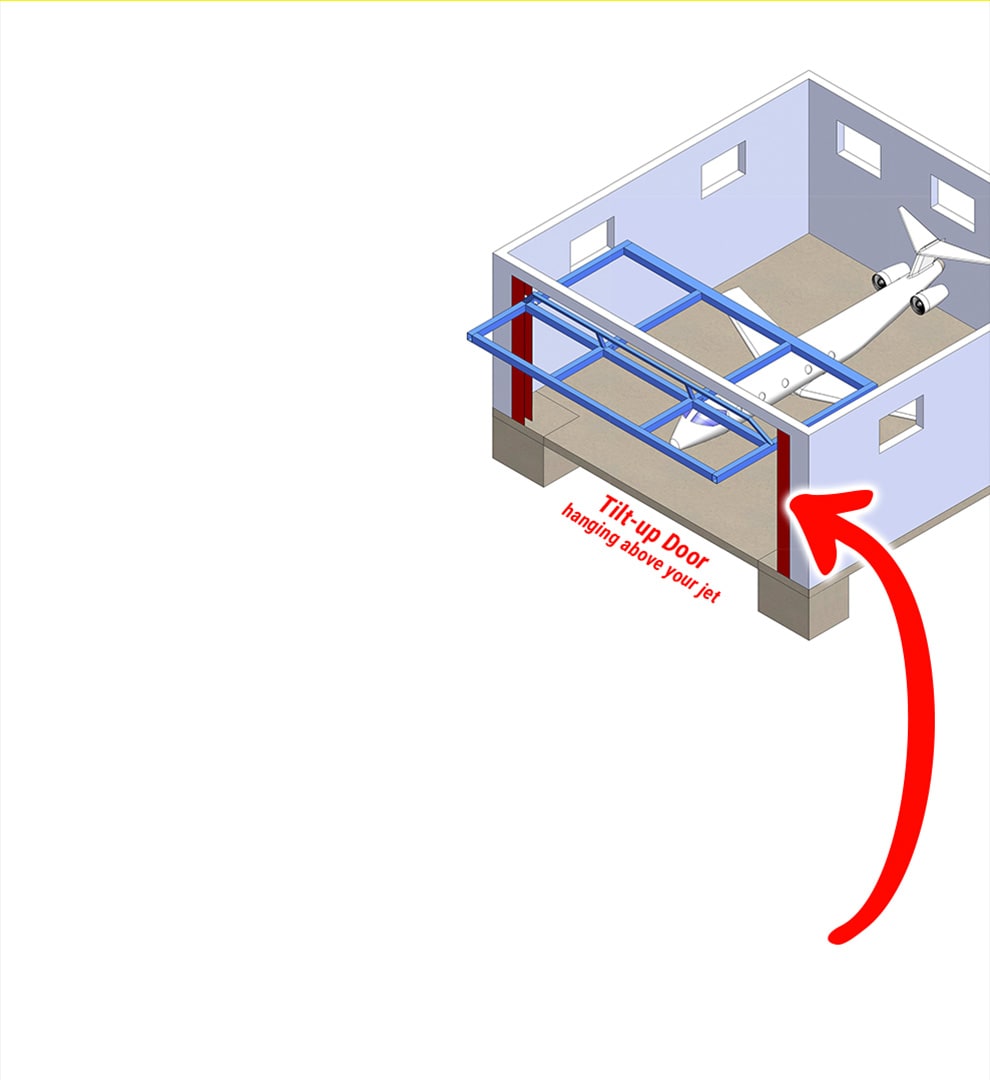

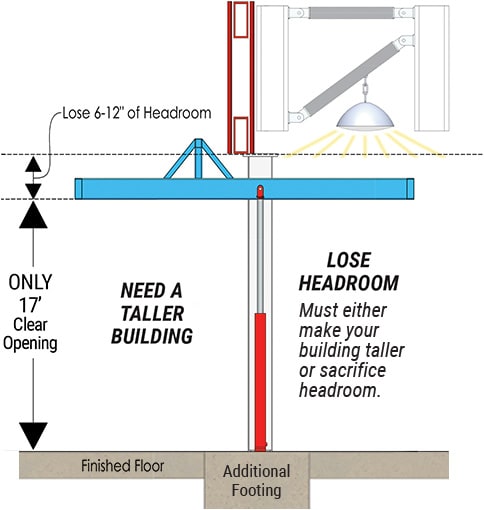

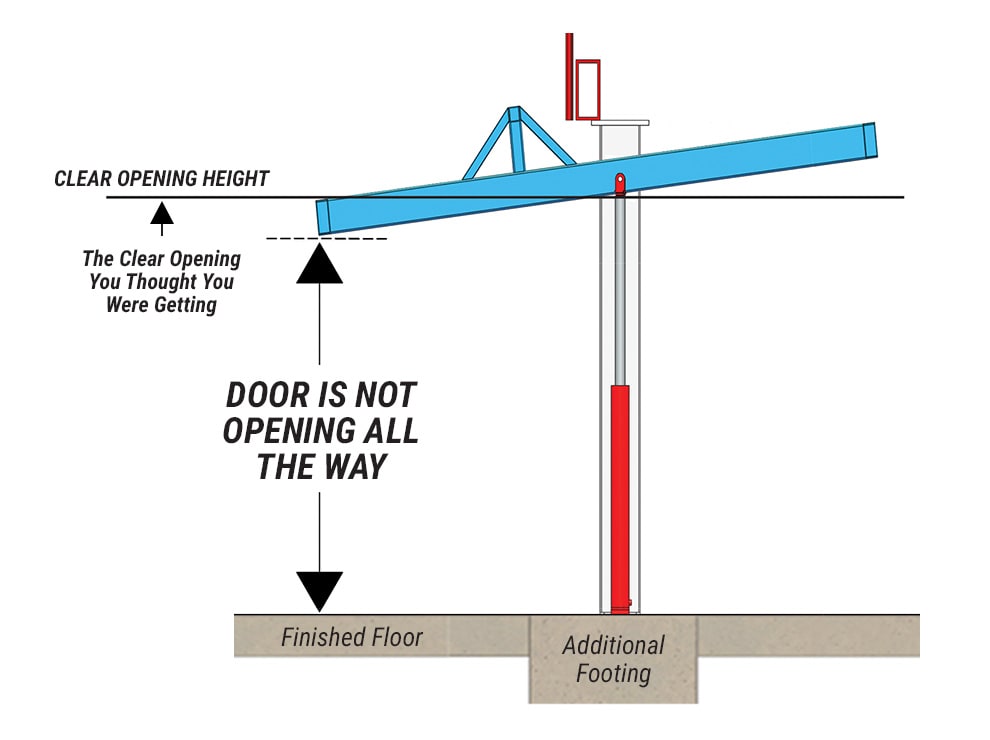

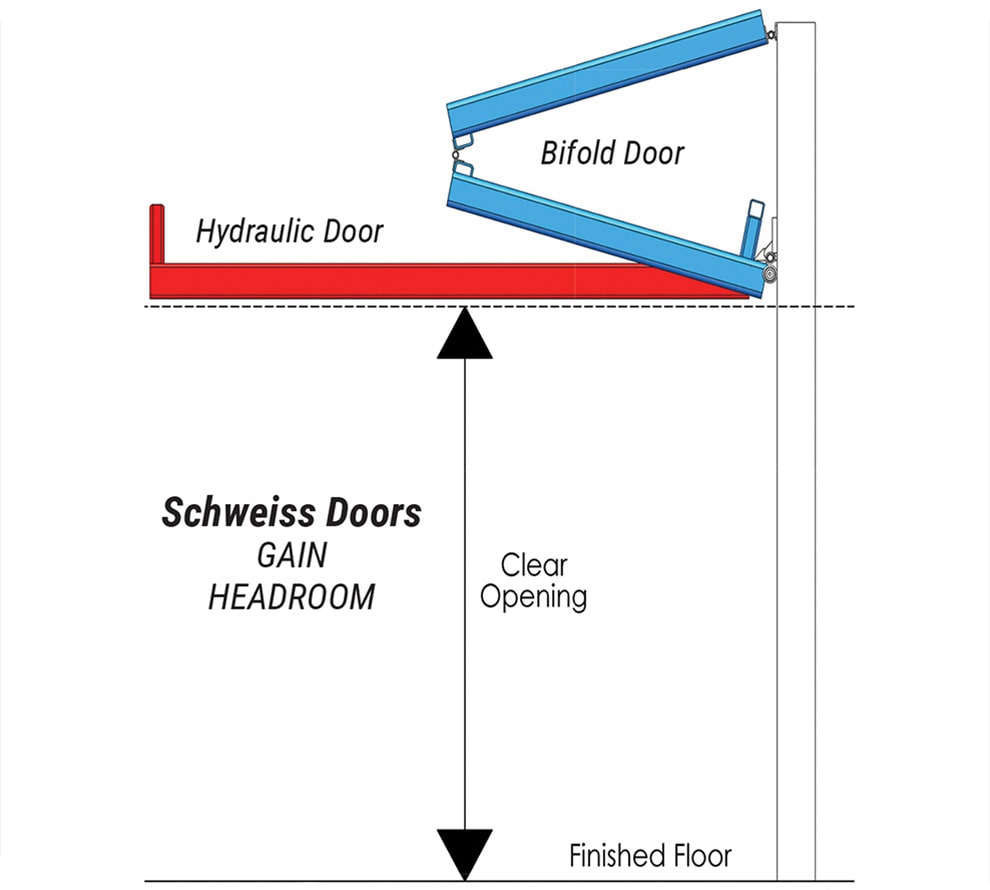

Lose Headroom With Tilt-Up Doors

Tilt-up Doors open to the inside of the structure. When the tilt-up door is in the fully open position, one third of the door slides back into the building similar to the old style garage doors — losing valuable headroom! Tilt-up doors obstruct valuable inside space when open and utilize a cam mechanism that travels within a framework, reducing headroom space inside the building structure. This costs you valuable headroom and space you paid for, in addition to blocking interior lighting!

Tilt-Up Doors - Lose Headroom

No Hinges To Secure The Door

Tilt-Up Door

Lose Headroom

Almost impossible to create

a weather tight seal.

Customer Says:

“The headroom loss from a tilt-up door as compared

to a Hydraulic door type was a deal breaker for me.”

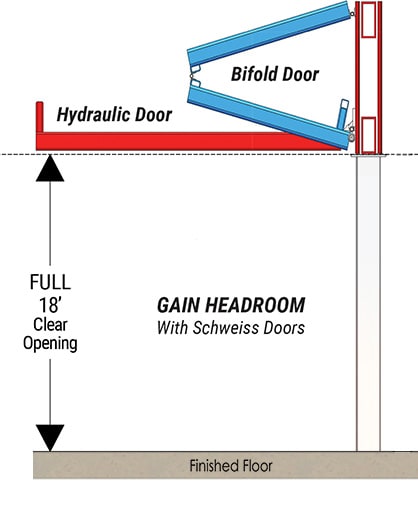

The Schweiss Advantage

Gain Headroom

Hinges Secure The Door

Hydraulic & Bifold

Door Advantage

Gain Headroom

Schweiss doors seal tight

Both doors have top hinges that secure the doorframe

Creates An Obstruction

Tilt-Up Doors roll back into the

building creating an obstruction

when in the open position

LESS SHADE WHEN OPEN

Hingeless doors do not provide as much shade and will cover your lights inside the building when door is open!

INSIDE BUILDING

Blocks inside lighting

Lose valuable inside space

Blocks cranes and hoists

Door hangs over vehicles, airplanes and equipment.

Verify Your Clear Opening

You Were Sold A Clear Opening.

But, does the door sag down when open

or not open all the way?

“Why am I not getting

the clear opening I was

promised?”

“Is there

something wrong?”

Message To Any Professional: Engineers, Mechanical Engineers, Building Manufacturers, And End Users Of The Door!

Any manufacturer that states that the door is “free-standing” and makes any of the following claims, you need to investigate further:

- Door doesn't require “any building supports.”

- Free-standing door with no building support.

- Door imposes no load onto the building.

- No massive header or horizontal bracing required.

- Only wind load is transferred to your building.

It is clear that when you study the reaction and load information...

that a tilt-up door exerts considerable loads on the building in all load cases.

- Check out the reactions at the base of the columns. Technically the loads at the base of the column are translated into the piers, not the building.

- Check out the loads at the top of the columns.

- Check out the vertical load component at the top of the columns.

- Check on the horizontal component of the load into or out of the building and the vertical component of the load.

- Check out all load cases. Take into account a portion of the dead load and a portion of the two wind loads used in any reporting.

- Check out the building reaction loads when the door is in the open position. Check out the reaction loads for the four load cases when the door is in the open position.

- Engineering analysis clearly demonstrates that wind conditions will result in a substantial amount of load being applied to the building by the door.

Despite the claims to the contrary, a tilt-up door DOES require building supports.

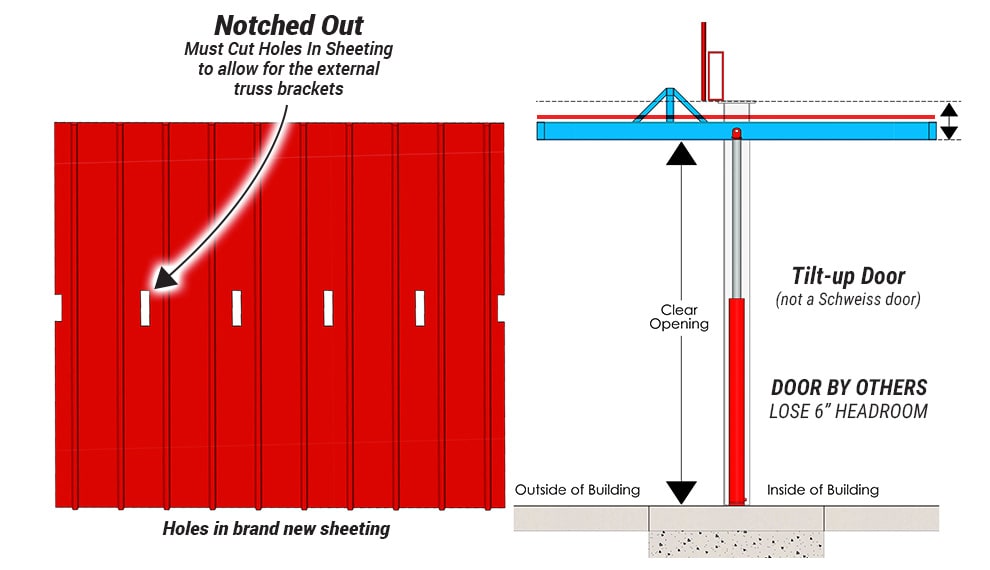

Why Would Anyone Take New Door Sheeting And Cut Holes In It?

Now...You Have To Seal The Holes?

- Will it keep Water out?

- How long will the seal last?

The holes in the sheeting need to be caulked around the center truss if you don't want water leaking in your building...

There's Got To Be A Better Design?

Tilt-Up Doors With An External Truss

Require Holes Cut In The Sheeting

An external doors truss mounts near the center of the doorframe. When cladding/sheeting the door, the sheeting is notched/cut out around the center truss brackets. They need to be caulked to keep moisture out!

Door In The Open Position

The doors lie flat in the open position. The nature of the door design does not allow water to flow off when open.

Gaps Around The Doorframe Need To Be Sealed!

The tilt-up doorframes are narrower than the clear opening

A hingeless doorframe sits in-between two columns. As the door opens it lifts up and floats inward simultaneously. The door requires a gap on each side with at least enough clearance for the doorframe to tilt back into the building as it opens! The gap on each side needs to be sealed! The doors are typically 1.5" to 3" narrower on each side of the framed opening!

The Gap Issues

- By design, the top of the tilt-up doorframe rotates into the

building while the bottom of the door swings out. - The doorframe does not overlap the door side columns which leaves a gap.

- The gap needs to be sealed to keep the weather and dust out.

- The design of the tilt-up doors make it difficult to maintain a proper

seal between the doorframe and door column. - If the size of the gap changes, it would make it more difficult to keep

the door sealed. - The tilt-up doors require constant maintenance to ensure the door

remains sealed properly.

The door doesn't seal well, making it harder to heat or

cool your building throughout the year, costing more!

The Water Test

“Water can leak through the sides

and top of the door”

“Water stays on the outside of the door”

The Wind Test

“Wind, dust, and snow can blow through the top and sides of the door”

“Nice, tight seal prevents wind, dust and snow from blowing into the building”

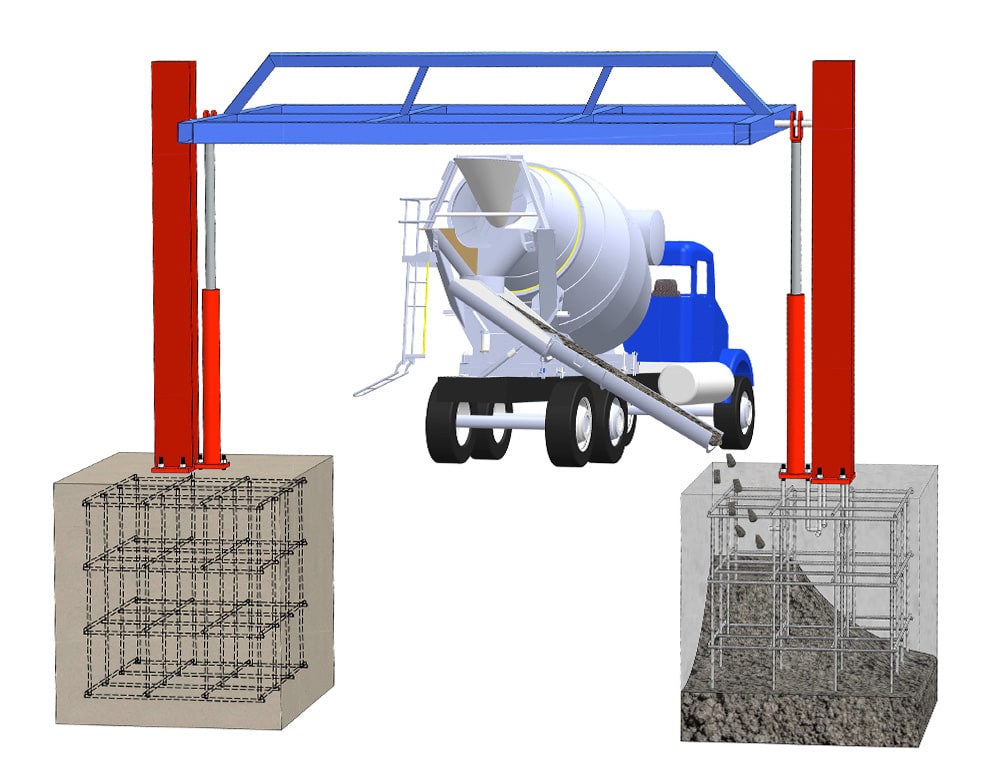

Special Footings Required

Customer must factor in what the additional footing cost will be adding to the cost of the door.

Special Footings

Tilt-Up Doors That Are Free Standing

Tilt-up doors require special footings - Hidden expense...

Additional footings and Anchor Bolts must support the door in all positions.

Frost Heaves and Snow Under the Doorframe

With a tilt-up style door containing no hinges, you get less stability. There are no fixed connections to the doorframe other than a cylinder on each side of the doorframe. These cylinders do not pull the door downward, it just floats downward. Even the least amount of snow or debris under the doorframe or a frost heave on the outside ramp will result in the bottom of the doorframe sitting slanted and not level with the floor. When a door just floats down instead of being powered down by its cylinders and pump, the bottom seals cannot do an adequate job of sealing the door in the closed position. This creates a gap on one side and a tighter fit on the other side resulting in an open gap or crack that will allow daylight, dust, dirt, and snow to blow inside your building or even unwanted rodents to come inside.

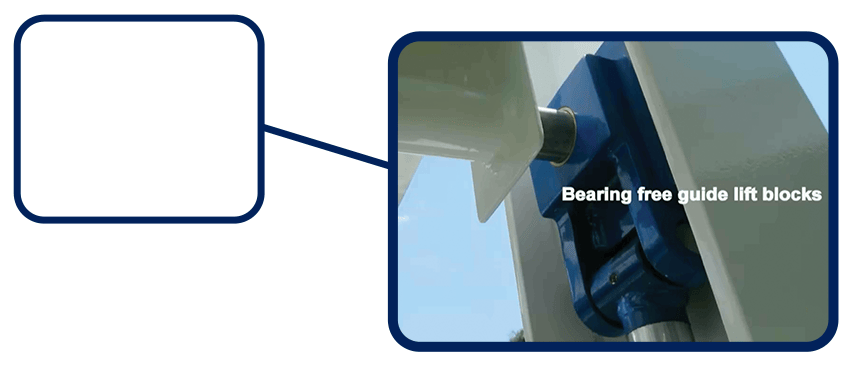

Tilt-Up Doors Have Two Lift Points That Support The Door, They Had Better Be Strong Enough!

The cylinders on these style doors that raise and lower the door are connected to a pin that is cantilevered off each side of the doorframe. Both pins and rollers carry the entire weight and loads of the door. These doors have two support points and two guide rollers!

The tilt-up doors have no hinges to balance and distribute the loads of the doorframe.

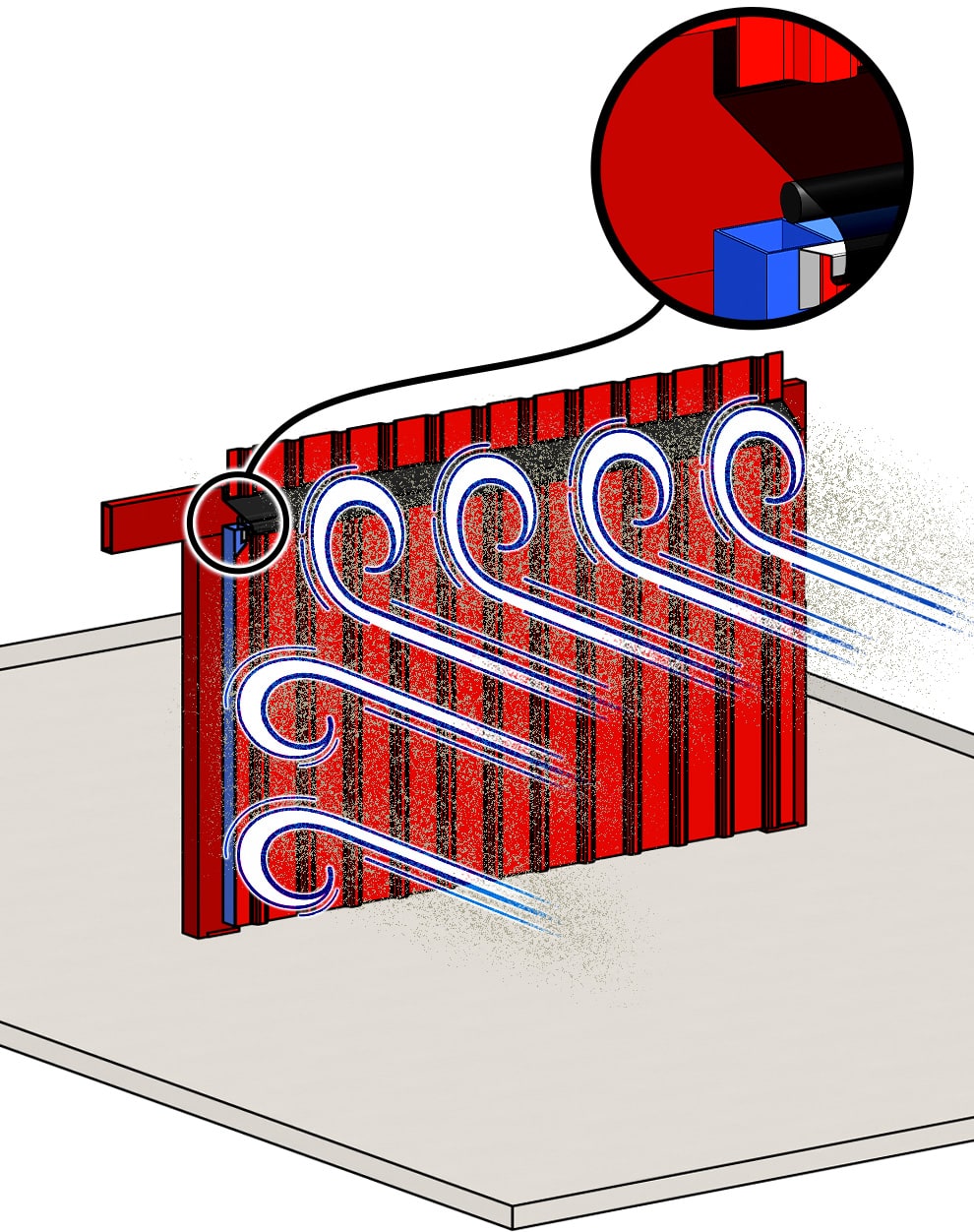

Keeping Outside Elements Out Of Your Building

By design, tilt-up doors do not contact the side columns, leaving a huge gap that needs to be sealed to keep the outside elements out of your building! When operating the door any slight movement from left to right will cause irregular gaps that are challenging to seal! The tilt-up door require two seals on both ends of the door. One seal mounts to the vertical column the other seal mounts to the doorframe. Both seals will be rubbing against each other when opening or closing. By design this door rotates as it opens - the doorframe rolls up and tilts inward into the building and the bottom tilts outward; both seals will be rubbing against each other as the door opens and closes. Maintaining a good seal can be a real challenge; keeping the weather seals intact and in place with every cycle!

Doors that do not seal well

- . . . Cost more to heat!

- . . . Cost more to cool!

Customers Are Not Happy When...

- Their equipment or airplane is covered with a layer of dust from the outside!

- Driving rain is getting through the seals into the inside of the hangar/building structure!

- They are losing valuable inside heat escaping through the seals on a hangar/building structure!

- They are losing valuable air conditioning escaping through seals on a hangar/building structure!

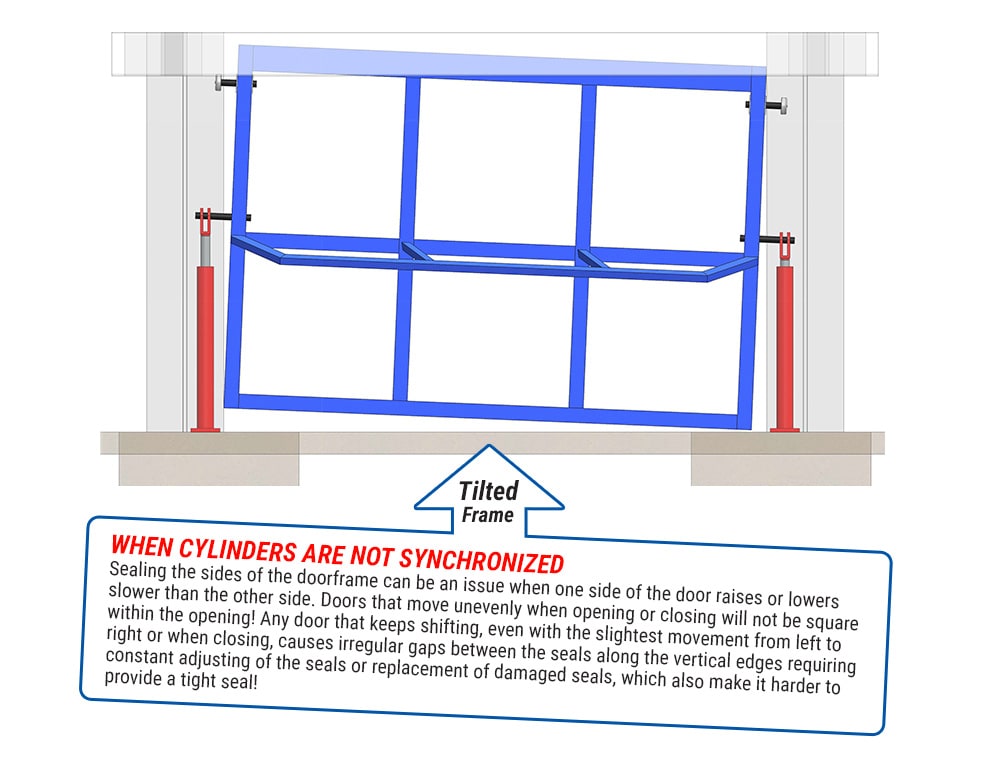

By Design:

- Tilt-Up Doors Don't Have Top Hinges

- When the Cylinders Get Out of Sync,

The Doors Come Down Unevenly?

Not So Weathertight

The large tilt-up doors can move left to right inconsistently when closing causing irregular gaps along the vertical edges, header and sill. The tilt-up door requires weather seals at the top and bottom, with double seals on the sides.

What Do You Lose When Your Door

Doesn't Have Top Hinges?

One word... Stability!

Big External Truss

Can Be An Obstruction

Testimonial

“My neighbor has an external truss in the middle of the door - when I taxi between the hangars, I have to watch out for the external trusses because they are at wing height”

Big External Truss Will

Need Ongoing Maintenance!

- External truss is an eyesore.

- Will require attention such as painting since the truss is exposed to the elements.

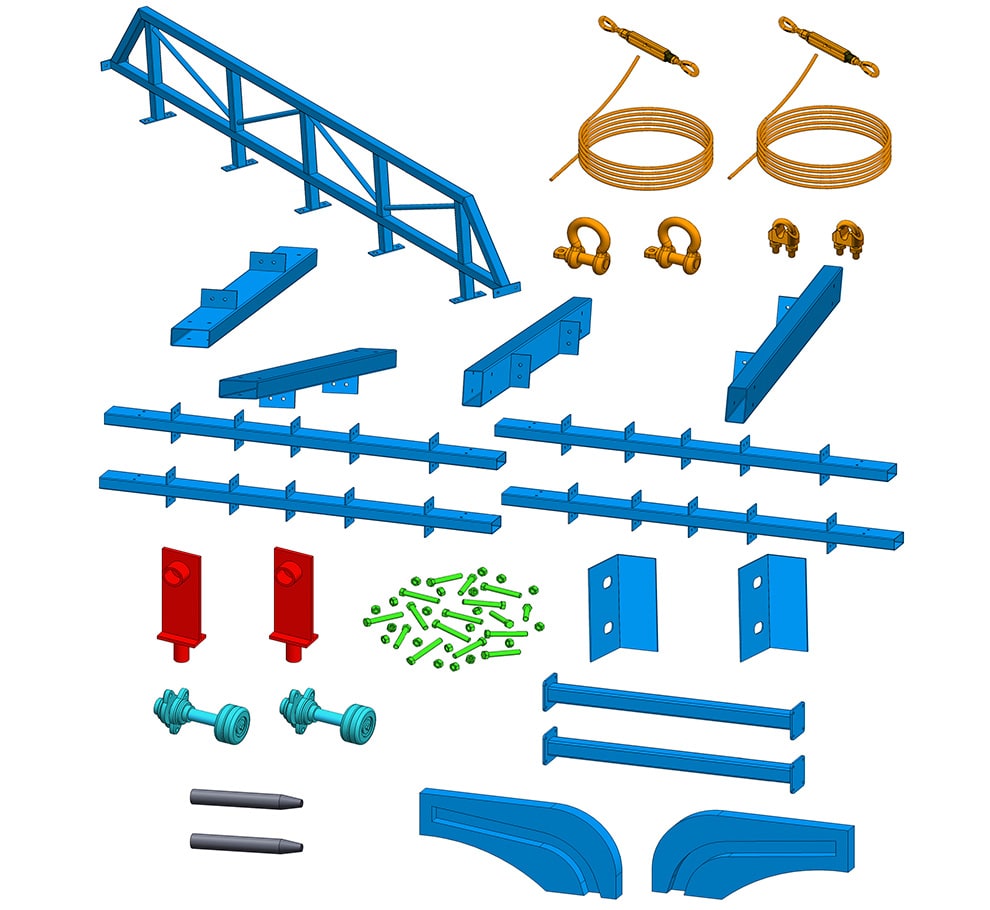

Tilt-Up Doors Come In Kits

Kit Doorframes... Need to be Assembled

Others companies ship their doors broken down as a bolt-together kit; a giant Erector Set with lots of bolts, small parts and cables to deal with! If by chance the kit is missing components or not assembled correctly it's gonna cost somebody extra time and money! Usually it ends up costing the end-user more when that happens!

Kit Door... Bolted Connections

Installation of bolts and cables on a moving doorframe is critical and is all up to the erector to do a good job. Are all the bolts tight? Did you miss any? Do I have the doorframe square? Did I bolt the truss in place? This all sounds like a real timely undertaking to install a kit door! Kit doors may save manufacturing time, but add more time for the installers to assemble the door at the job site! Schweiss doors are pre-assembled, pre-welded and delivered pre-hung within its own doorframe for easy installation.

Kit Door... Flimsy Bolted Connections Vs. Welded Connections

Will a kit door be as strong as an all-welded doorframe? Welds never work loose and are a much stronger and permanent connections - welds never need to be reinstalled or tightened. Schweiss doorframe members are shop-welded, the doors are delivered pre-hung within their own doorframe for easy install.

Here is What People Are Telling Us:

- “My door is hard to seal which cost more to heat... big energy loss!”

- “My hangar door needs to seal tight.”

- “I'm not going to spend thousands of dollars for a door that is hard to seal.”

- “I have bought 10 doors that don't seal well... I want to tell others!”

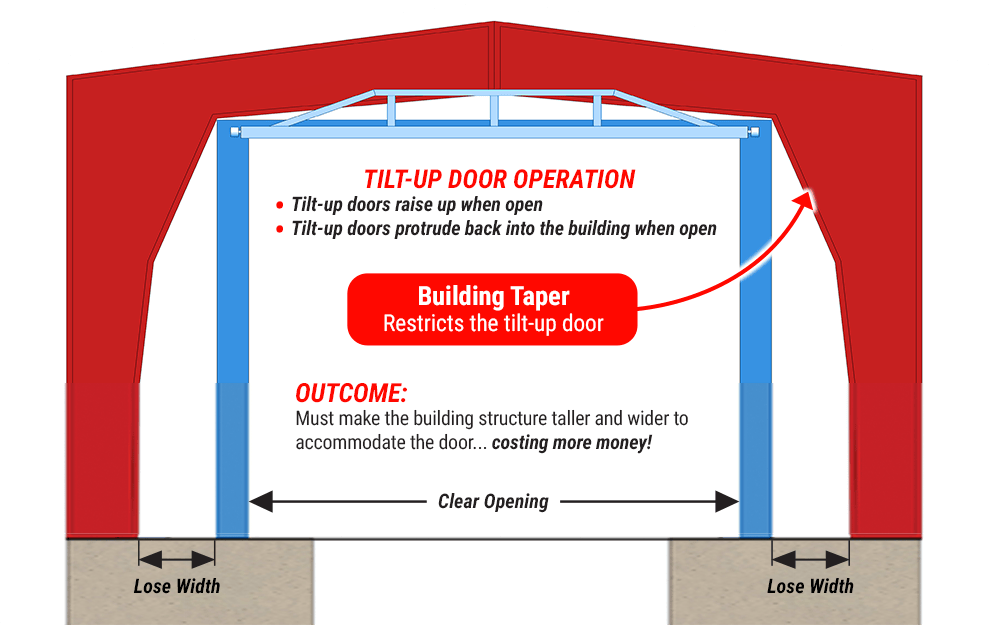

Building Restrictions With Tilt-Up Doors

Tilt-Up Door Vs. Hydraulic Door

Tilt-up Doors - Must stay clear of the building mainframe because the doors raise up

first then rolls back into the building.

Tilt-up Doors - Are restricted by the tapered building mainframe which narrows your

clear opening and requires a wider building to maintain the opening size needed.

Tilt-up Doors - Take up valuable headroom

Tilt-up Doors - Harder to seal

Require a wider building structure

Require a taller building structure

Require additional concrete footings to carry the loads

Schweiss Hydraulic Doors

Door Overview

THE IMPORTANCE OF . . . HINGES ON A DOORFRAME

The Schweiss hinge has a Robust design over tilt-up hydraulic doors that have no hinges! Schweiss Hydraulic Doors are designed with heavy-duty hinges that help carry the entire weight of the door when opening and closing! The advantage of heavy-duty hinges on a moving doorframe is that they distribute the weight of the doorframe evenly across the subframe header to give the door stability in all positions. By having the hinge run across the entire top of the door, the whole door is supported! It's all about surface area. Schweiss hinges help spread the forces over a broader portion of the doorframe and header lowering the stresses that are transfered to the hydraulic cylinders and components of the door!

Schweiss hinges give the door stability in all positions.

Schweiss... safety / stability / performance... no matter what size door.

Yes, when your door has inferior hinges you sacrifice the stability of the

doorframe making your door significantly harder to seal.

With that being said, common sense will tell you how important it is to have "the strength and functionality" of hinges connected to the doorframe!

HINGES SUPPORT THE DOOR IN ALL POSITIONS!

Cylinder Lift Points

Power Up And Power Down A Solid Connection Door Will Go Up & Come Down Evenly

Forces are on the Doorframe

The hydraulic cylinders on Schweiss doors that raise and lower the door are connected to the doorframe between two vertical frame members. These vertical frame members balance the weights and forces on the hydraulic cylinders. Spherical bearings are also used to accommodate any flexing, making a strong and safe connection! Schweiss includes 6 to 24 hinges ( depending on the door size ) that are connected to the doorframe to help carry the weights and loads of the door! Schweiss doors utilize hinges to provide a strong connection and safe door! Schweiss hydraulic cylinders have a direct force on the doorframe, not on a cantilevered pin that sticks out the side of the doorframe!

Hinges and Cylinders Provide Stability To The Doorframe In All Positions.

No Lost Headroom . . .

Schweiss Hydraulic & Bifold Doors

Top hinges are included on both doors.

A Customer Told Us:

“The headroom loss from a tilt-up door when compared to a hydraulic door was a deal breaker for me.”

Gain Headroom

Less Restrictions With Hydraulic Doors

Hydraulic vs. Tilt-up Doors

- Hydraulic Doors - Utilize the full width between building columns

- Hydraulic Doors - Lose no headroom

- Hydraulic Doors - Mount on the face of the building columns

- Hydraulic Doors - Swing out when open

- Hydraulic Doors - Allows you to keep your building costs down

- Hydraulic Doors - Do not require additional footings

- Utilize building space better

- No restrictions

- Save on building costs

Hydraulic Doors...Easier To Seal

Hydraulic Doors...“Overlap”

Doorframes are wider than opening, leaving NO gap on each side

All Schweiss Hydraulic Doors Are Easier To Seal

Seals Tight

SCHWEISS WEATHERTIGHT DOORS

Schweiss doors are extremely weathertight and designed so the doorframes overlap by two inches on each side column making it easy to seal on the sides of the doorframe. The two hydraulic cylinders pull and power the doorframe securely and seal against the door columns! Unlike most tilt-up doors, Schweiss doors are powered down. Tilt-up doors float down into closed position and the doorframe does not overlap anything, leaving a huge gap that needs to be sealed off resulting in dust and dirt blowing through the gaps and cracks.

Schweiss Design

Note: Schweiss doorframes overlap the side columns two inches, not allowing any gaps! Doors are easy to seal when the doorframe overlaps the column; it's harder to seal gaps when the doorframes do not overlap the columns!

“The Thing I LIke Most About My Hydraulic Door.”

“It overlaps on the outside of the building, using wind pressure as an advantage. The wind pressure pushes the doorframe into the building columns, creating an even better seal.”

SCHWEISS WEATHERTIGHT DOORS

Schweiss doors are extremely weathertight and designed so the doorframes overlap by two inches on each side column making it easy to seal on the sides of the doorframe. The two hydraulic cylinders pull and power the doorframe securely and seal against the door columns! Unlike most tilt-up doors, Schweiss doors are powered down. Tilt-up doors float down into closed position and the doorframe does not overlap anything, leaving a huge gap that needs to be sealed off resulting in dust and dirt blowing through the gaps and cracks.

Schweiss Design

Note: Schweiss doorframes overlap the side columns two inches, not allowing any gaps! Doors are easy to seal when the doorframe overlaps the column; it's harder to seal gaps when the doorframes do not overlap the columns!

“The Thing I LIke Most About My Hydraulic Door.”

“It overlaps on the outside of the building, using wind pressure as an advantage. The wind pressure pushes the doorframe into the building columns, creating an even better seal.”

Less Parts . . . No Bolts . . . Less Time to Install

Schweiss Doors Are Not An Erector Set

From The Factory

Solid, All Steel Welded Frame

Doors Come Pre-Assembled And Welded At Factory

All quality control is done at the factory. No bolts to mess with!