Steel Building

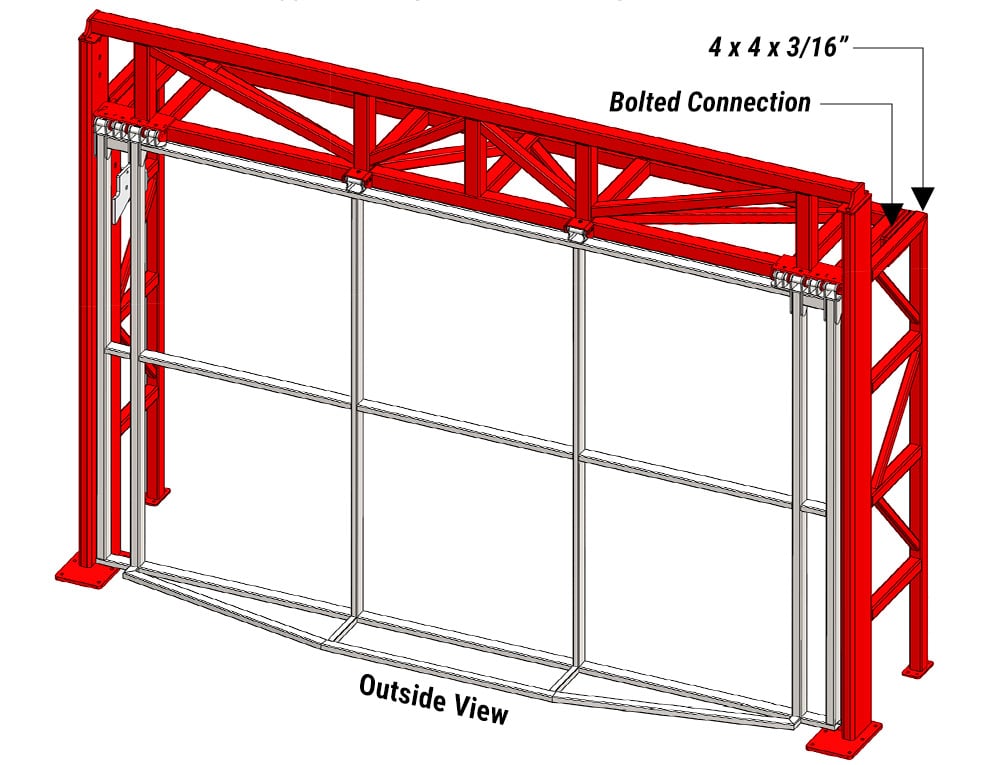

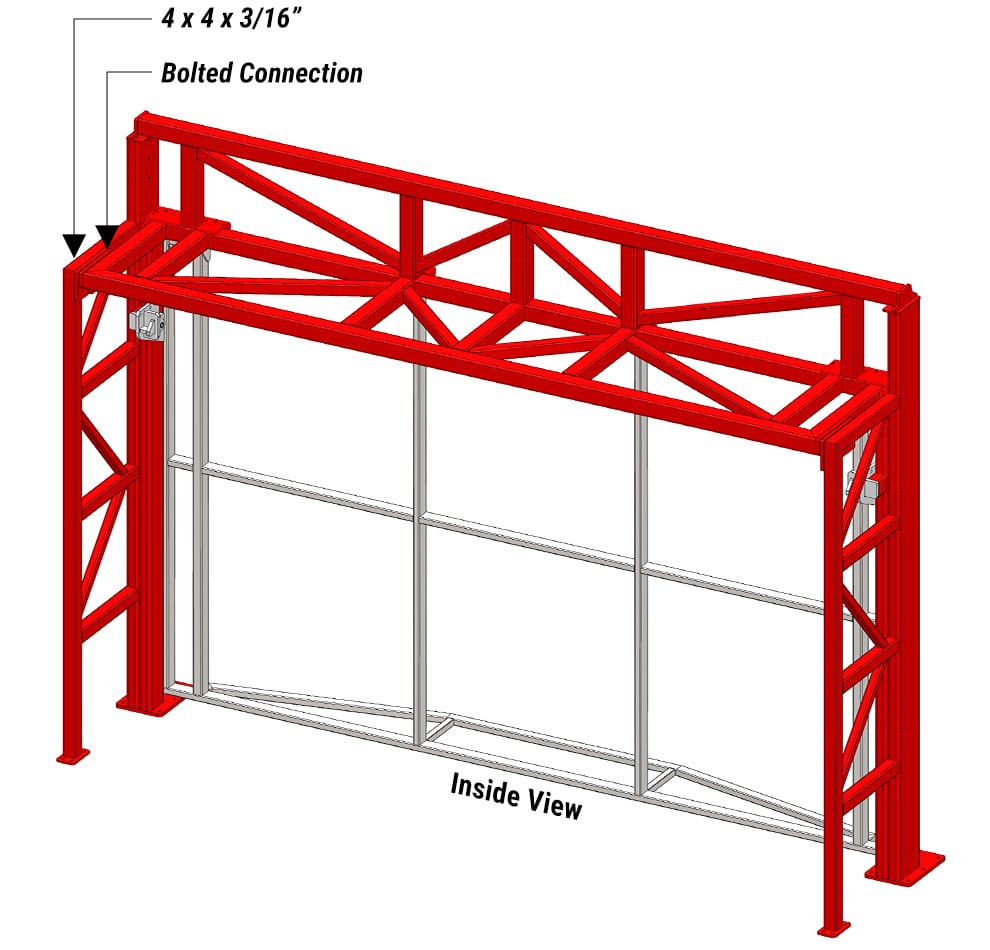

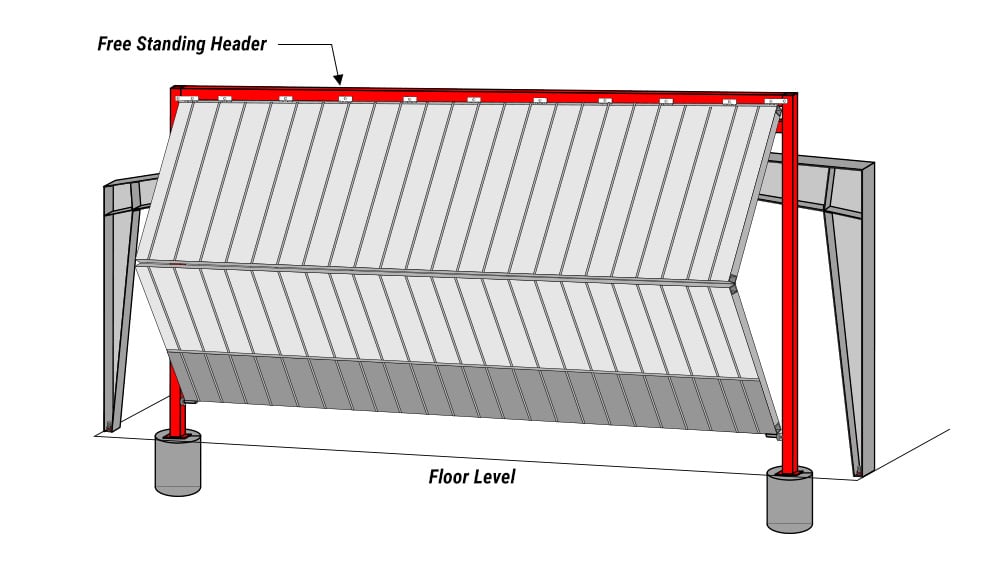

Free Standing Header

Steel Building Free Standing Header

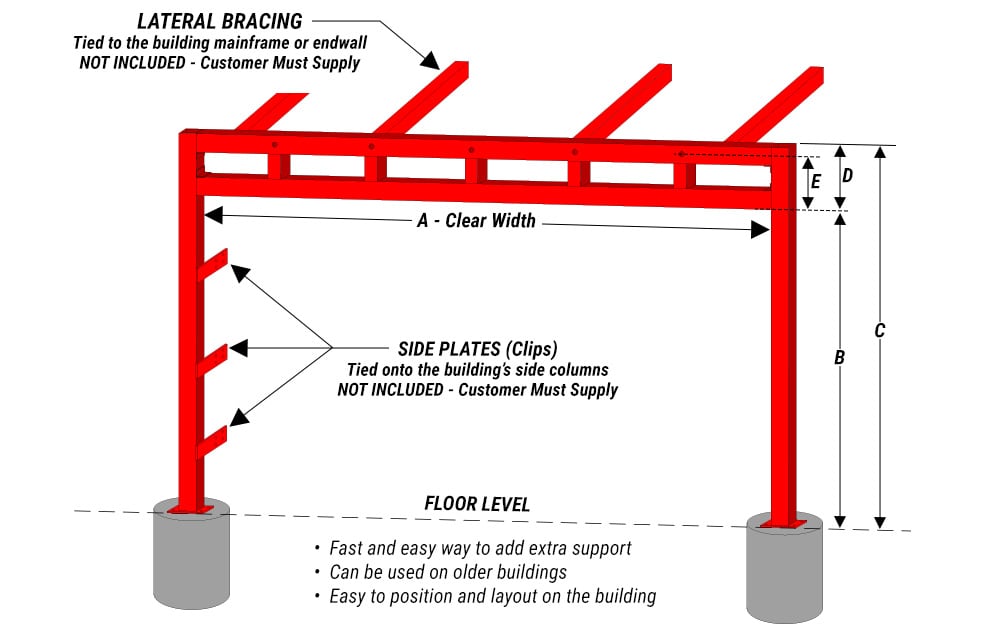

✔ Fast and easy way to add extra support

✔ Can be used on older buildings

✔ Easy to position and layout on the building

✔All-in-one

✔Self-supporting

✔Attaches to your building

✔Includes - Endwall girts/wind bracing

Free Standing Header Overview

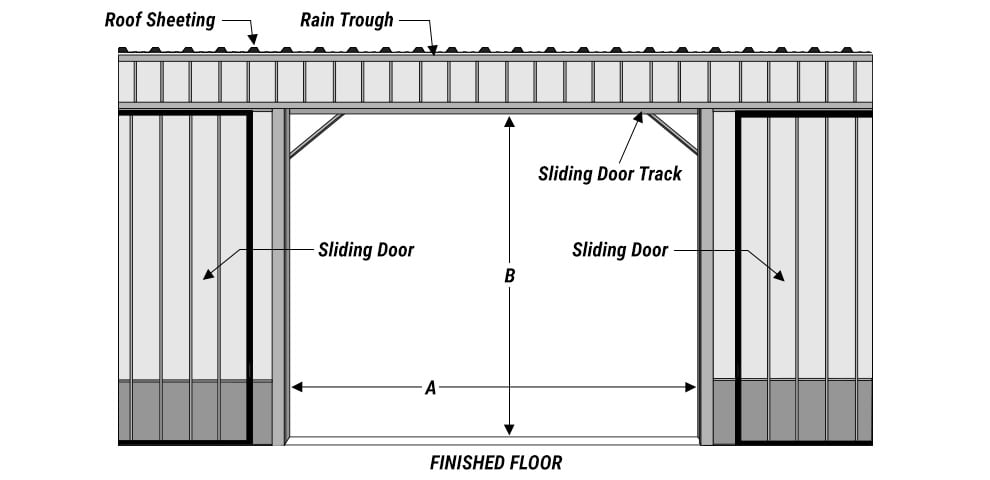

Steel Building - Overview

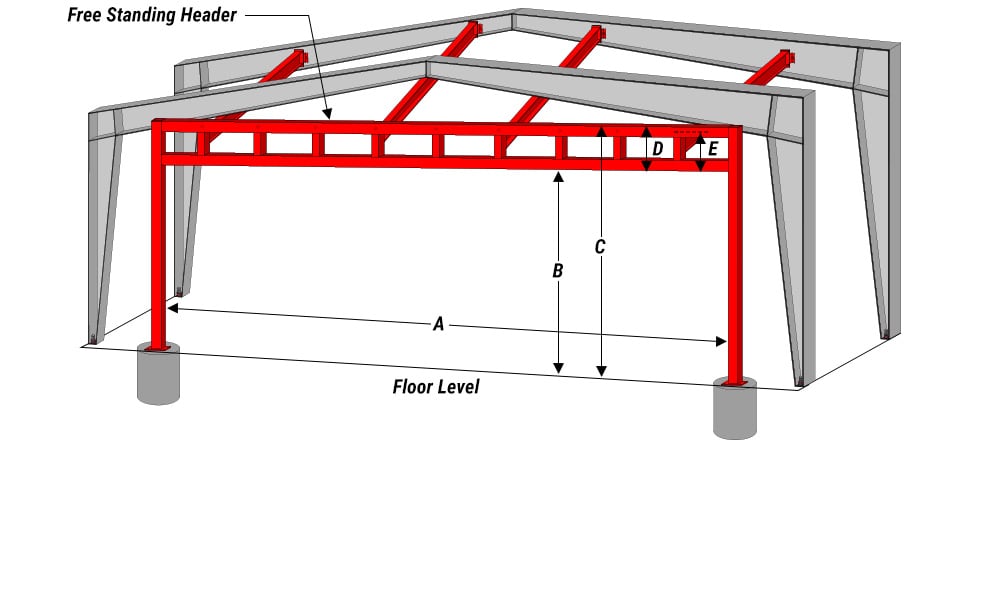

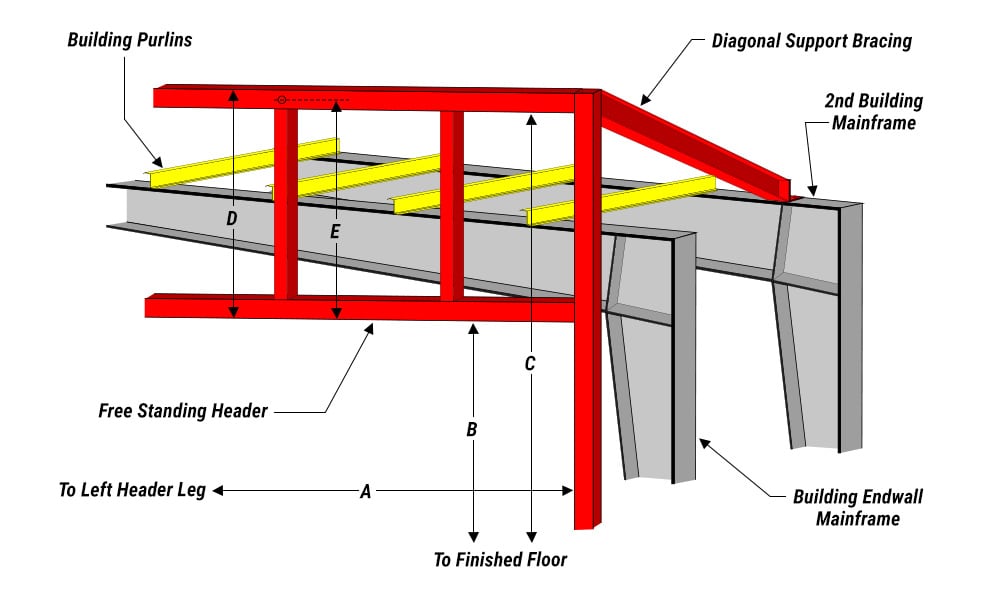

Call Outs / Specs

A = Distance between the legs will be your clear opening width.

B = Distance should be the same as your clear opening.

C = Total height of your header = B (clear opening) + D (Wedge).

D = Distance of your wedge.

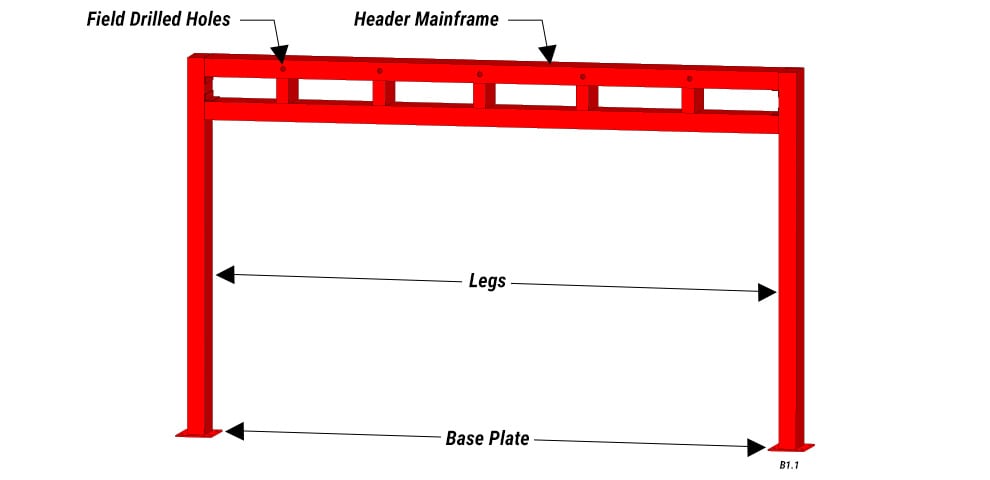

E = Distance from the top of the clear opening to center of the bolt holes (field drilled).

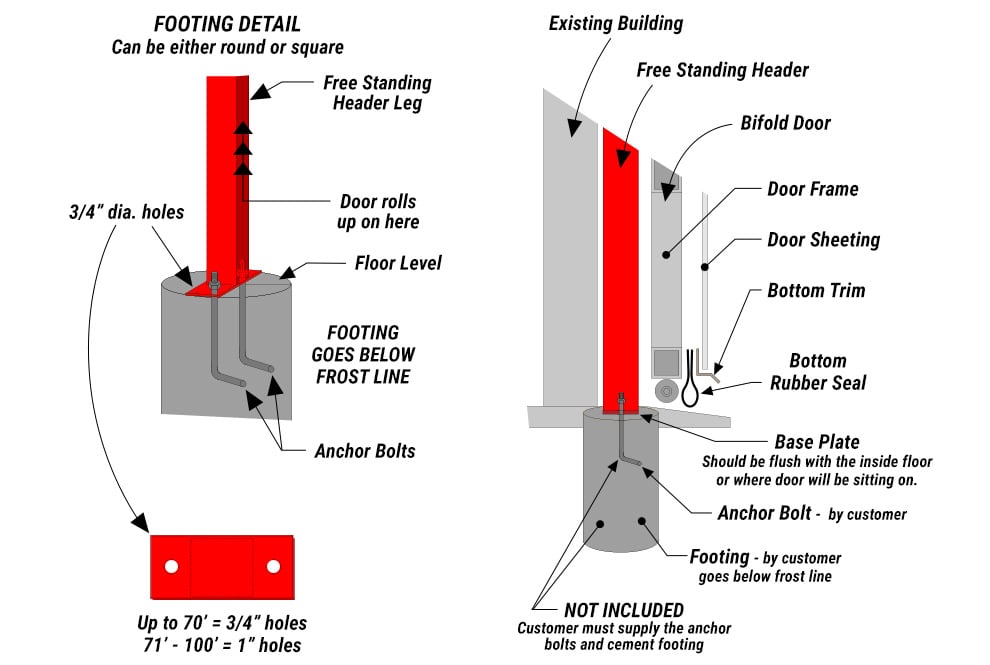

Base Plates

8” x 8” Steel Plate x 1/2” thick material (w/pre-drilled holes).

Base Plate should be centered on legs.

Base Plate must be flush with the back of the legs.

The legs must be welded to the main header frame.

Pre-welded angel irons are at each of the four corners for added strength.

Caution!

The free standing header is to provide a flat smooth suface to mount the Hydraulic and Bifold Door to! The customer must provide the proper member sizes to hold the weight of your door on the header! Schweiss Hydraulic or Bifold Doors are not responsible for the structural strength of the free standing header! The free standing header must be attached to the building, and the building must support the vertical and horizontal weight of the door - tie the header and side columns to your building. Provide a solid footing under the legs or the free standing header.

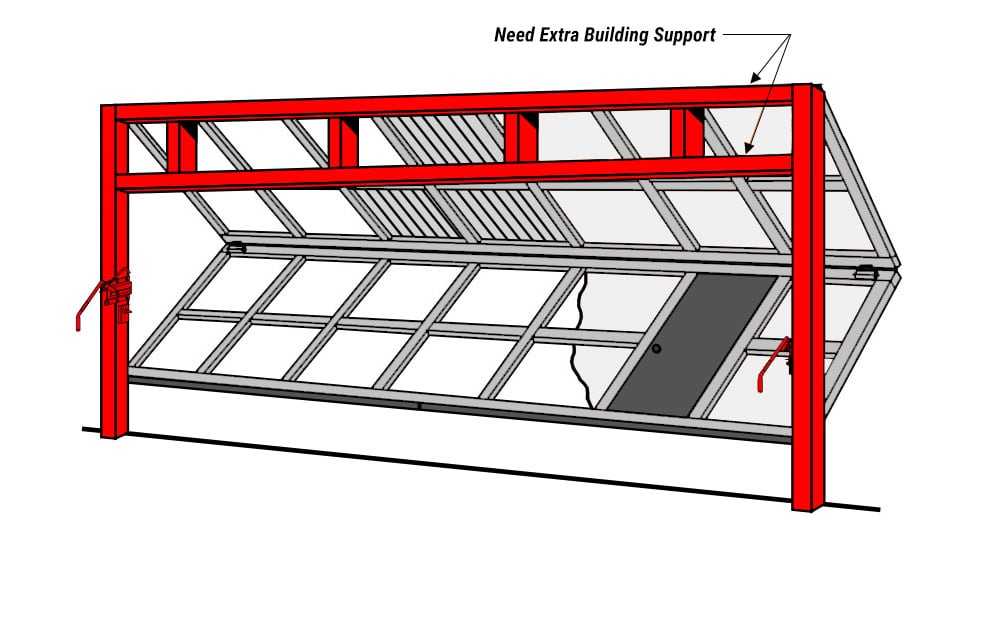

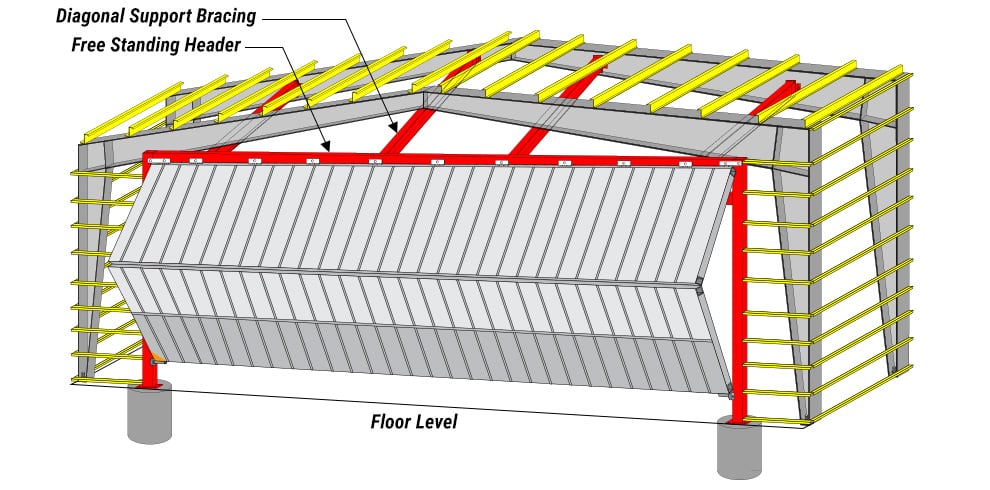

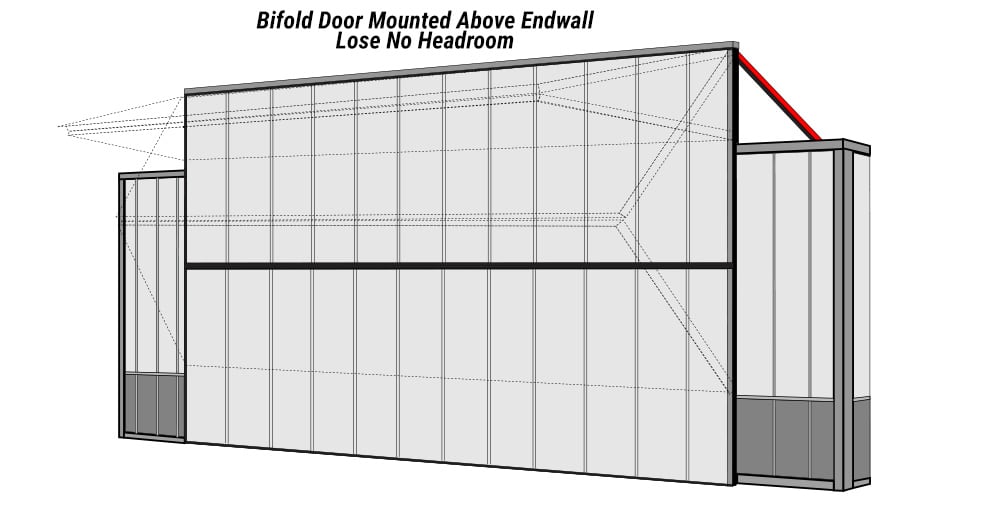

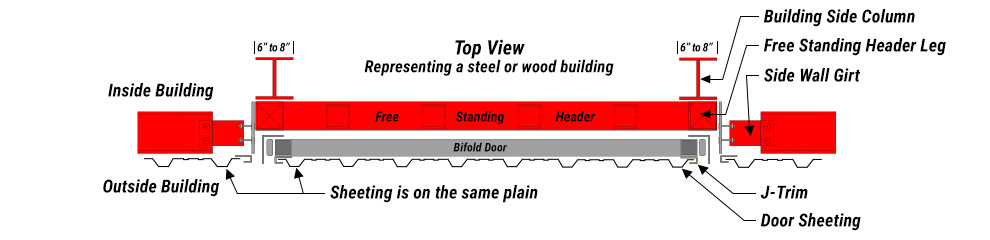

Steel Building Header With Bifold Door

Steel Building - Shown With Bifold Door

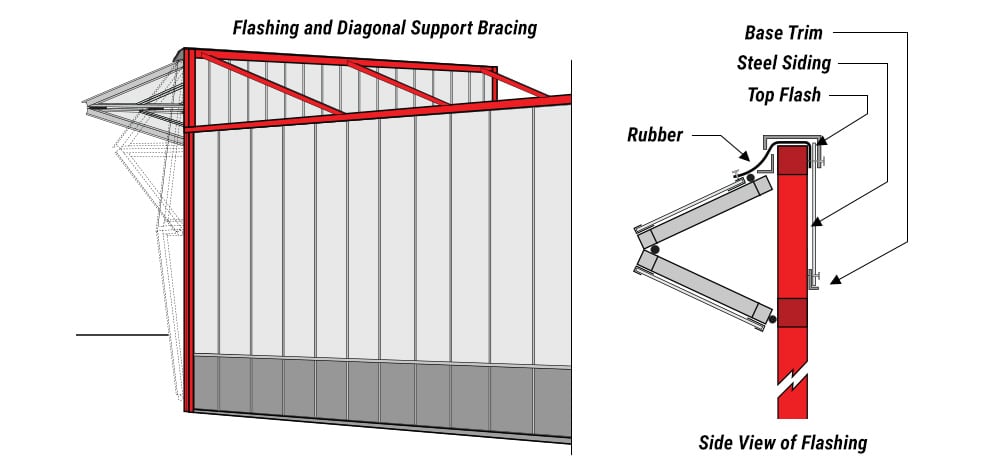

Header Above The Endwall

Flashing and Back Bracing Above Endwall

Bifold Door Above Endwall

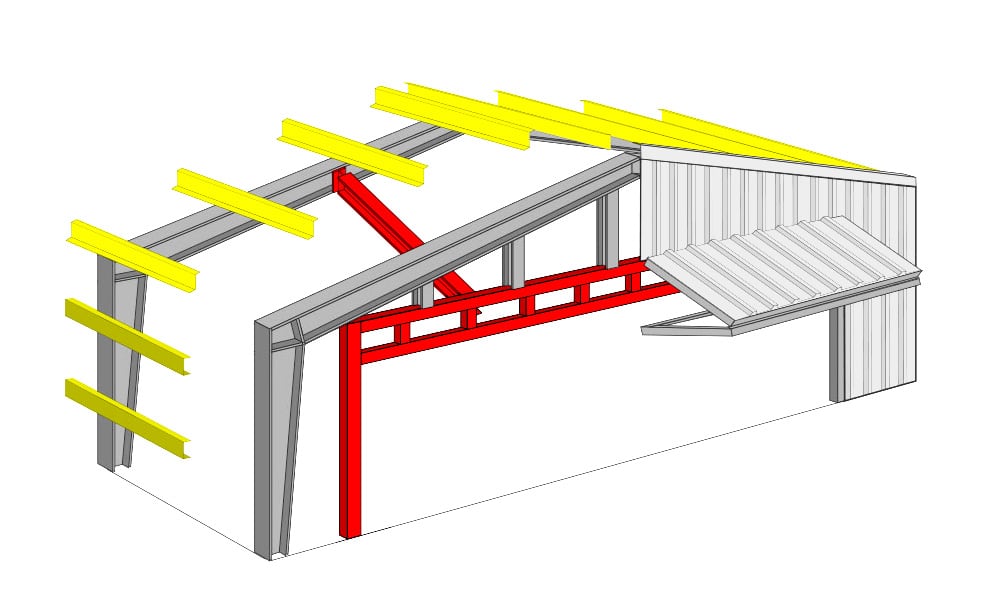

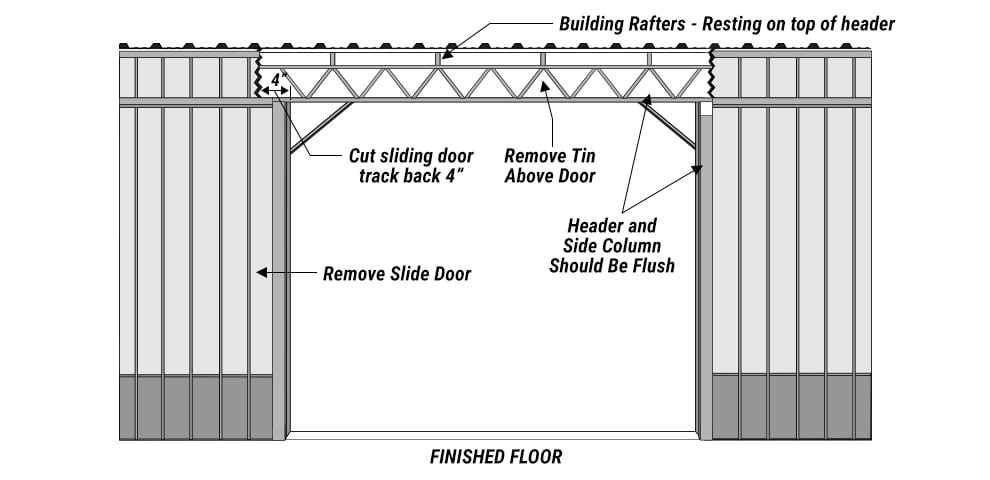

Preparing Building Side Wall

Before - Preparing the Side Wall

After - Preparing the Side Wall

Talk About Free Standing Headers

Talk About Freestanding Headers

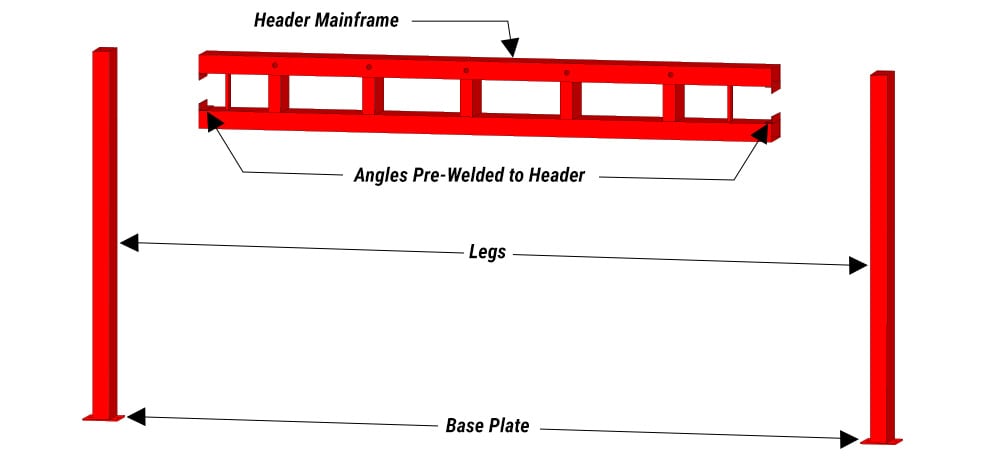

Schweiss Bifold Doors manufactures the entire freestanding header. You may retrofit it to your building endwall or sidewall. The freestanding header is a quick and easy way to prepare your building for a bifold door. It consists of two side columns and the main header frame.

The freestanding header must be attached to the building and the building must be able to support the vertical and horizontal weights of the bifold door. You must tie the header and side columns to your building and provide a solid footing under the legs of the freestanding header.

Why Use a Freestanding Header?

- It's a nice easy way to prepare an existing building for a bifold door.

- It provides a clean, flat, flush surface to attach your bifold door to.

- The freestanding header will offer extra strength.

- It provides a nice straight and level place to attach your door to, especially on those older buildings.

- It's a quick fix - It's easier than remodeling the existing end wall for a bifold and many times cost effective!

- It's a trade off- You would have to build a header up to your existing end wall and that's not free

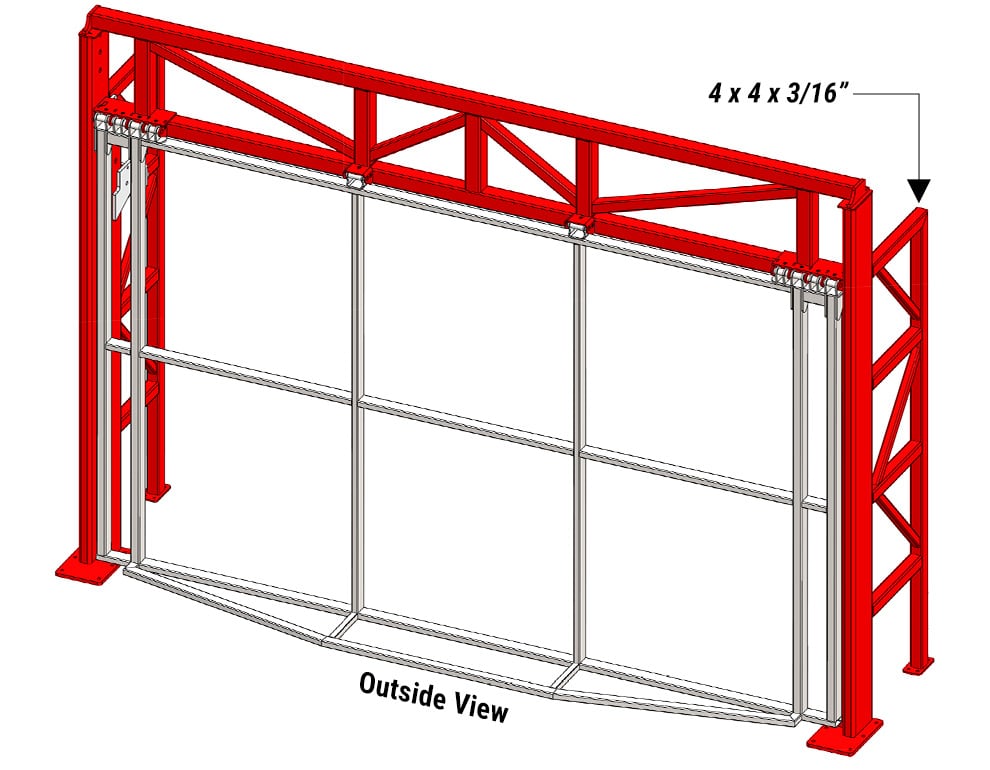

(labor and material?) - Freestanding headers are made out of 4” x 4”x11 gauge tubes (2 across the full widths, 2 legs and base plates).

- Larger freestanding headers are made out of larger member sizes.

- The header comes all welded together. You must field-weld or bolt both of the legs on.

Installation of the Freestanding Header

- Installation is easy; attach the legs to your side columns and tie the header back into your existing building.

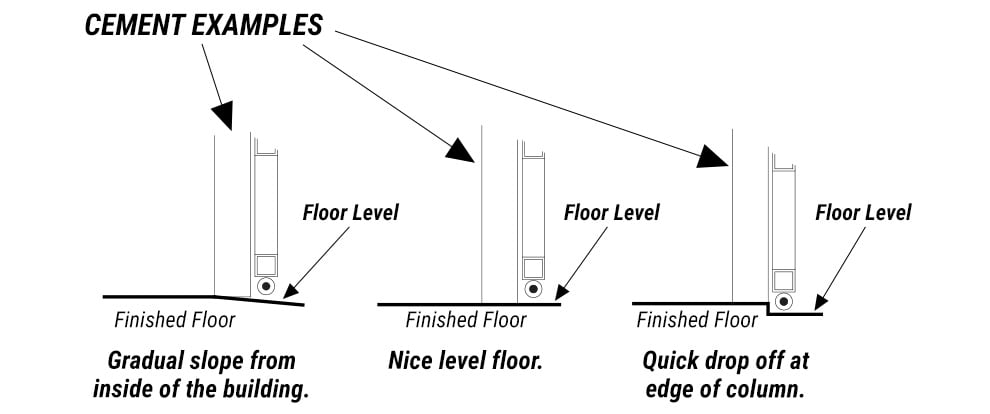

- Anchor the base plates to your concrete footing with anchor bolts.

- If there are no footings for smaller doors, just attach the side columns to your building posts or columns.

- We provide a step-by-step installation manual that is very easy to follow.

- If you want to build your own header we will provide you drawings on how to build it yourself.

- Take pictures to send to the factory of your large opening, especially for larger header questions.

Important:

- The customer, contractor/owner, and the building manufacturer are responsible to ensure that the building's structural design is capable of handling all the imposed loads that the bifold door exerts to your door header, endwall, and building.

- When your bifold door is in the full open position, the bifold door tends to pull away from the building at the hinge line; exerting considerable horizontal loads on the building structure in the open position.

- Your building header design must meet standard deflection and strength criteria, both in vertical and horizontal directions to support the bifold door in all positions.

- Schweiss Bifold Doors will provide you with those loads that are applied to your building and door. We will provide you with our A-1, A-2, A-3, and A-4 spec sheets for your actual measurements, movements, weights, and hinge locations.

Header Assembly and Overview

Assembly

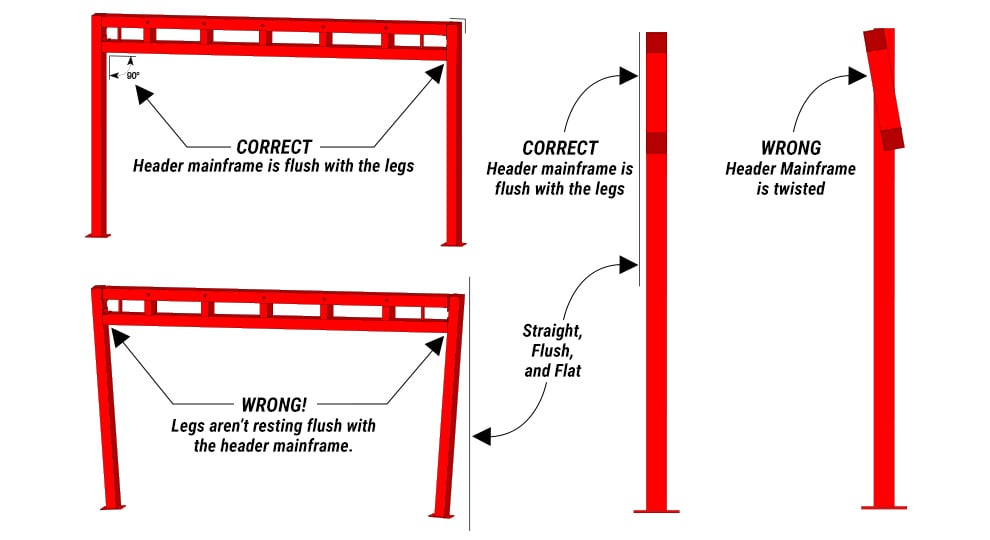

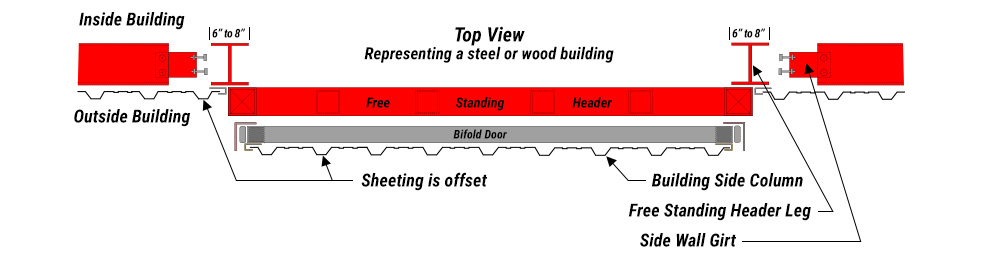

Slide each leg against the header mainframe. It is very important that the legs be straight, flush, and flat with the header mainframe.

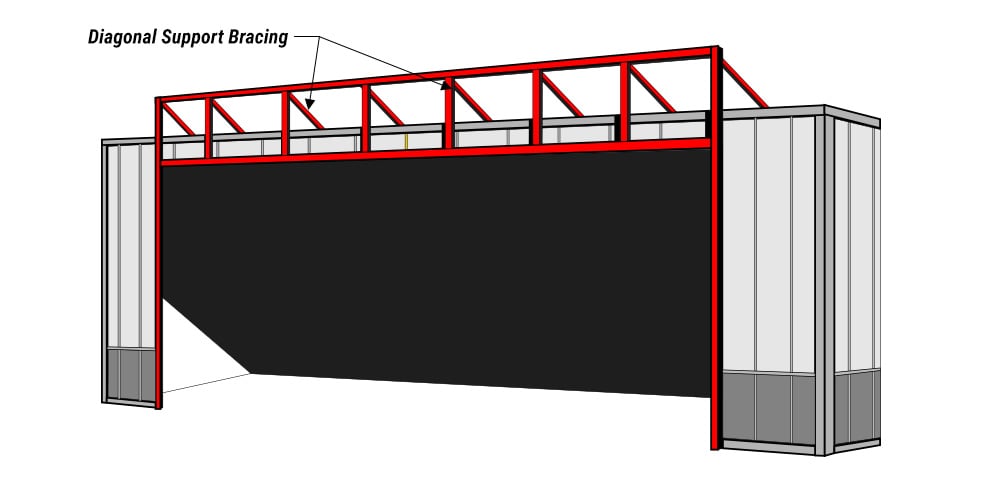

Finished Look

This is the way your free standing header should look after you assemble it.

Header Legs Must Be Straight

It is very important that the legs be straight, flush and flat with the header mainframe

Header Bracing

How to tie your free standing header back into the building. Lateral bracing and side plates aren't furnished by Schweiss Bifold Doors. The customer must supply these methods of tying the header with the building.

Concrete Footings For Header Legs

Free Standing Header Layouts

Outside and Recessed Headers For Wood Or Steel Buildings

Schweiss Hydraulic or Bifold Doors manufactures the entire free standing header. You may retrofit it to your building endwall or sidewall. The free standing header is a quick and easy way to prepare your building for a Hydraulic or Bifold Door. It consists of two side columns and the main header frame.

You, the customer, must provide the proper member size to hold the weight of your door on the header.

Schweiss Doors is not held responsible for the structural strength of the free standing header.

The free standing header must be attached to the building and the building must be able to support the vertical and horizontal weights of the Hydraulic or Bifold Door. You must tie the header and side columns to your building and provide a solid footing under the legs of the free standing header.

Outside Mount Header - Layout

Recessed Mount Header - Layout

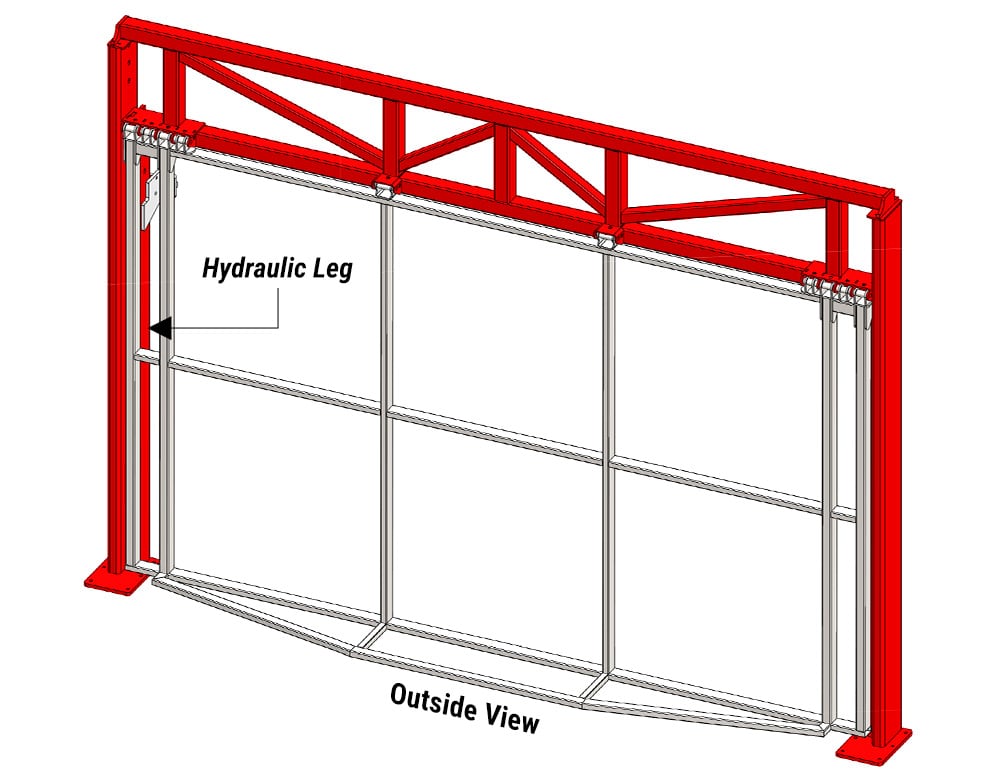

Free Standing Header - Hydraulic Legs

Option 1

Hydraulic legs with truss above header tube.

Option 2

Hydraulic leg with truss above header tube and rear support bracing welded to side legs.

Option 3

Hydraulic leg with truss above header tube and rear support bracing welded to side legs and header tube.