The Food Wagon Door Opens With A Hand Drill Or By Hand; No Electricity Is Needed!

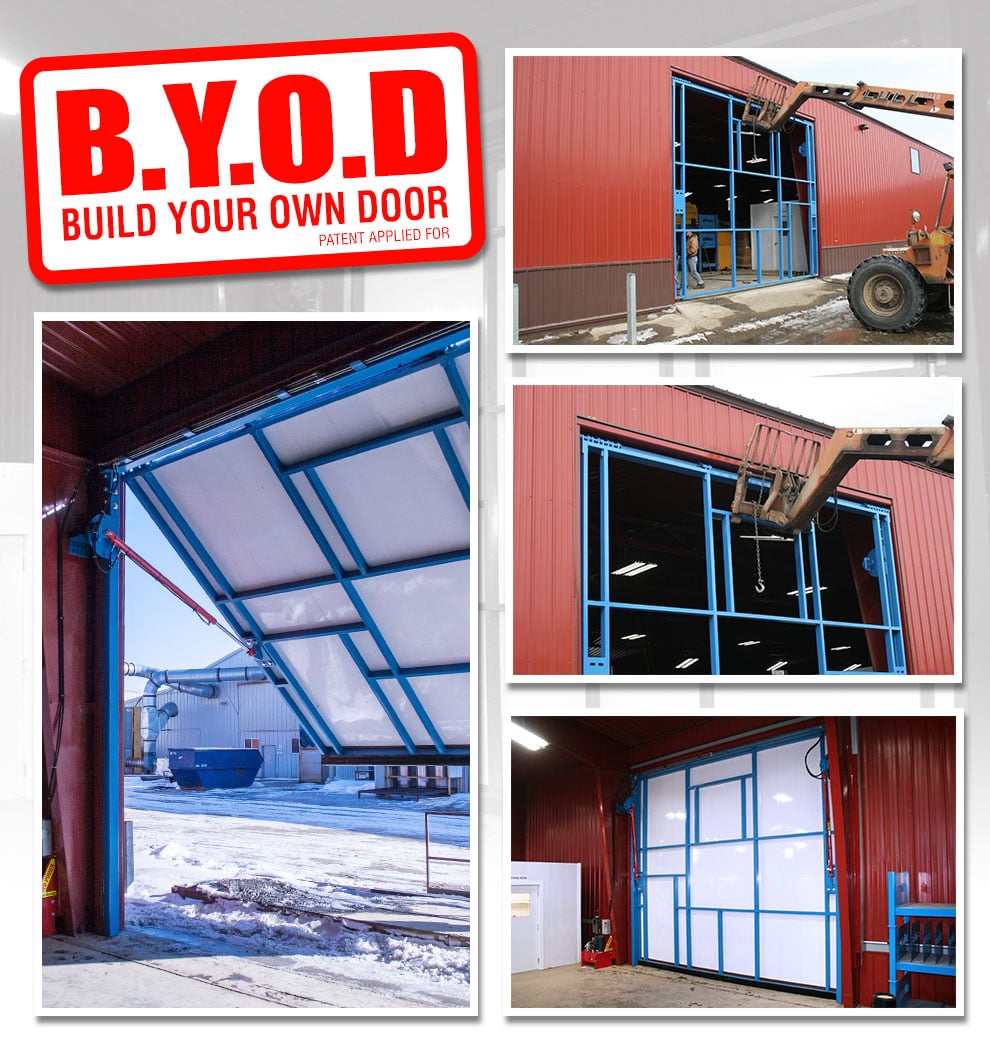

The Knights of Columbus do more than just serve the Lord; they also serve the community. Here in Fairfax, Knights of Columbus Men's Catholic Fraternal Council's 1625 members put their faith in action by just completing construction of a 10 ft. x 20 ft. food wagon kiosk with a small manually operated hydraulic door that will be used for St. Andrew's Catholic Church functions.

The KC's became aware of a need for this food wagon after being approached from some individuals from the Franklin Catfish Days committee asking them if they could do something to replace their 40-year-old food wagon that had seen its better days.

“Vic Serbus from Franklin told us they were no longer going to be able to use their lunch stand. At our KC meeting I told our members we could put a lunch stand together. I went to work looking for trailer that we could use as a base for the lunch stand. We were lucky when Frank Ziegler, Jr. donated his John Deere implement trailer. Vic and I came out to talk to Mike Schweiss at Schweiss Doors. Mike said if it's for the KC's and Catholic Church he would be able to donate a lot of the materials, tools and some manpower to design it and help get it started,” said George Wendinger.

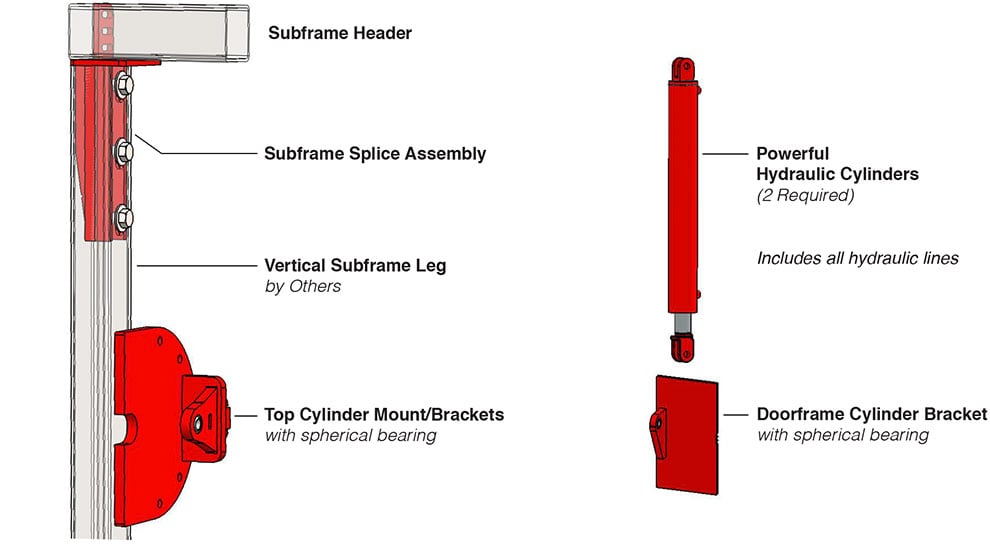

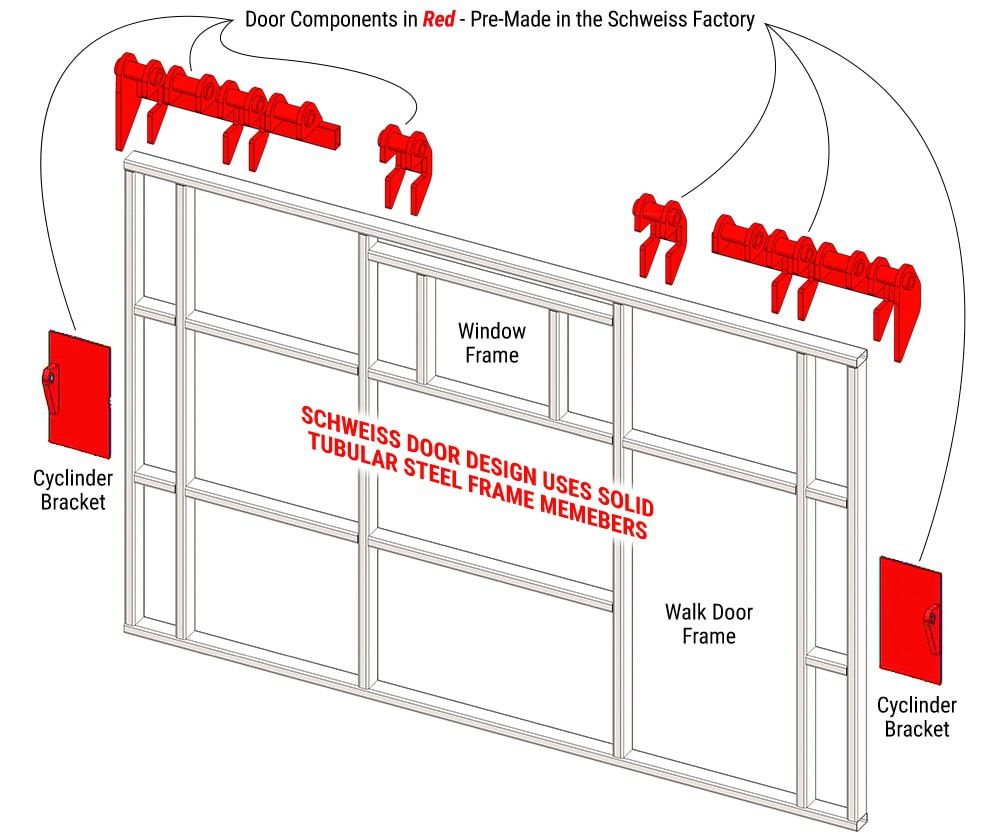

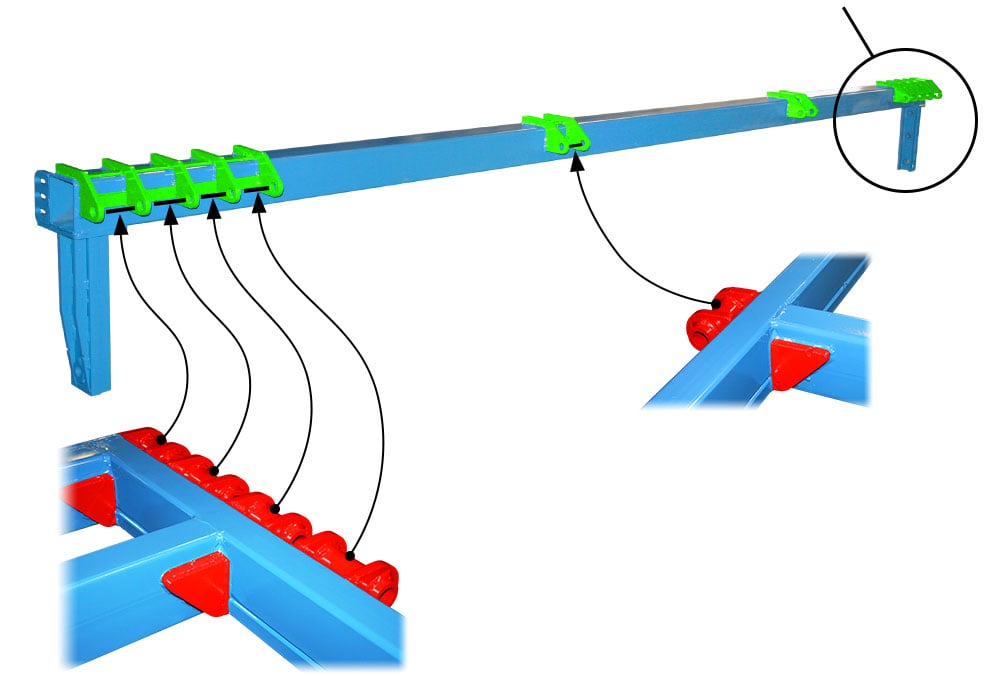

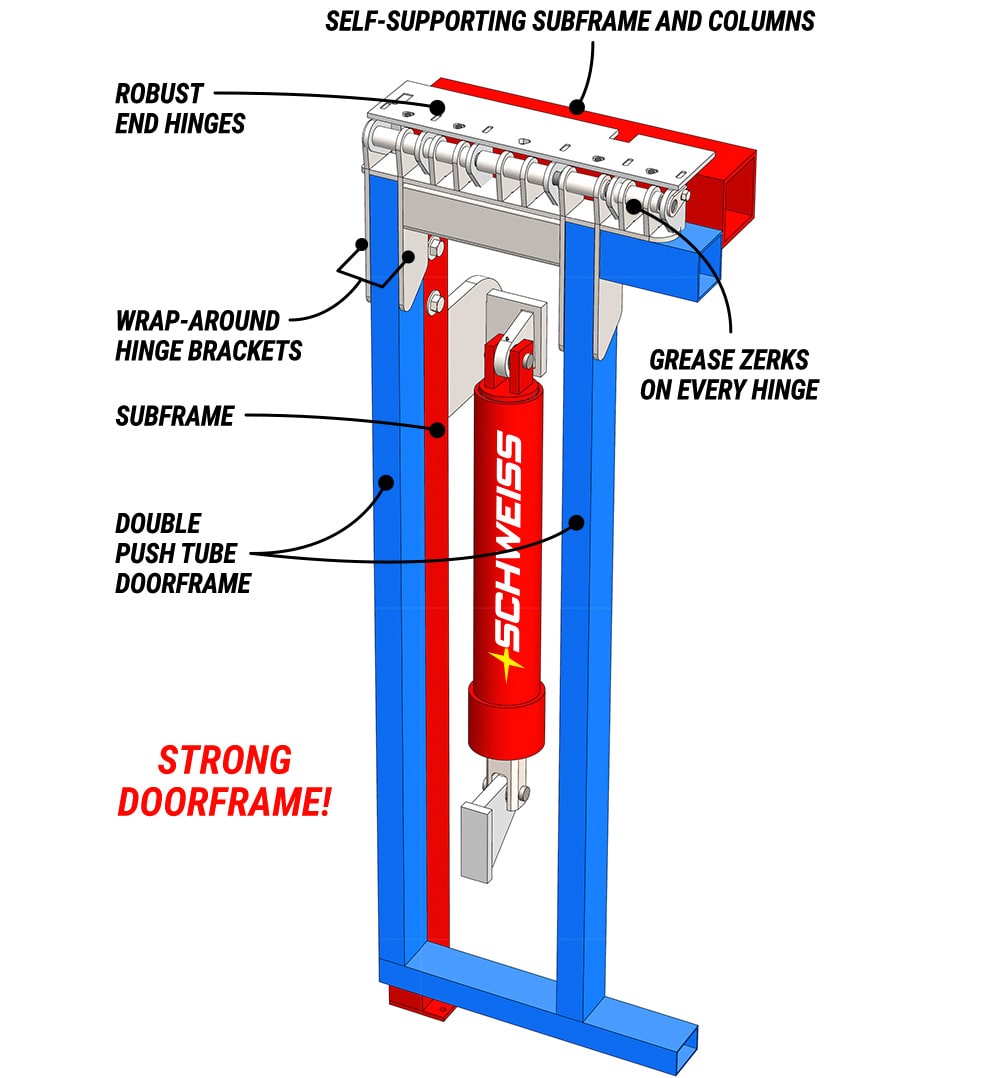

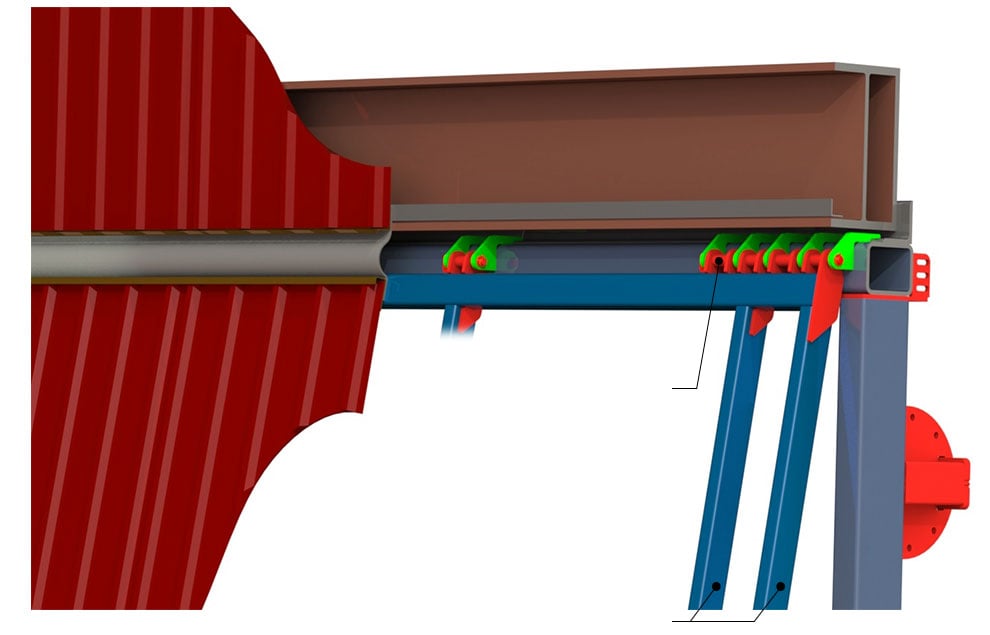

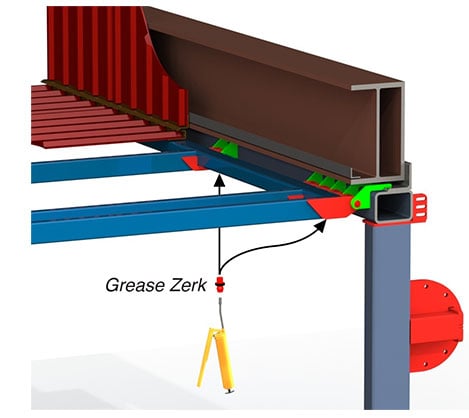

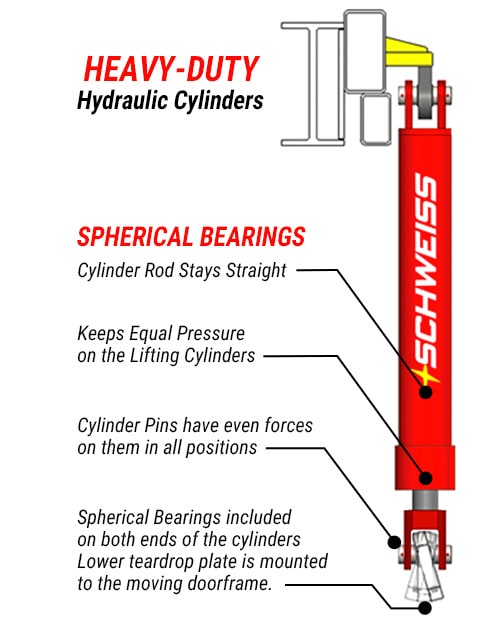

After Jon Sandman came up with a computer design, Joe Volz at Schweiss Doors went to work welding some 1 1/2-inch x 1 1/2-inch tubing to build the steel frame. Schweiss provided some of its coated interlocking insulated panels, and a manually opened hydraulic door at the rear of the lunch wagon that doesn't require electricity to operate. Outdoor barbequing and grilling equipment can be stored in the back; no cooking is done inside the food wagon.

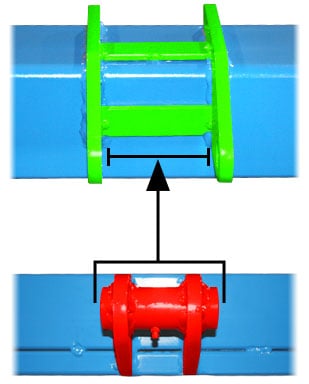

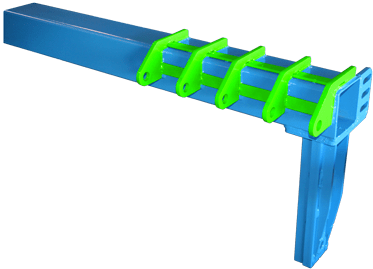

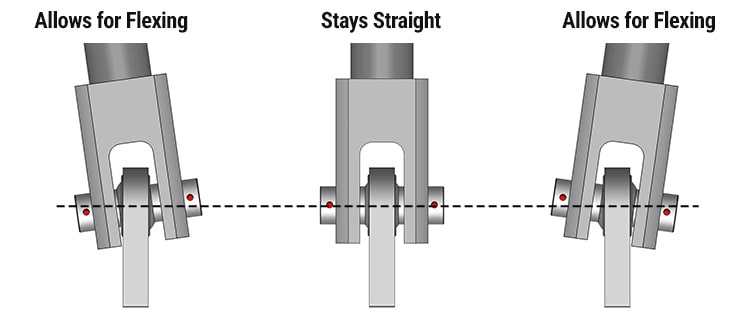

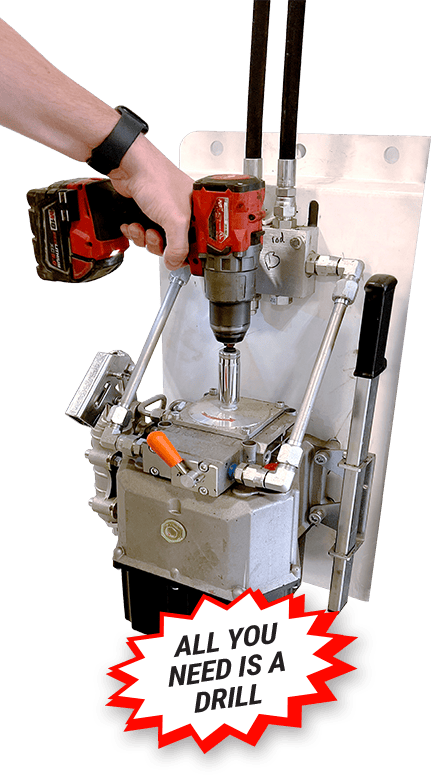

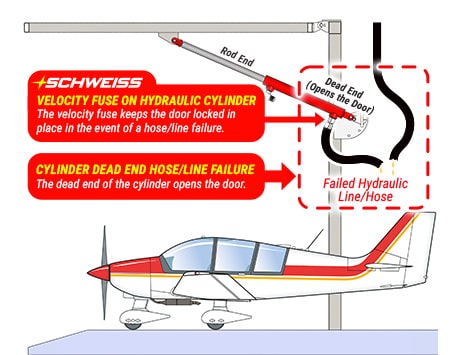

“What's unique about the operation of the food wagon hydraulic door is the incorporation of a special compact hydraulic pump unit that tucks into the back corner near the door. The door can operate with a battery-operated hand drill or can be manually operated; no electricity is needed! This compact pump works together with one hydraulic cylinder to easily lift the rear food wagon door as well as sealing the door weathertight when closed. When the door is open, it provides a nice, sheltered and shaded canopy” said Mike Schweiss.

Schweiss didn't do all the work, Mike Beranek, a retired 21-year employee at Schweiss Doors estimated that more than 75 volunteer man hours between about a dozen people were put into the project and with others involved, probably 150 total man hours were needed. Volunteers attached the outside skin, insulation, particle board covered by vinyl flooring. A 6,000 BTU air conditioner was installed, and a small refrigerator and freezer will be placed inside. After the food wagon was painted, some KC decals were applied to the outside.

“The KC's definitely want to thank Mike at Schweiss Doors for his more than generous help in designing and manufacturing of this food wagon,” said Beranek. “We are very fortunate to have others like Tom and Jerry Jandl, Mike Vait and Father Bruno involved who will also be present to help at Catfish Days.”