CONTACT US

City of Sauk Centre approves bifold

liftstrap conversions on 11 hangar doors

The Sauk Centre Municipal Airport has two rental hangars with 11 Schweiss bifold doors in each. The city decided that after having to constantly replace frayed cables that it was time to upgrade to a safer liftstrap conversion on 11 of the older hangar doors. The other hangar building was initially installed with liftstrap/autolatch doors.

Things are running much smoother at the Sauk Centre, Minnesota Municipal Airport now that they have retrofitted and upgraded all their cable hangar doors with Schweiss liftstrap conversions. A total of 11 bifold doors all on one rental T-hangar now lift quieter, faster and safer.

“ Our newer hangar building already has liftstraps and autolatches on its 11 doors. The strap doors are safer. With the old cable system, if you would lose a cable one half of the door would shift and get stuck. If a strap would break - we haven't had that issue at all - the door will continue work fine and safely. The other side of it is lack of maintenance. We probably put new cables on two doors each year. This eliminates all that time and maintenance out there which is helpful for us. ”

- Ben Clink, Public Works Supervisor

City of Sauk Centre, Minnesota

City of Sauk Centre Public Works Supervisor, Ben Clink, said the spark to get the liftstrap conversion originally came from suggestions initiated from the maintenance department.

"The older of these two hangars had bifold cable doors installed in 2000. We have an FBO that does crop spraying, airplane maintenance and stuff. I was talking to him and the guys at the shop who also do maintenance who said they were having a lot of issues with the cables and who told me it would sure be nice if we could convert to straps. Our newer hangar building already has liftstraps and autolatches on its 11 doors."

Tom Wenker, the Sauk Centre Municipal Airport Fixed Base Operator (FBO) concurred with these issues.

"We've been working on airplanes for 30 years and have known about Schweiss Doors as most airports have at least one of your doors around somewhere. We were having issues with the cables fraying and with the pulleys on the door. The doors now open faster and definitely smoother. Just the fact that we are not dealing with failure issues is the biggest thing and there is a much larger safety margin," noted Wenker.

“ We've been working on airplanes for 30 years and have known about Schweiss Doors as most airports have at least one of your doors around somewhere. We were having issues with the cables fraying and with the pulleys on the door. The doors now open faster and definitely smoother. Just the fact that we are not dealing with failure issues is the biggest thing and there is a much larger safety margin. ”

- Tom Wenker, FBO

Sauk Centre Municipal Airport

Sauk Centre, Minnesota

His next step was to see if it was feasible to upgrade to a liftstrap system. A call to Schweiss Doors answered that question and put the operation in motion.

Complete liftstrap conversions were done on three hangar doors that are 43 ft. x 12 ft. clear; three 39.6 ft. x 12 ft. clear and the remaining five doors that are 41.6 ft. x 12 ft. clear.

"The strap doors are safer. With the old cable system, if you would lose a cable one half of the door would shift and get stuck. If a strap would break - we haven't had that issue at all - the door will continue work fine and safely. The other side of it is lack of maintenance. We probably put new cables on two doors each year. This eliminates all that time and maintenance out there which is helpful for us," noted Clink.

The liftstrap conversion and installation went well and was done by two Schweiss factory door installers.

Much to the delight of pilots and the airport maintenance crew, this 43 ft. x 12 ft. 22-year-old bifold hangar door now lifts faster and smoother with new motors and liftstraps that replaced the outdated cable-lift system.

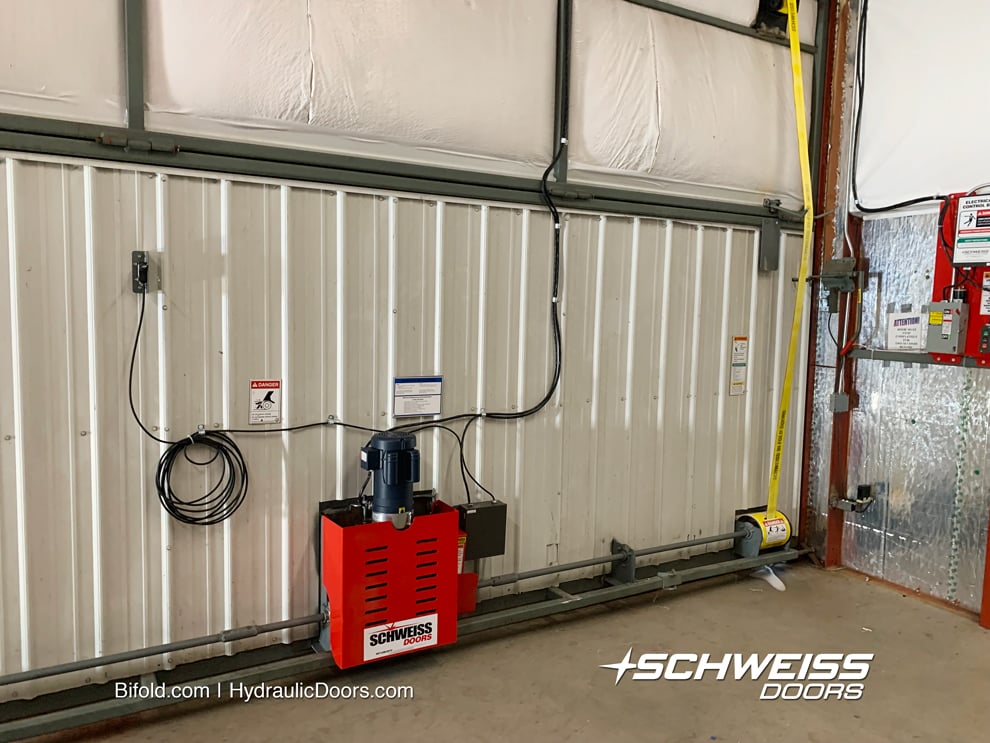

Control panels for the bifold doors are situated at eye level. The manual latch system can be seen to the left of it.

Sauk Centre Municipal Airport

Sauk Centre Municipal Airport is approximately three miles southeast of downtown Sauk Centre on Stearns County Highway 186. It has two runways, one runs NW-SE, which is 3300' x 75' with hard bituminous surface. The other is E-W, which is 2270' x 130' with a grass surface which is marked with yellow cones. The airport has two hangars that house 11 planes each and an arrival and departure building with a courtesy vehicle available.

Both runways are lighted from dusk until dawn and self-service fuel is available 24 hours a day with a credit card. Central Planes Aviation, a private airplane maintenance service facility operates from another hangar.

Services provided include: Aviation fuel, aircraft parking (ramp or tiedown), hangar rental / courtesy car (free for pilots to use in the local area), a pilots lounge / snooze room, public telephone, computerized weather and restrooms.

Sauk Centre Municipal Airport is located at 39115 County Road 186, Sauk Centre, Minn. For inquiries pertaining to the city airport, call the Central Planes Aviation Maintenance Building at 320-352-3013 or City Hall at 320-352-2203. saukcentre.govoffice2.com

Go onto the next article . . .

PJ Helicopters converts three

bifold cable doors to liftstraps

Three Schweiss Doors liftstrap conversions on bifold cable doors by other manufacturers were completed on two PJ Helicopters doors that are 56 ft. wide and another that is 60 ft. wide. They varied in height from 18 ft. to 22 ft. PJ Helicopters headquarters facility is located at the Red Bluff Municipal Airport about 130 miles north of Sacramento, California. (Photo by Dillin Mendenhall)

When you've got millions of dollars' worth of helicopters and fixed-wing aircraft that require moving in and out of your hangar's multiple times day and night; for the sake of convenience and all-around peace of mind, you want zero maintenance hangar doors that are safe and reliable.

“Cables were just a maintenance nightmare. We were having a lot of problems keeping the cables adjusted and replacing broken cables. It was really hard to tell when a cable was slipping, and it would go from looking perfectly fine to fraying almost immediately. We have millions and millions of dollars in aircraft rolling underneath these doors so we have to be incredibly careful, if one of those doors came down the aircraft would be totaled - maintenance has dropped off to nothing with the liftstraps.”

- Dillin Mendenhall, Rigging Mgr.

PJ Helicopters, Red Bluff, California

PJ Helicopters, based out of the Red Bluff Municipal Airport two miles south of Red Bluff, California is no fly-by-night operation, although they do make night flights. They are the only night vision utility service in the United States using the Bell 407 helicopter equipped with the most recent night vision goggle technology.

Their history goes back slightly over 51 years ago as a helicopter operation that started with a great-uncle of the family, Samuel Pierpont Langley; the aviation pioneer and scientist for whom Langley Air Force Base in Hampton, Virginia is named. Langley was used during World War I as a flying field, balloon station, observers' school, photography school, experimental engineering department, and for aerial coast defense.

In the earliest year's, PJ Helicopters was a small agriculture spraying business starting with two pilots and two airplanes. Thirty-four helicopters now fill four of its hangars along with another four fixed-wing aircraft that are flown by its 25 pilots and an operation employing 110 individuals.

Three of its bifold hangar doors were equipped with cable-operated doors about 20 years ago, and in recent years these doors by another manufacturer were a maintenance headache.

“Schweiss is the door of choice. We did three strap replacements on Hangar 1 and one more at another PJ Helicopters hangar. I did additional strap retrofits for another gentleman at the Red Bluff Airport at the same time for a total of seven liftstrap conversions there. The newest maintenance facility hangar has Schweiss hydraulic doors. Straps are so much better than the cable operation, I don't know why anyone would want a cable door.”

- Andy Wood, President

North Valley Building Systems

Chico, California

"Between utilities, inspections, fires and our paint booth hangar, I would say we make thousands of calls on an annual basis. Just today, we have 15 helicopters out and about," said PJ Helicopters Rigging Manager Dillin Mendenhall. "That means our doors open and close constantly, especially in the winter or when the weather is bad. One hangar bay is shared with a paint booth, so it isn't opened as much, maybe twice a day, but the others are opened about 30 times a day or sometimes left open during nice weather."

The decision to convert from cables to liftstraps was easy to make.

"Cables were just a maintenance nightmare. We were having a lot of problems keeping the cables adjusted and replacing broken cables. It was really hard to tell when a cable was slipping, and it would go from looking perfectly fine to fraying almost immediately. We have millions and millions of dollars in aircraft rolling underneath these doors so we have to be incredibly careful, if one of those doors came down the aircraft would be totaled - maintenance has dropped off to nothing with the liftstraps," noted Mendenhall.

"Liftstraps make the doors easier to look over for potential problems. They are certainly a lot less maintenance, not as much adjustment, you don't have to worry about cable clamps slipping or even the fact that when they started fraying people could rub against them," said Mendenhall.

PJ Helicopters are constantly on the move making thousands of calls on an annual basis. That means their doors open and close constantly; especially in the winter when the weather is bad. Replacing broken cables was a maintenance nightmare that constantly required them to be adjusted. (Photo by Dillin Mendenhall)

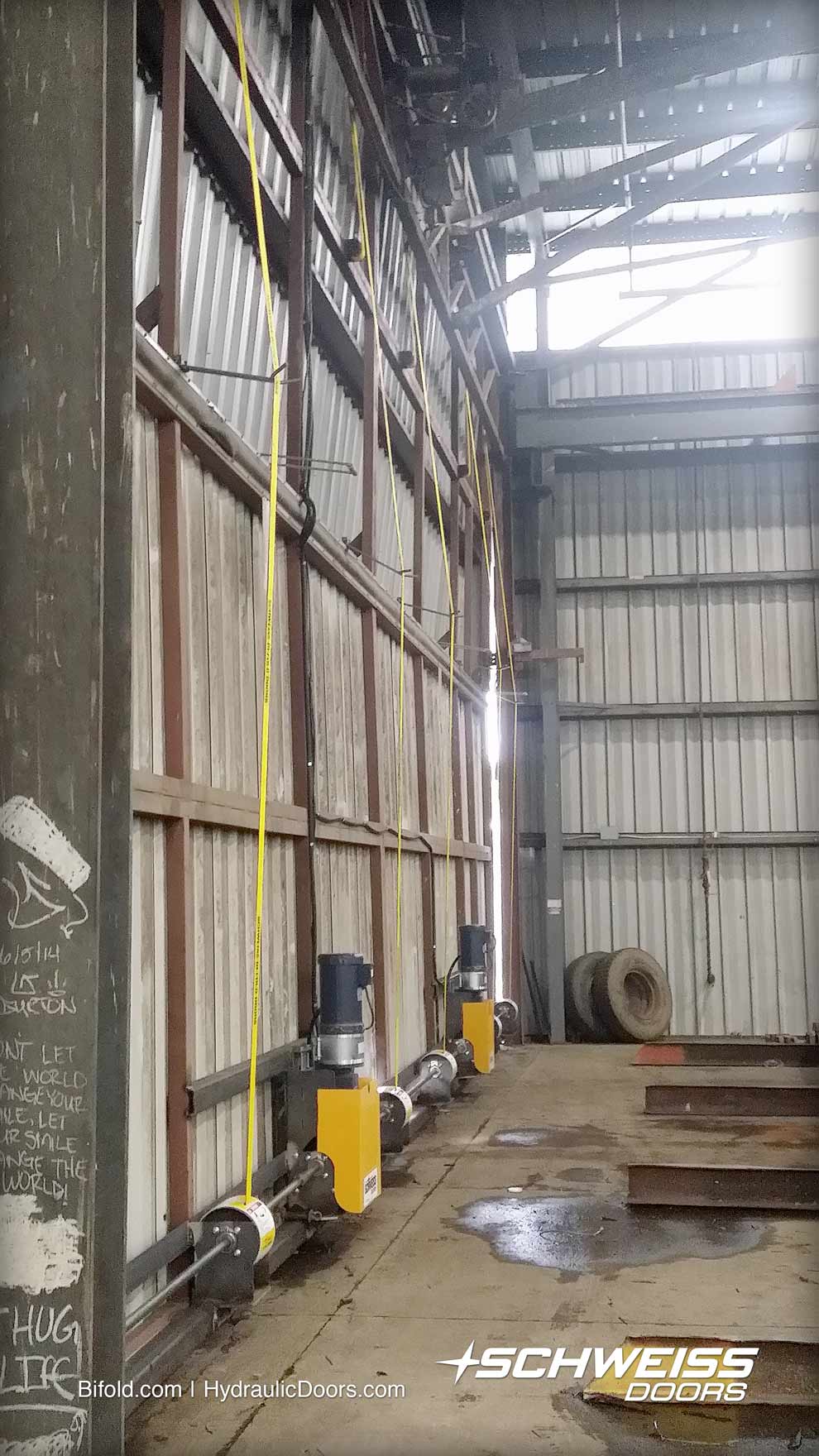

North Valley Building Systems of Chico, Calif. arranged to retrofit three Schweiss Doors liftstrap conversions on PJ Helicopters bifold cable doors. These doors, all from other manufacturers, included two that are 56' wide and another that is 60' wide. They varied in height from 18' to 22.' The doors have automatic latching systems.

"Schweiss is the door of choice. We did three strap replacements on Hangar 1 and one more at another PJ Helicopters hangar. We did additional strap retrofits for another gentleman at the Red Bluff Airport at the same time for a total of seven liftstrap conversions there," said Andy Wood, President of North Valley Building Systems. "Straps are so much better than the cable operation, I don't know why anyone would want a cable door. We were already working with Schweiss on the other hydraulic doors. The newest maintenance facility hangar has Schweiss hydraulic doors," added Wood.

Wood said he likes the Schweiss bifold liftstrap door system with its bottom drive motors and door gearing system because it makes maintenance so much easier than other brands of bifold doors that have top drive motors that require you to climb up high on the door.

PJ Helicopters, Inc.

The family history of this precision helicopter operation started with a great-uncle of the family, Samuel Pierpont Langley, the aviation pioneer and scientist for whom Langley Air Force Base is named.

PJ Helicopters originated as a small agriculture spraying business starting with two pilots and two airplanes. This was the beginning of a new chapter in their company's already very storied history. It is a 51-year family-owned world class precision helicopter lift service serving all industries nationwide since 1971. Since then, PJ Helicopters has steadily grown by implementing more operations to their resume; such as powerline work, pipeline support, construction and external loads, firefighting, law enforcement, US Forest Service contracts and more.

Their facility covers 30,000 square feet with 34-plus helicopters, in Red Bluff, California including a 7,000-square-foot truck shop that provides gas and maintenance services to their helicopters. Their current fleet includes the following models: UH-60A Utility Hawk, Bell 214B, Bell UH-1H 703 Plus, Bell 429, Bell 407, MD 530F, MD 520N, and a Bell 206L-3. Their fixed-wing fleet includes a Pilatus PC-12, Cessna Grand Caravan EX, Cessna 17 and a Beechcraft Bonanza.

“Between utilities, inspections, fires and our paint booth hangar, I would say we make thousands of calls on an annual basis. Just today, we have 15 helicopters out and about. That means our doors open and close constantly; especially in the winter or when the weather is bad. One hangar bay is shared with a paint booth, so it isn't opened as much, maybe twice a day, but the others are opened about 30 times a day or left open during nice weather.”

- Dillin Mendenhall, Rigging Mgr.

PJ Helicopters, Red Bluff, California

PJ's intensive helicopter lift and safety training program has contributed to PJ Helicopter's excellent service and safety record. Over the years, PJ Helicopters has maintained a flawless safety record. Their professional technicians are factory trained A&P Mechanics who provide top-level maintenance. All maintenance is done in-house by factory trained personnel. Any helicopter can be dispatched with maintenance and ground crews as needed. All classes, types of rigging and support equipment are available.

PJ Helicopters and its subsidiaries are proud to support both domestic and international customers. With multiple operating locations throughout California, they are happy to respond to any emergency or create a customized estimate for your project anytime, anywhere.

PJ Helicopters also works with C.A.M.P (Campaign Against Marijuana Planting) working with agents from the DOJ, CHP, USFS, National Guard and other law enforcement agencies around the state eradicating marijuana on public, private and federal lands.

As a leader in delivering cargo, data as well as people on time and on budget, they also provide services in a variety of the following industries:

Utility - Aerial Survey, Surveillance and Control, Pole Setting and Wire Stringing. Construction - Long Line Cargo, Concrete Transport, HVAC Units, Precise Bolted Steel Connections. Water Diversion - Movement/Placement of Shoring Materials. Law Enforcement - Search/Rescue, Surveillance. Agriculture - Seeding, Fertilizing, Frost Control, Crop Management. Forestry - Fire Control, Controlled Burning, Planting, Rehabilitation. Air Taxi - Aerial Photography, Commercial Charter, Private Transportation, Transporting crew to remote locations. Remote Landings - High Altitude, Snow Landings.

PJ Helicopters is located at 903 Langley Way, Red Bluff, CA. Phone: (530) 527-5059 http://www.pjhelicopters.com

North Valley Building Systems of Chico, California built this 300 ft. x 100 ft. PJ Helicopter hangar and converted three cable doors to Schweiss bifold strap doors. PJ Helicopters has one other hangar with a hydraulic door all of which hold their fleet of 34 helicopters and four fixed wing aircraft for 25 pilots. (Photo by North Valley Building Systems)

“Liftstraps make the doors easier to look over for potential problems. They are certainly a lot less maintenance, not as much adjustment, you don't have to worry about cable clamps slipping or even the fact that when they started fraying people could rub against them.”

- Dillin Mendenhall, Rigging Mgr.

PJ Helicopters, Red Bluff, California

North Valley Building Systems, Inc.

North Valley Building Systems has been an integral part of the community for over 15 years. Their President, Andrew J. Wood, has over 40 years of experience in construction and design, and their qualified staff has over 125 years of combined experience. Their dedication to work has always been focused on providing the best quality and performance for its customers.

Working with a project architect, they provide quality construction services-from building permits, to site development and construction, to final landscaping. As a General Contractor, they work with your building team and utilize the most skilled trades and safe site conditions to keep your project running on time.

Their quality steel building systems offer extensive versatility through wide-open interiors and a variety of bay sizes, eave heights, roof slopes and almost any type of exterior you choose. Whatever you're looking for, you're sure to find the perfect fit for your facility as well as your budget.

By hiring North Valley Building Systems for your construction management services, you'll receive cost efficiency, quality control and representation of your best interests. They manage complex on-site activity to ensure cooperation among the entire Design-Build team and meet critical schedules and budgets. Construction management brings professional expertise and knowledge to bear directly on your project to streamline the construction process.

Other services include: Site Inspection including zoning requirements, detailed estimates, design and engineering, on and off-site work, foundations and flatwork, pre-engineered metal buildings, tilt-up concrete buildings, exterior and interior finishes, mechanical and electrical and landscaping.

North Valley Building Systems was named four times as Butler Builder of the Year (Western Region) and four times High Volume Builder of the Year (Western Region), 2000 Self-Storage Builder of the Year and 2015 Classic II Builder of the Year.

They are located at 30 Seville Ct, Chico, CA. Phone: (530) 345-7296.

www.northvalleybuilding.com

Liftstraps on what were cable-lift doors from two other companies, now make these hangar doors, up to 60 ft. in width, much safer, quieter and quicker to open and close. (Photo by Dillin Mendenhall)

California has some beautiful sunsets and sunrises as seen here looking out the hangar door. PJ Helicopters is a leader in delivering cargo and services for law enforcement, agriculture, utility and construction work in addition to air taxi and charter trips for individuals. (Photo by PJ Mechanic, Chris Matt)

Go onto the next article . . .

Vero Beach, Florida airport packed up

its hangar cable troubles with 14 bifold

liftstrap door conversions

There's a marching song made popular during World War I whose lyrics begin with . . . "Pack up your troubles in your old kit-bag . . . And smile, smile, smile!"

“The City of Vero Beach was really, really happy with the whole 14 hangar door setup and how it went down. Schweiss has a better designed and cleaner operating system. By the third hangar we had a system set up to where we had all the structural components ready and our own welders and electricians ready to hook things up. We worked through all the small issues of adapting Schweiss equipment to an existing hangar door. We had great support from Jeremy at Schweiss Doors. By the time we were on our sixth hangar door we were a moving machine where everybody knew what they had to do. I would definitely recommend Schweiss doors and strap conversions to others.”

- Jim Lavold, Contractor

James S. Lavold, Inc.

Jupiter, Florida

In retrospect, that's sort of what Jim Lavold, co-owner of James S. Lavold, Inc. did when his family-owned general contracting company completed 14 Schweiss Door liftstrap conversions on lease and rental Box and T-Hangars for the Florida city-owned Vero Beach Regional Airport. Now the city and aircraft owners are smiling, smiling, smiling because these 20-year-old cable-lift doors no longer pose a safety hazard and lift faster and much more efficiently.

"As an approved contractor for the FAA we do a lot of airport work and renovations. We also work on local government-owned and private hangars, hurricane repairs and things like that. We travel all over the country and work in all states. We did a project for the FAA renovating control towers in Hilo, Hawaii, St. Thomas, St. Croix and Puerto Rico," said Lavold.

Lavold's general construction business is located in Jupiter, Florida, about an hour's drive south of the southeastern coast city of Vero Beach. It's a place where you can experience beautiful beaches, luxury amenities and an easygoing lifestyle.

"We picked up on this Vero Beach project because it was something we specialize in anyway. There were other structural parts to this hangar project other than the strap conversions," said Lovold. "Vero Beach wanted the Schweiss conversion kits for their existing 50 ft. wide x 20 ft. high steel doors originally manufactured by, antiquated to say the least, Wilson Doors who are no longer in business. They had trouble with cables busting. On one occasion a cable snapped, and a door came down and hit one of the planes.

Lavold said the pilots are a lot more at ease with the strap systems modernized with automatic latch systems. He got to know a lot of the tenants and they were really excited about this city project that actually got through funding and worked out.

The City of Vero Beach approved the liftstrap conversion as part of its Airport Master Plan that projected a vibrant airport to meet the needs of the entire region. The electrical control boxes for the liftstrap doors were mounted just to the right of the bifold walk doors.

"The City of Vero Beach was really, really happy with the whole 14 hangar door setup and how it went down. Now the airport operations people who have taken over maintenance on these doors have said, 'There's nothing left for us to do - everything works great.' We had an independent on-site engineering inspection team that wrote me a nice letter commending us on how we took care of everything," said Lavold.

Once the Lavold team got working on the installation of the liftstrap conversion they breezed right through it.

"Schweiss has a better designed and cleaner operating system. At first, we had a learning curve on how to get through installing it. By the third hangar we had a system set up to where we had all the structural components ready and our own welders and electricians ready to hook things up," noted Lavold. "We worked through all the small issues of adapting Schweiss equipment to an existing hangar door. We had great support from Jeremy at Schweiss Doors. By the time we were on our sixth hangar door we were a moving machine where everybody knew what they had to do.

"I would definitely recommend Schweiss doors and strap conversions to others. We are actively seeking out new projects starting in Florida, but we will go anywhere. The City of Vero Beach still has two box hangars with bifolds on them that they want to switch over when they get approved for funding," added Lavold.

Go onto the next article . . .

Low maintenance was the factor

behind Colorado strap conversion

“I was very impressed with the development, design and smooth, well-engineered operating design of the doors and motors. Our end-user knows that the door is operating well and is secured well with the straps. Schweiss Doors also has the technical expertise that helped make the strap conversion go smoothly. Schweiss has a great track record and we know the quality of their system. Brent and their whole team at Schweiss were great to deal with. Schweiss is our go-to company for strap conversions.”

- Michael Pecora,

Senior Account Manager

Rocky Mountain Dock and Door

Littleton, Colorado

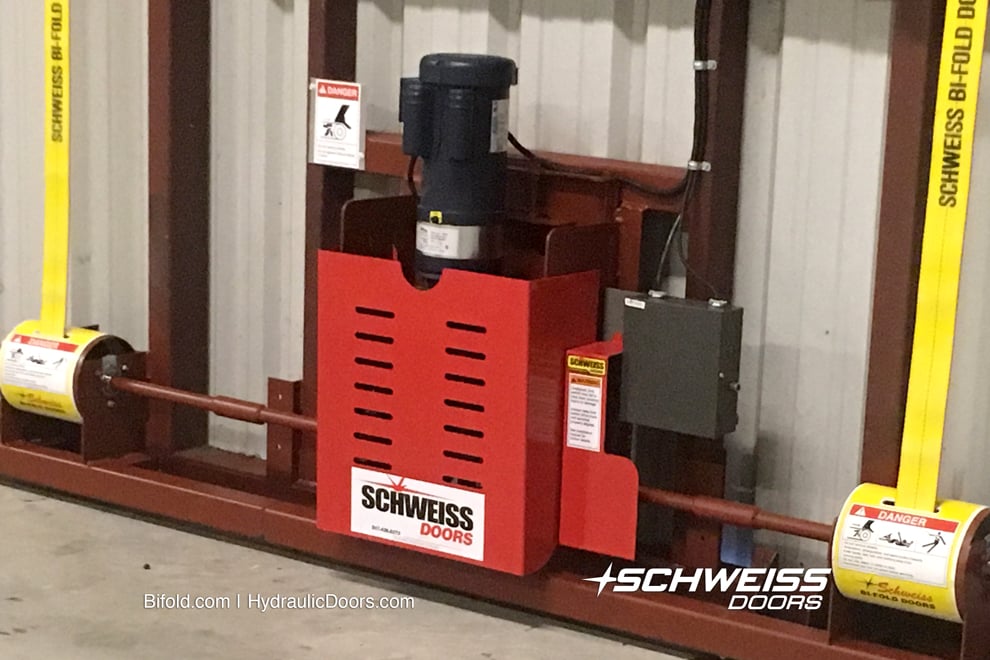

Four strong liftstraps powered by two Schweiss motors now lifts and lowers the bifold door smoother, faster and quietly. The company was having troubles with frayed cables that had to be replaced on several occasions.

After going through the hassle of replacing frayed bifold door cables a, manufacturing company in Denver, Colorado, along with their door partner, Rocky Mountain Dock and Door Specialties (RMDDS) decided it was time to contact Schweiss Doors for a liftstrap conversion on one of their 52' x 25' doors made by a different manufacturer.

Michael Pecora, a Senior Account Manager for RMDDS of Littleton, Colorado, stated; "This was the second Schweiss liftstrap conversion for this manufacturing company. We changed cables multiple times and it was time to do a strap conversion for them."

Pecora has been in the door industry for several years and has seen every type of door. He understands the quality Schweiss brings to any project.

"I was very impressed with the development, design and smooth, well-engineered operating design of the doors and motors," said Pecora. "Our end-user knows that the door is operating well and is secured well with the straps. Schweiss Doors also has the technical expertise that helped make the strap conversion go smoothly. Schweiss has a great track record and we know the quality of their system. Brent and their whole team at Schweiss were great to deal with. Schweiss is our go-to company for strap conversions."

Rocky Mountain Dock and Door Specialties

Rocky Mountain Dock and Door Specialties is a customer-focused door service company that can service or repair just about any door. They are a 30-year, locally owned and operated business that thinks and acts like business people, rather than a company that just fixes doors.

They understand that a broken door can directly impact your business, and the last thing they want is for a broken door to impact your business. Their company, now with approximately 20 employees offers 24-hour service, and was built as being one of the premier door subcontractors on significant construction projects in Colorado

Their areas of expertise are in commercial garage doors, entry doors, high-speed and specialty doors, as well as dock levelers and storefronts

Rocky Mountain Dock and Door is located in Littleton, Colorado. 303-797-3667. www.RMDockandDoor.com

The low-maintenance strap system will save the company time and expense. The exposed gear system on the door was made safer by placing safety shields on it.

Rocky Mountain Dock and Door said the technical expertise from Schweiss helped make the strap conversion go smoothly.

The Denver manufacturing company is pleased with the strap conversion and knows that the bifold door is operating well and is secured well to the building with liftstraps when shut.

Go onto the next article . . .

No more hearing the 'Pop and Crack' of cables . . .

New Georgia hangar door gets 'royal'

uplift with Schweiss liftstrap conversion

Georgia Crown Distributing Company leases a virtually new 80' x 100' hangar at the LaGrange Callaway Airport that went through a royal uplift with a Schweiss bifold liftstrap door conversion even though the cables from the other manufacturers door weren't even rusted or frayed yet.

Corporate pilot, Chuck Newman, a pilot of 23 years and with a background in construction, didn't like the door supplied by another manufacturer, not in the least bit.

“We've had cable doors in the past and I know how difficult it is to keep cables changed out. It seemed like we would get three or four years out of a cable and then they would start to fray and they are difficult to adjust. The door we had was a lower end door so the shaft diameter was pretty small and there were a lot of things about it I didn't like. The door with straps is now unbelievably quiet. We were always hearing the cables pop and crack. This door is now almost perfectly silent. It actually basically turned into a Schweiss door in every respect except for the framework itself.”

- Chuck Newman, Pilot

Chief Pilot / Aviation Dept. Mgr.

Georgia Crown Distributing Co.

"It was definitely my idea to do a straplift conversion," said Newman. "We had originally spec'd the hangar for a Schweiss door, and then they showed up with this other door. I wasn't a fan of it, and it had only been in service for about three months. This (conversion) was the easiest way to beef it up and make it last the life of the hangar."

You might think this would have been a hard sell for corporate approval, but Newman said he wouldn't accept it any other way and would have rather sent the door back, but they didn't want to do that.

"We've had cable doors in the past and I know how difficult it is to keep cables changed out. It seemed like we would get three or four years out of a cable and then they would start to fray and they are difficult to adjust; not something I wanted to deal with. The door we had was a lower end door so the shaft diameter was pretty small and there were a lot of things about it I didn't like. While doing the strap conversion we redid the drive shaft, so that beefed it up. I also didn't like the overcentering mechanism that it had - it had a chintzy little winch device that locked the centers down; was really hard to deal with. When they did the strap conversion they did the automatic centerlock system as well. The Schweiss automatic latch system replaced a very manual system prior to this."

Ten strong liftstraps, each capable of lifting 29,000 lbs. now lift the door faster, smoothly, safely and quietly. A remote opening system gives the pilot the option to open the door from the cockpit of the plane.

It actually basically turned into a Schweiss door in every respect except for the framework itself," noted Newman.

Danny Hutchinson, Superintendent at Astra Construction Services in Woodstock, Georgia, placed the order for the conversion on the 70' x 18' jet hangar door and noted that the process of replacing the cables went very well. Hutchinson said Newman, who ran the hangar for Crown Royal, just wanted Schweiss liftstraps on it to replace the cables on this other manufacturers door as a maintenance and upgrade. The door is also equipped with a remote opener.

"The liftstrap conversion directions were good, but we also followed a YouTube video that showed how to install the conversion. We were doing some stuff off and on; one man probably worked on it for a day and a half with a little help here and there. The hangar belongs to the Troup County Airport Authority and leased to the Crown Royal distributors. It's a nice looking system that works fine and has an automatic locking system," said Hutchinson.

LaGrange Callaway Airport Director of Maintenance, Larry Nommensen, said the pilot, Chuck Newman, had seen Schweiss straps on other hangars that he deals with. He said the straps look very nice, work well and run smooth.

The corporate hangar, that houses a Learjet 75, has many amenities such as a kitchenette, two offices, Schwank radiant heaters and a maintenance shop.

Newman said he became familiar with the strap conversion after talking to Mike Schweiss at the Oshkosh, Wisconsin airshow and also at the National Business Aviation Association Convention held in Las Vegas. He also looked at another hangar at the LaGrange Airport that had a Schweiss strap conversion.

“The liftstrap conversion directions were good, but we also followed a YouTube video that showed how to install the conversion. We were doing some stuff off and on; one man probably worked on it for a day and a half with a little help here and there. It's a nice looking system that works fine and has an automatic locking system.”

- Danny Hutchinson, Superintendent

Astra Construction Services, Woodstock, Georgia

"The door with straps is now unbelievably quiet. We were always hearing the cables pop and crack. This door is now almost perfectly silent," said Newman.

Astra Construction Services

Astra is a full service general contractor with the expertise to deliver a wide variety of construction projects throughout the State of North Carolina. Their experience and knowledge in infrastructure, building renovation, new construction and recreational facilities makes them the premier provider for all your construction needs. Their skilled and dedicated team will provide exceptional service on every project.

Astra is the largest builder of parks and recreation facilities in the Southeast. Their experience in building the spaces that bring communities together is unmatched in the industry. Work on groundbreaking urban projects like the Atlanta Beltline have solidified their reputation as the go-to builder for creating spaces that enhance communities.

Astra builds structures that turn heads. Their knowledge in vertical construction and commitment to building something they are proud to call their own has made its commercial construction well recognized for its superior quality and efficient methods. They offer multiple avenues for completing projects, including simple job order contracting options.

In addition to being a licensed general contractor, they are also a licensed utility contractor with a team that specializes in earthwork, utility installation and grading.

Astra's Corporate Office is located at 300 Churchill Ct, Woodstock, GA. Ph. (770) 992-9300. They also have an office at 5960 Fairview Road, Suite 300, Charlotte, NC. www.astragroupinc.com

The 80' x 100' hangar with its 70' wide bifold door gives more than adequate room for the Learjet 75. With a door this big Newman wanted to upgrade it with strong, reliable liftstraps for maintenance-free operation.

LaGrange Callaway Airport

The LaGrange Callaway Airport is located 50 miles Southwest of Atlanta, Georgia in Troup County. It is positioned to service the needs of general and business aviation users.

Their FBO provides many benefits to its customers such as competitive Phillips 66 AvGas & Pre-mixed Jet Fuel prices and T-Hangers. There is an Aircraft Maintenance Facility provided by Southside Aviation, located in the hangar on the west side of the FBO. Aircraft rental and flying instruction is provided by the flying club and Airventures.

LaGrange Callaway Airport has two runways including an Instrument runway (5,600 feet) with three types of approaches: ILS, VOR, and GPS. Since they are located just outside Atlanta's Class B airspace, they have no congestion or ATC delays. With excellent year round weather, they have 300 VFR flying days each year. They are also the host airfield for the local Civil Air Patrol Squadron (GA-153).

Their excellent location is convenient for pilots living from Peachtree City, GA to Auburn, AL. In addition, it is very convenient for cross-country fuel stops for flights enroute to Atlanta or Columbus, GA.

The well-insulated bifold door has a Schweiss automatic latch system that locks it and pulls it in weathertight to the hangar.

The electrical control box is mounted just to the right of the door for easy access. The door can also be opened, closed or stopped at any level with a remote opening system.

Go onto the next article . . .

Loenbro Flight Department pilot has strap

conversion done for his peace of mind

When pilot Mark Haakenson's employer at the Loenbro Flight Department purchased a hangar at the Great Falls International Airport in Montana all it took was a quick look at the frayed cables on the 55'x15' door made by another manufacturer to convince him that something needed to be done.

"My first experience with Schweiss Doors was back in Willmar, Minnesota where I was working as a contract pilot. An employer of mine had built a hangar with, I believe, an AeroLift door - it was a brand new hangar with brand new doors. AeroLift came out eight or nine times and couldn't get the door rigged up right. I was working in the hangar and one of the Schweiss technicians was on the field doing some work on somebody else's hangar. I went over and chatted with him and asked him if he could take a look at our door. Well, it only took him a half hour and he had it working great. We had a Schweiss technician rigging an AeroLift door and he did a better job than AeroLift did," chuckled Haakenson.

He said the next time he had anything to say about hangar doors or lift systems, he was always pointing toward Schweiss. Going forward, Haakenson moved out to Great Falls seven years ago where he worked for a company flying their Beech jet. Their hangar had a cable door on it that Haakenson said had no identification on it to tell him who it was made by - it wasn't a Schweiss door.

“When my current company purchased this hangar from the old owners one of the things I told them was they needed to calculate the expense of replacing the cables and pulleys with a liftstrap system from Schweiss. I told them I wouldn't tug an airplane in under that door in the shape it was - the cables had been replaced two years earlier and they were fraying enough that you would catch them on your coat as you walked by. In a month or two we had ordered the liftstrap system with the straplatch option as well. I love it; I've got people that come in here that want to see how the straplatch system works because I keep on bragging on it. It's a great system, the door goes up faster, it's quiet and more secure; the old door had three 3/8th" cables, now I have five nylon straps so I feel a lot better walking under the door.”

- Mark Haakenson, pilot

Loenbro Flight Department

Great Falls, Montana

"While I was here we replaced the cables once. When my current company purchased this hangar from the old owners one of the things I told them was they needed to calculate the expense of replacing the cables and pulleys with a liftstrap system from Schweiss," said Haakenson. "I told them I wouldn't tug an airplane in under that door in the shape it was - the cables had been replaced two years earlier and they were fraying enough that you would catch them on your coat as you walked by.

"In a month or two we had ordered the liftstrap system with the straplatch option as well. I love it; I've got people that come in here that want to see how the straplatch system works because I keep on bragging on it. It's a great system, the door goes up faster, it's quiet and more secure; the old door had three 3/8th" cables, now I have five nylon straps so I feel a lot better walking under the door."

At first Haakenson said he was going to hire a contractor to install the liftstrap system with automatic latches and a remote opener. He called Schweiss Doors and asked how hard it would be to do the conversion; they convinced him to give it a try. His oil and gas company has a ton of welders, so he showed his project managers what he wanted to do. They put it together with no problem at all.

"I think the biggest thing I like about the door now is the sense of security; it lets me know the door is safe. The other is the convenience of the remote and the strap latch; it's fantastic. Every other hangar that I've used you had to go through this process of trying to get the door latched properly. Now I just have the remote in my pocket and it's a done deal, it's slick," noted Haakenson.

Haakenson said his hangar door gets used two or three times a week. He flies a Cessna Citation V, a turbofan-powered small-to-medium-sized business jet.

Pilot Mark Haakenson gives the thumbs up to liftstrap conversion. Frayed cables on the existing 55'x15' door made by another manufacturer convinced him that something needed to be done before the door came crashing down on him or on the company's Cessna Citation V.

Loenbro

Loenbro, an oil and gas pipeline company, has the expertise and resources to deliver exceptional services to its customers across the United States. They provide a single-source solution for companies needing construction, electrical, industrial, mechanical and inspection work performed on their next project.

From its early days working in a refinery in Great Falls, Montana, they now have operations in 20 states and experience in several industry sectors. They design, build, install, service, maintain and repair heavy industrial infrastructure and facilities no matter the size.

Founded in 1998 by Paul and Jon Leach, Loenbro began as a small team of welders focusing predominantly on refinery projects throughout Montana. As their reputation for quality work expanded, so did the company, allowing them to explore the many new and emerging areas within our industry.

Along with many challenging projects, Loenbro has built a stellar reputation for providing comprehensive services. As they've grown, they've developed capabilities to provide solutions to wide range of industries - from mining and oil and gas to manufacturing, pharmaceuticals and beyond.

Loenbro is a leader in pipeline construction and installation in Montana, Wyoming and the Dakotas. Their ASME/API certified welders are experts in the installation of gathering systems for oil and gas exploration, refinery systems process and utility piping as well as the following applications of energy, chemical, agricultural, DOT pipeline, plant maintenance, shutdowns, turnarounds and outages.

Loenbro has also continued to invest time and resources in the best tools, latest technologies, and also in training its team to ensure that they consistently deliver the best products and services available anywhere.

Today, Loenbro offers a variety of services, including plant maintenance, phased array inspection, HDPE fusion, exotic materials welding, heat-treating, pipeline construction, industrial insulation and more. Our team now includes more than 300 of the best welders and industry professionals available anywhere, and together they continue to look for new opportunities to even better meet the changing needs of their clients.

Loenbro is located at 1900 32nd Ave NE, Black Eagle, Montana. (406) 453-1542. www.loenbro.com

The bifold door, made by an unknown manufacturer, now has five liftstraps, an automatic latch system and remote opener. The hangar gets opened two or three times a week.

The cables on this door, prior to the liftstrap conversion, had just been replaced two years earlier and were already fraying. He now says the door opens faster, quieter and locks securely.

Go onto the next article . . .

Reliability was key factor for hangar

door owner to convert to liftstraps

If you were to put the justification in one word for why Dave Frederikson of Eau Claire, Wisconsin decided to retrofit his 60' x 20' cable lift hangar door to the Schweiss liftstraps and autolatch system, that word would be "safety."

“I've always been impressed with the straps and always have been concerned about the safety of a cable versus a strap. I finally got the wherewithal to do it. Other than my cable system was 20 years old, I didn't like it and I didn't want to put in a new door to replace this other manufacturers door. Now that the door is up, I believe it has to be much safer because I have eight straps holding it up rather than six cables. I have to believe even if I have a failure of three or four straps that the door would still hold up. The straps are easy, they don't look ratty and the insulation isn't going to fall apart on the doors.”

- Dave Frederikson

Eau Claire, Wisconsin

"I've always been impressed with the straps and always have been concerned about the safety of a cable versus a strap. I finally got the wherewithal to do it," said Frederikson. "Other than my cable system was 20 years old, I didn't like it and I didn't want to put in a new door to replace this other manufacturers door. Now that the door is up, I believe it has to be much safer because I have eight straps holding it up rather than six cables. I have to believe even if I have a failure of three or four straps that the door would still hold up. The straps are four times stronger than a cable."

His introduction from the cable to liftstrap conversion system came via seeing Schweiss Doors displays at the Oshkosh, Wisconsin AirVenture Fly-In & Convention over several years. There was also a person he met there that got a new door from Schweiss. That, followed up with a visit to the Schweiss Doors website, convinced him to go with the conversion on his hangar door at the Chippewa Valley Regional Airport.

Frederikson said he had no problem following the easy-to-install very well done directions that came with the conversion kit. He used a local welder to put in additional bracing and to weld the gearboxes and bulk heads to the existing door. He said the whole process took about a week to cut the old stuff off and get it operational. He also said he very much appreciated the help he got from Schweiss Doors employees, Jeremy Rieke and Neal Brooks, in the ordering and parts departments.

"I think they are faster than a cable door, just looking at it, it seems more secure and safer. The physical appearance of it is well engineered. I know that by having put it on myself it is durable, it weighs a lot and mechanically it's quieter. I have two gearboxes instead of one smaller unit from the original door. It certainly is smoother and I have a lot more trust in it. All-in-all it's worked out well."

Frederikson said his door already had an automatic latch system with locking arms on it. With a little modification he was able to keep using the same arms and said doing the conversion wasn't difficult by any stretch To dress up the appearance of the interior of the door Frederikson put the new Schweiss interlocking insulation panels on the door.

"I've always appreciated the engineering of the straps. I think they are going to prove to be a welcome addition. The straps are easy, they don't look ratty and the insulation isn't going to fall apart on the doors," added Frederikson.

This is how his bifold door, purchased from another manufacturer, looked prior to the conversion. In addition to the cable to liftstrap conversion, Frederikson removed his fiberglass insulation and replaced it with the new Schweiss interlocking insulation panels to give the door a new clean look.

Chippewa Valley Airport, Wisconsin

Chippewa Valley Regional Airport is a public use airport in Chippewa County, Wisconsin. The airport is owned by Eau Claire County and is located three nautical miles north of the central business district of the city of Eau Claire.

It is the largest airport in the 30-county northern Wisconsin area and serves primarily the Chippewa Valley region, operating on a budget approved by a commission equally representing the interests of Chippewa, Eau Claire and Dunn counties.

The airport is mainly used for general aviation and business travel; the Eau Claire-based Menards Corporation uses CVRA to base their fleet of aircraft to serve their stores throughout the Midwest. It is occasionally used as an alternative-landing site for flights bound for Minneapolis-Saint Paul International Airport.

Chippewa Valley Regional Airport covers an area of 1,100 acres at an elevation of 913 feet above mean sea level. It has two runways: 4/22 is 8,101 by 150 feet with a concrete surface and 14/32 is 5,000 by 100 feet with an asphalt/concrete surface.

For the 12-month period ending December 31, 2015, the airport had 22,549 aircraft operations, an average of 62 per day: 87 percent general aviation, 12 percent air taxi, less than 1 percent military and less than 1 percent scheduled commercial. In October 2017, there were 87 aircraft based at this airport: 60 single-engine, 10 multi-engine, 15 jet and 2 helicopters.

Hangar 54 Grill offers a diverse menu with many locally-sourced, made-from-scratch items with a full service bar overlooking the runway. Private meeting room space is also available.

It is included in the Federal Aviation Administration (FAA) National Plan of Integrated Airport Systems for 2017-2021, in which it is categorized as a non-hub primary commercial service facility.

Having the cables removed and the conversion completed, Frederikson has peace of mind knowing that straps are much stronger than cables.