“Look For Quality, Look For Price, You'll Buy Schweiss”

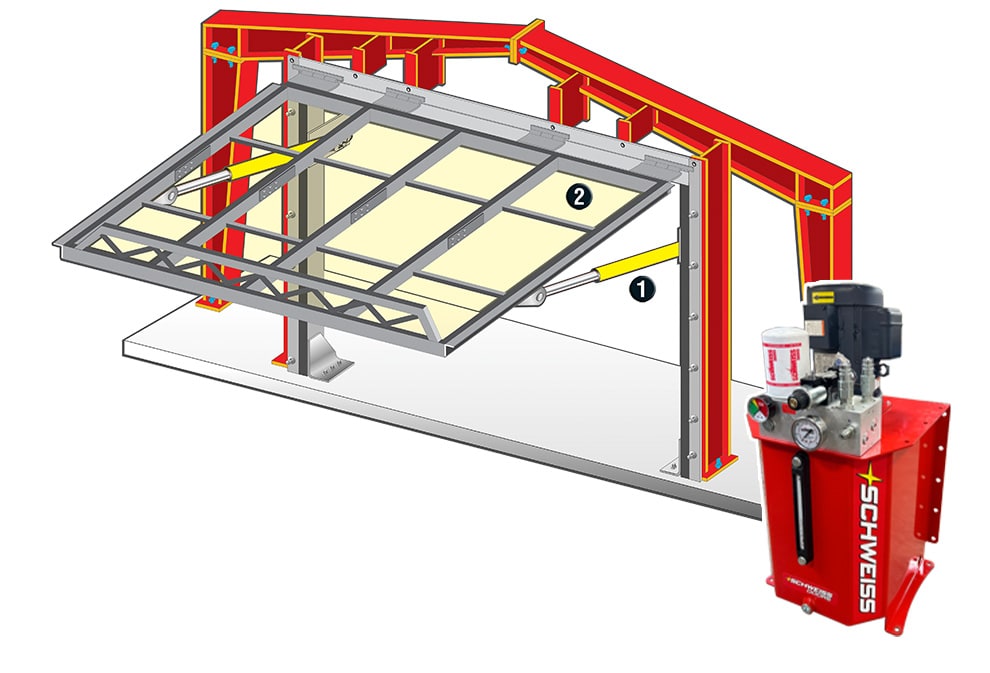

The Schweiss Red and Green Power manifold has a clean, crisp design. It features a polished finish, no exposed plumbing lines and a filter drainport that allows oil to drip back into the tank preventing messy oil puddles. Includes a filter clogging indicator showing when to change your filter element. 3000 PSI pressure gauge is standard and gives you the reading of the pump pressure used to open the door. Auxiliary screw-on oil filter is easy to change. Best quality filter that protects the hydraulic pump from impurities. Oil filter / breather cap / filler port has a rich looking polished finish. Clean looking! The easy screw-on cap has a built-in screen to keep debris out; important when adding oil. Sight glass displays the oil level and temperature in the oil reservoir tank. Red Power hydraulic oil reservoir has a heavy-duty, long-lasting powder-coated tank with a drain plug.

Schweiss Red and Green Power Hydraulic Pump Features:

Schweiss Doors has set new and higher standards in hydraulic pump development and safety features.

Schweiss Electrical System:

The Red and Green Power pump/motor system from Schweiss Doors offers superior electrical components that stand leagues above others. Why? Our Red or Green Power motors come equipped with a stand-alone electrical control box. The unique design of the Red and Green Power motor system is designed with safe UL listed components. Plus, it's composed of common components, standard in the electrical industry throughout the world. These electrical control boxes are also designed with ample space to safely house all required electrical components, such as contactors, transformers, relays, motor timers, rectifiers, and control fuses. Motor assemblies must be wired to National Electrical Code (NEC) standards.

Motors:

Schweiss Doors uses top-quality heavy-duty, brand name LEESON motors, totally enclosed, fan cooled, with a common 56C face mount standard shaft size, powering a single gear-driven pump. Plus, these quality continuous-duty motors are safety-backed with fuses and overload protection.

These Standard Features Come With Each Red

And Green Power Hydraulic Motor/Pump System:

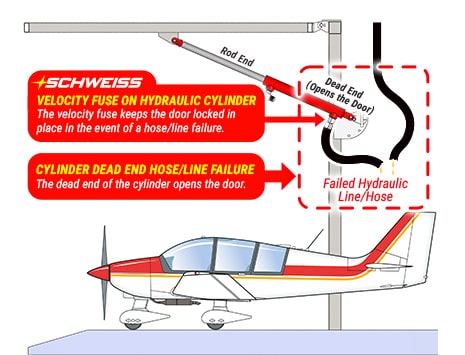

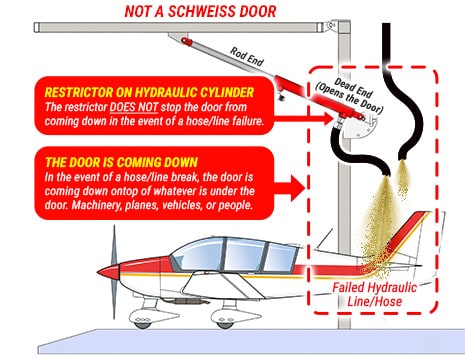

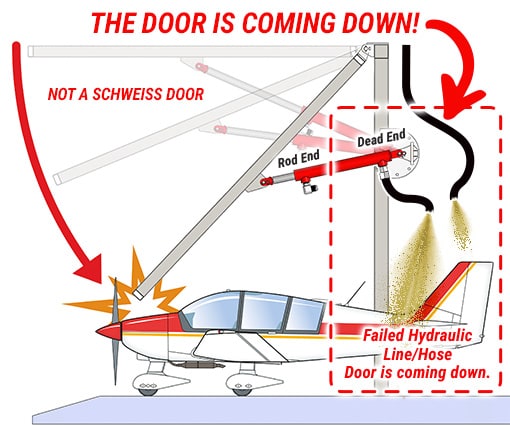

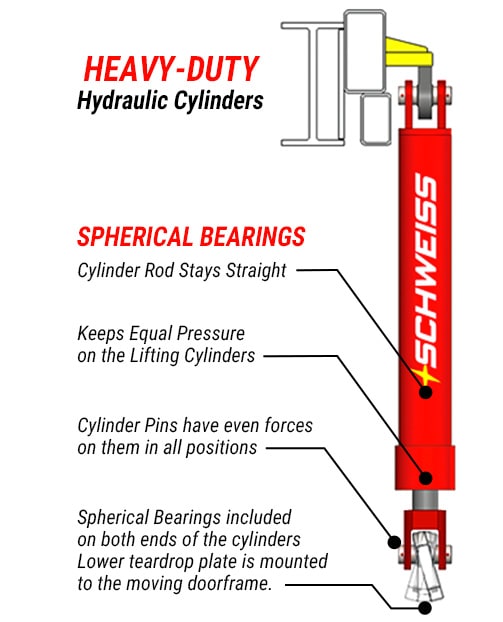

- Locks door up or down and holds the door safely in all positions.

- Locks and holds the door in the closed position... Never creeps open.

- The doors will lock up and hold if a hydraulic line bursts or leaks.

- Doors operate evenly in either direction.

- Allows you to safely lower door in an emergency from the ground level.

- Prevents thermal expansion in the cylinders. Releases excess pressure and oil back into the tank.

- Hydraulic directional control valve has a built in manual override in case the coil burns out. You can push the override on the valves to manually get the door to move in either direction.

- Low voltage control stations... only 24 volts DC, safer working with low voltage!

- Low voltage coils... lighted 24 volt DC coil connectors are safer to work around.

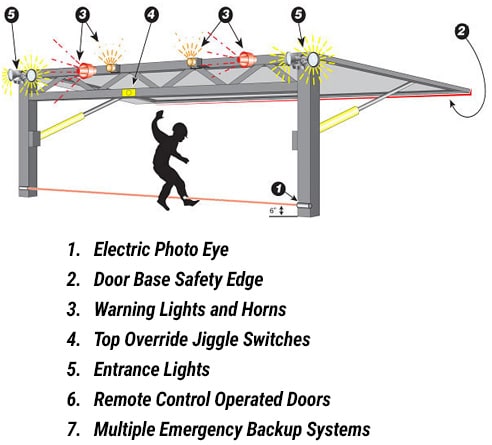

Standard back-up Systems Are On All Schweiss Hydraulic Doors:

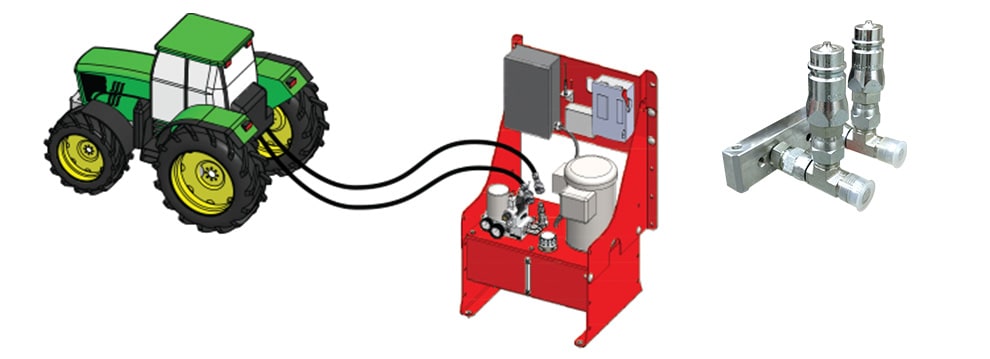

- Tractor fittings to raise or lower the door are standard on all Red Power hydraulic units from Schweiss.

Standard Emergency Lowering:

- Built in emergency lowering feature is standard on all Schweiss Doors. No tractor is needed in case of a power outage!

Optional DC Backup System:

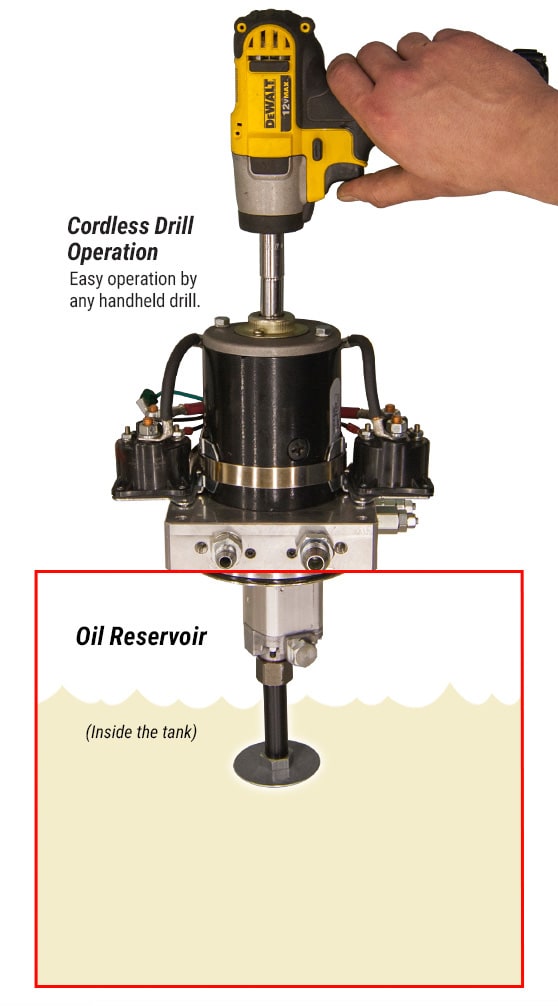

- DC backup - Includes battery operation and drill-driven back-up.

- Has its own auxiliary self-contained pump and motor!

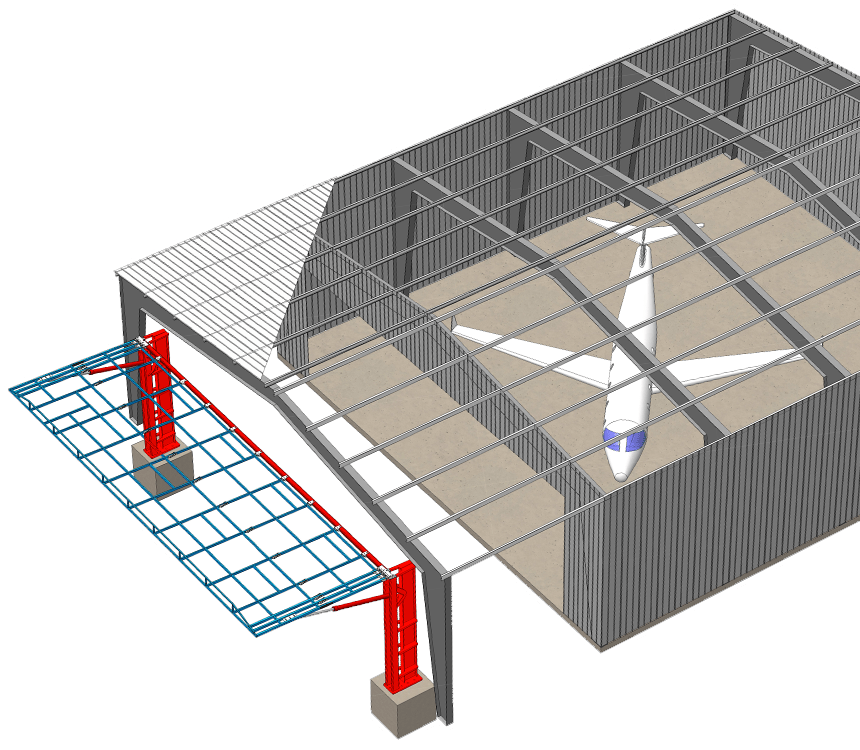

Multiple Mounting Styles

- Complete stand-alone hydraulic unit can be placed anywhere in the building.

- Hydraulic power unit can be placed under a workbench or anywhere in the room.

- Wall mount - mount anywhere away from the door opening or even in another room.

- With Schweiss you have options!

Remote Controls

- Remote controls can be easily added at any time!

Quality

Quality