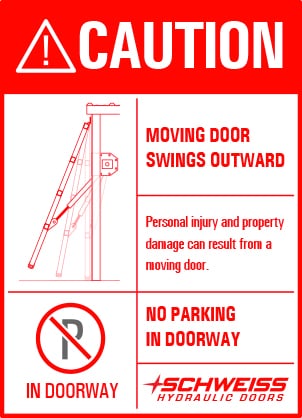

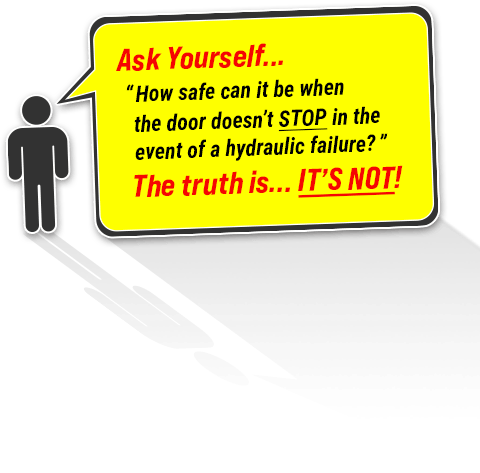

Warning

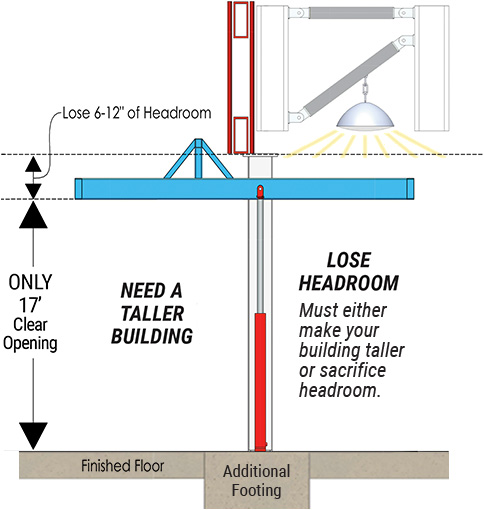

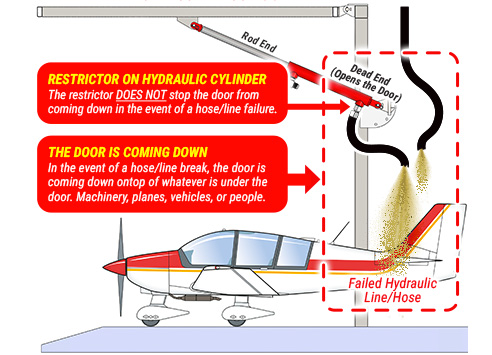

When others are using restrictors in the dead end of the cylinder as a safety device...

They may be setting you up for slow motion disaster, Your worst nightmare!

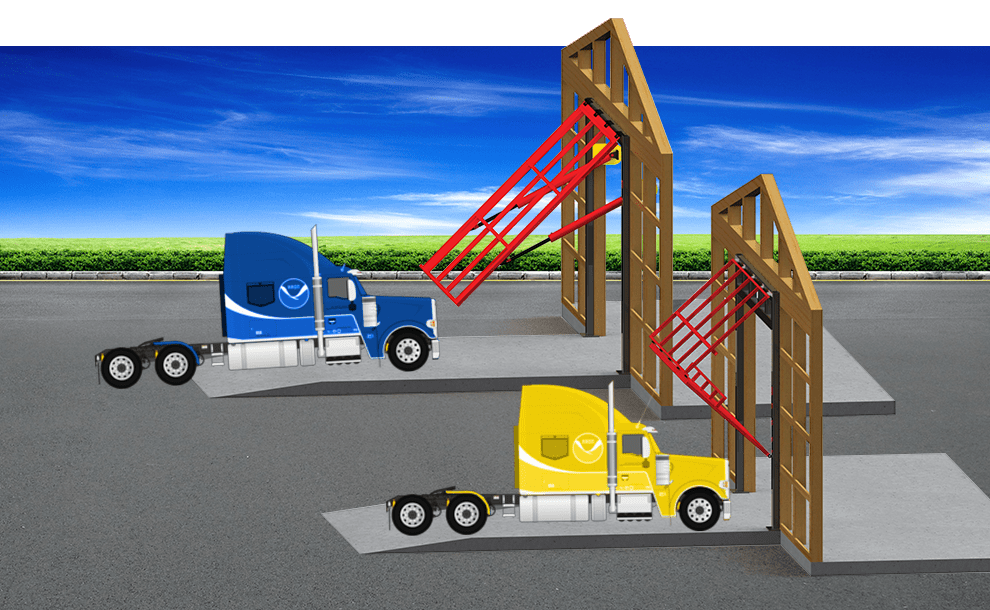

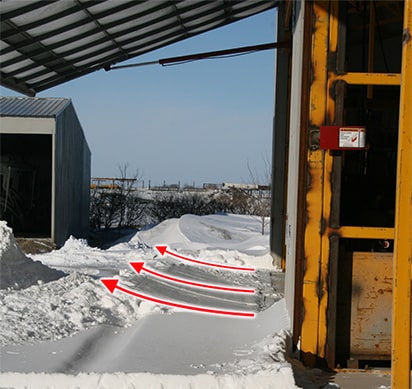

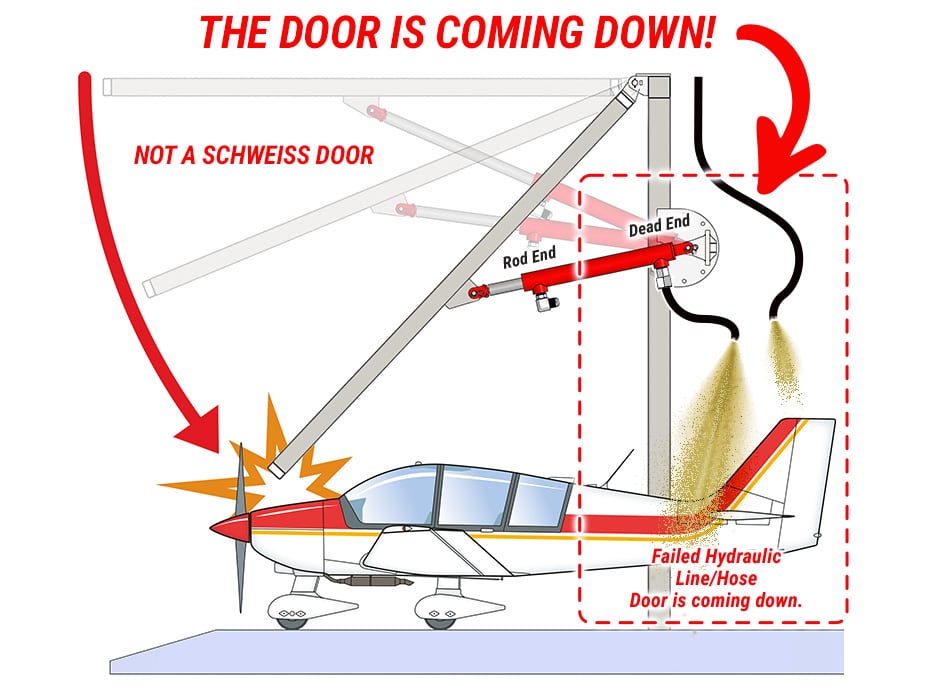

Worst Case Scenario...

To have a door come down on a million dollar plane or even worse than that, have the door come down on people and put lives at risk!

Be careful... when phrases like these are being used to explain what happens in the event of a hydraulic hose/line failure using restrictors.

“Gently coming all the way down...”

“Coasting down...”

“Controlled rate of descent...”

“Preventing the door from slamming down...”

Some Have Said:

“In the event of a hose or line breaking, it will not stop the door from falling. It takes 7 Seconds for a door to come down when a hose / line breaks.”

Fact Is... That's Not A Lot of Time!

The door is coming down with no safety built in to stop the door. Better Clear the area!

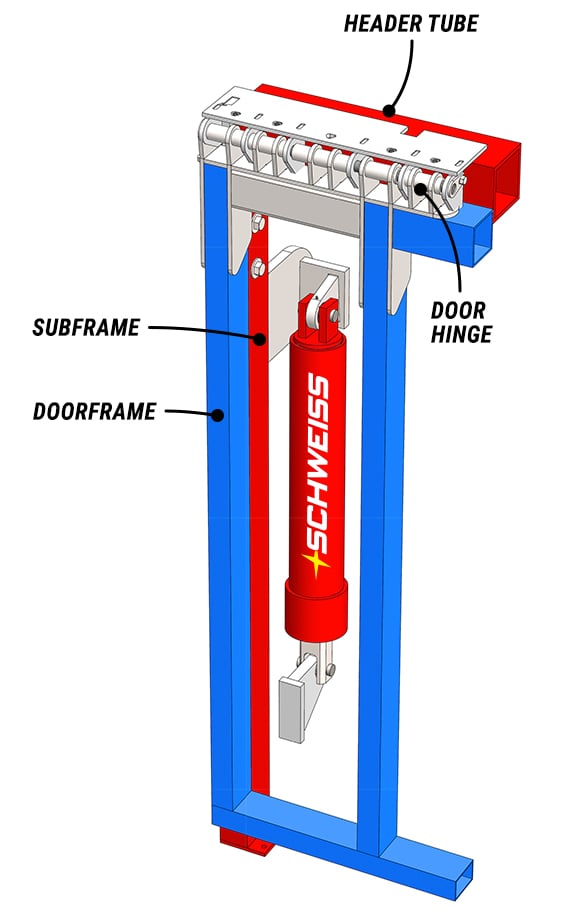

When manufacturers use Restrictors on their cylinders...

No safety built in.

Restrictors are not load holding.

The door will not stop if a hydraulic hose/line fails (on the dead end).

Door will come all the way down if there's a failure, no matter what.

The door is coming down on whatever is underneath it.

No way of stopping the door from coming down.

Slowing the door as it comes down isn't good enough.

Slow motion disaster... Your worst nightmare!

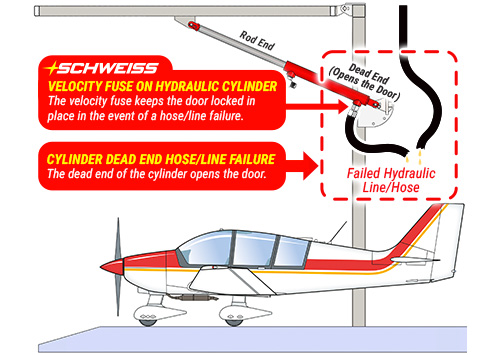

Did You Know?

If the manufacturer uses restrictors on the dead end of the cylinders, neither the restrictors or the photo eyes will stop the door.

You can't rely on the photo eyes to stop the door if a hose/line breaks on the dead end of the cylinder. The Door Is Coming Down...

Restrictors are not a safety device!

Find out what safety devices you're getting on the hydraulic cylinders when you order your hydraulic door.