WOOD BUILDING DETAILS

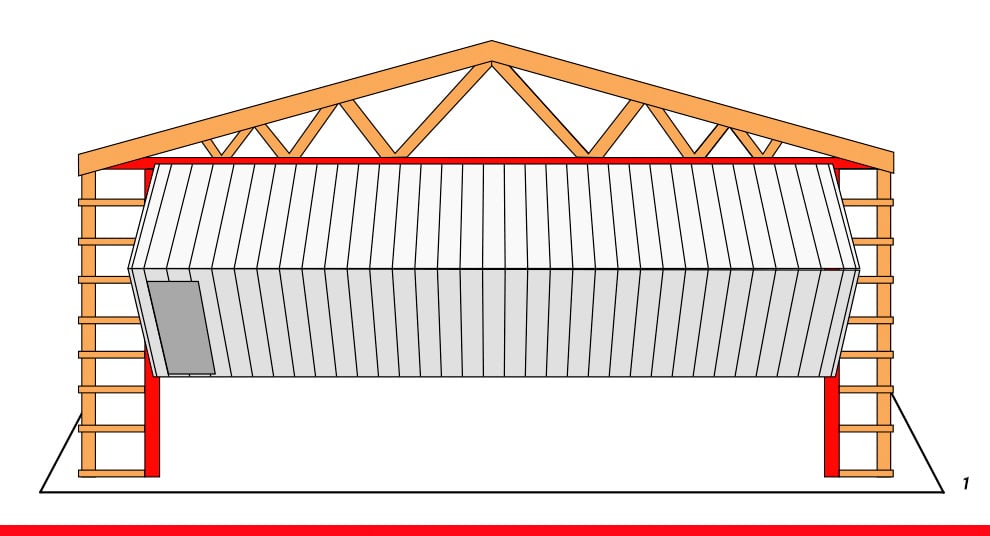

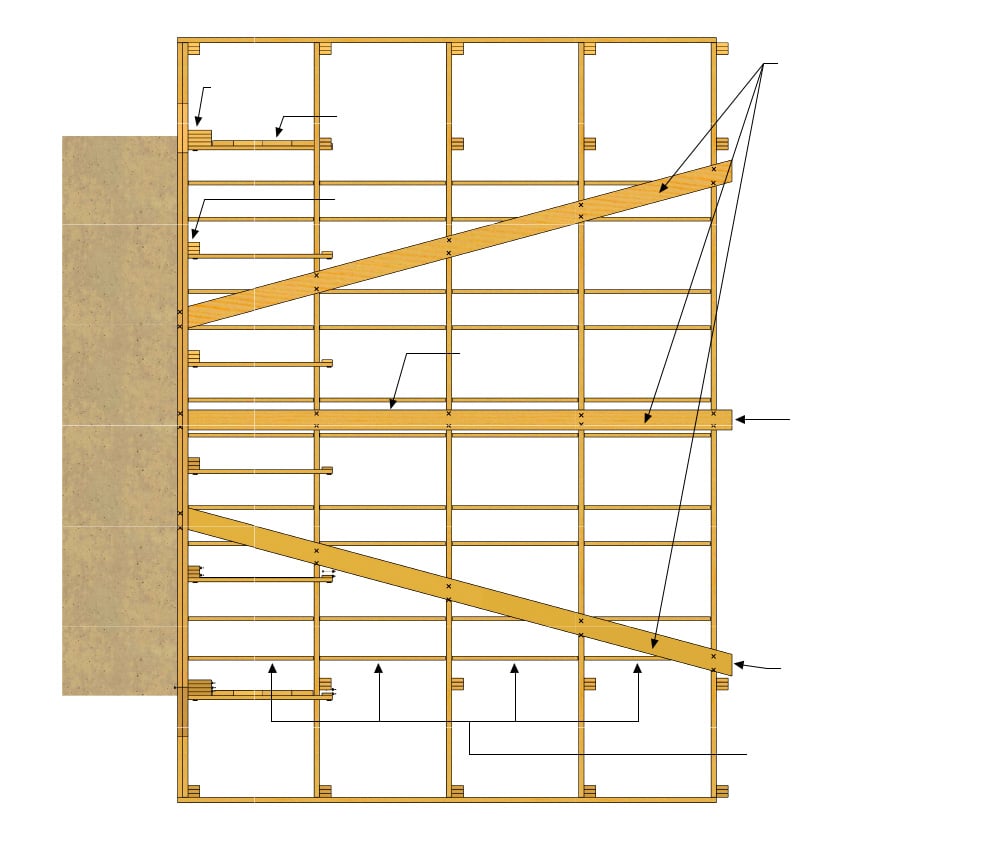

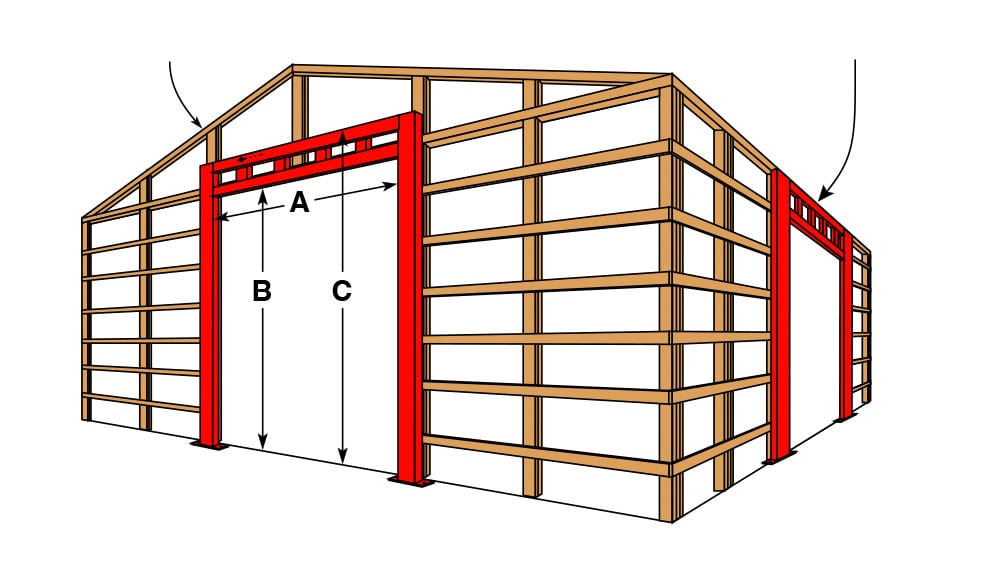

STANDARD HEADER BUILT INTO ENDWALL

- WOOD BUILDING (Style 1)

ENDWALL RAFTERS - HEADER PLACEMENTS

Modifying old or new buildings to accept a bifold door

Three 2x6's - Vertical Stiffener

ATTACH

DOOR HERE

Bolts

Built-in

Header Plate

Endwall Sheeting Above the

Bifold Doorframe & Hinges

Bolts

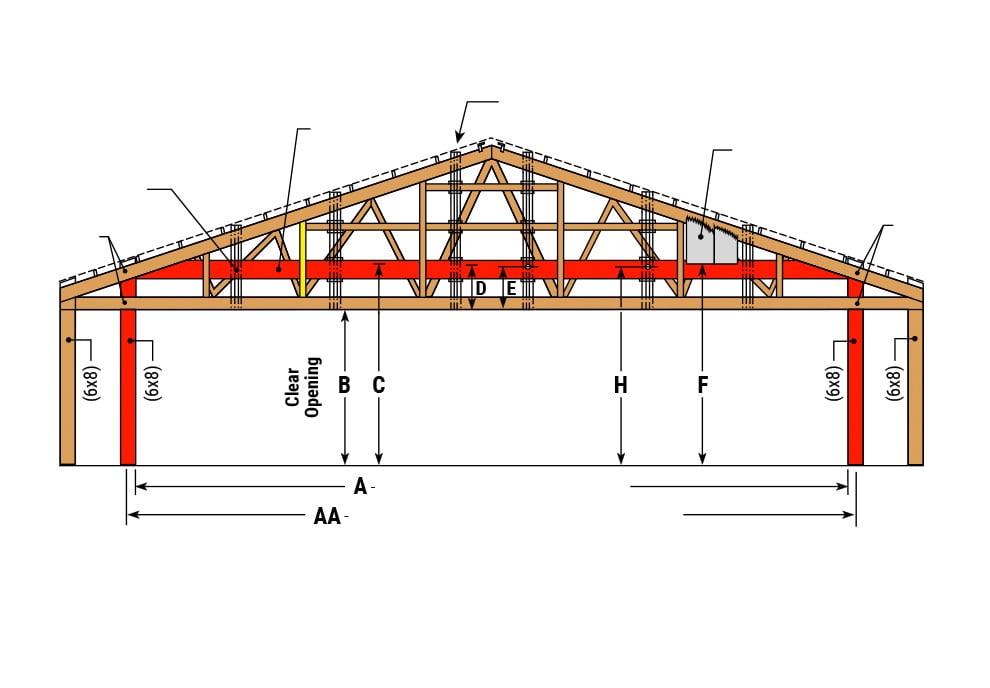

Clear Opening - Between Columns

Distance to keep the building sheet back

Shows where a header is installed in an endwall of a building.

The header is positioned up above the bottom of the rafter so you won't lose any headroom!

Open Endwall Rafters - Header Placements

We work with old or new buildings to make your Bifold Door work.

USING THE BOTTOM CORD AS HEADER

- WOOD BUILDING (Style 2)

Three 2x6's - Vertical Stiffener

Built-in Header Plate

ATTACH

DOOR HERE

Bolts

Endwall Sheeting Above the

Bifold Doorframe & Hinges

Bolts

Clear Opening - Between Columns

Distance to keep the building sheet back

Shows where a header is, using the bottom chord in an endwall of a building.

The engineered rafters can be doubled up for sufficient support.

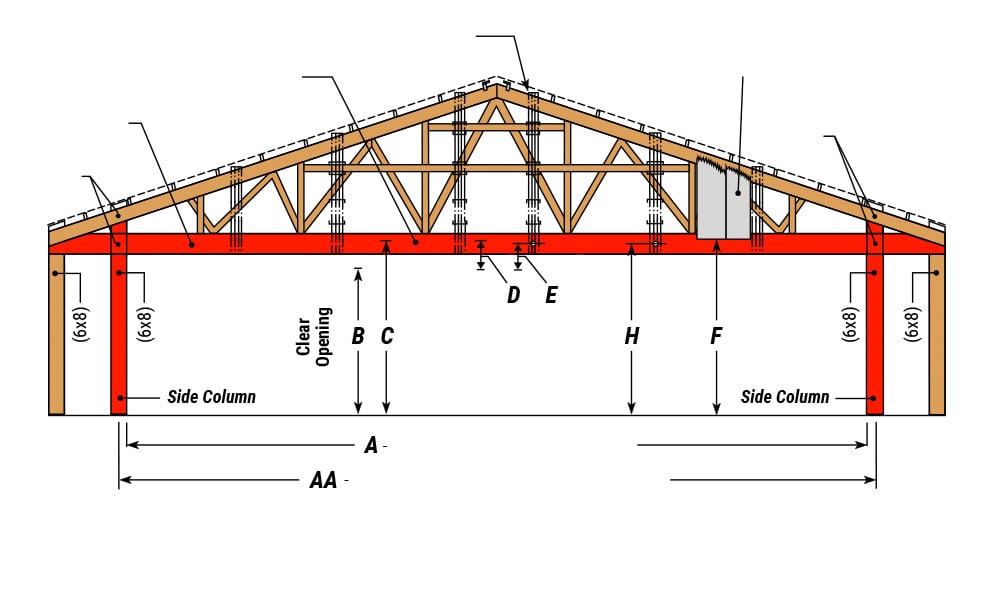

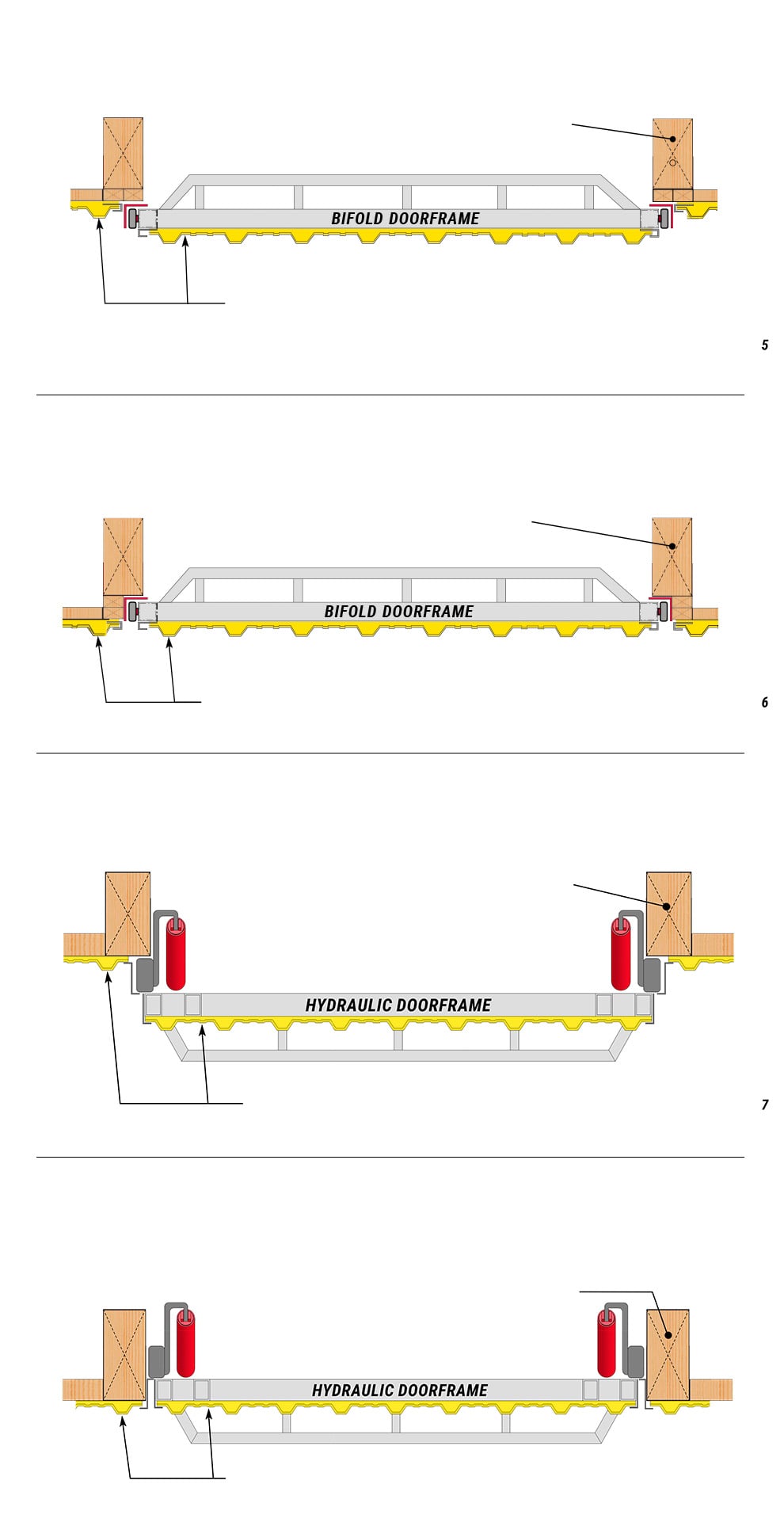

DOOR MOUNTING STYLES . . .

ON A WOOD BUILDING

BIFOLD . . . . FACE MOUNT

DOOR MOUNTED ON THE EXTERIOR WALLS OF BUILDING

Building side column

Sheeting is offset

Outside of building

BIFOLD DOORS OVERLAY THE SIDE COLUMNS ON THE FACE OF THE BUILDING

BIFOLD . . . . RECESSED MOUNT

DOOR MOUNTED ON THE EXTERIOR WALLS OF BUILDING

Building side column

Sheeting is on the same plane

Outside of building

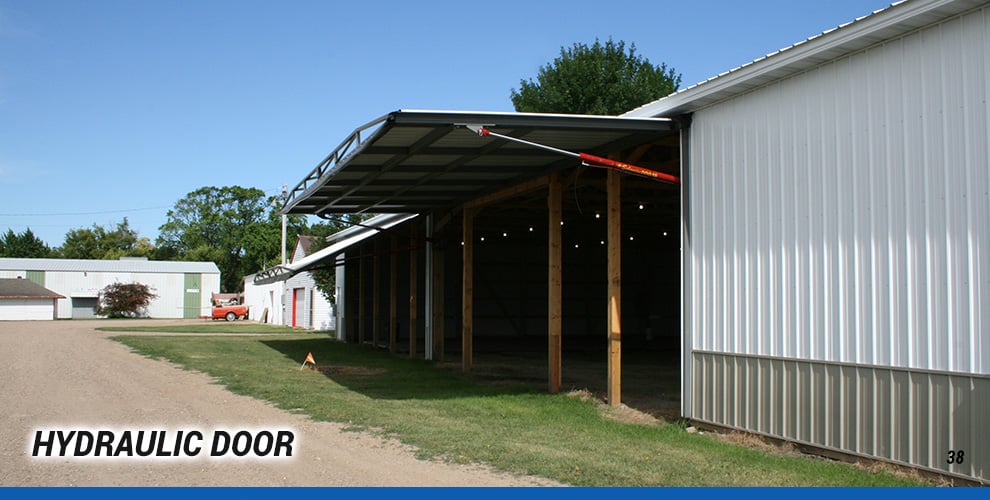

HYDRAULIC . . . . EXTERIOR / FACE MOUNT

DOOR MOUNTED ON THE EXTERIOR WALLS OF BUILDING

Building side column

Sheeting offset

Outside of building

HYDRAULIC . . . . RECESSED MOUNT

DOOR MOUNTED ON THE EXTERIOR WALLS OF BUILDING

Building side column

Sheeting is on the same plane

Outside of building

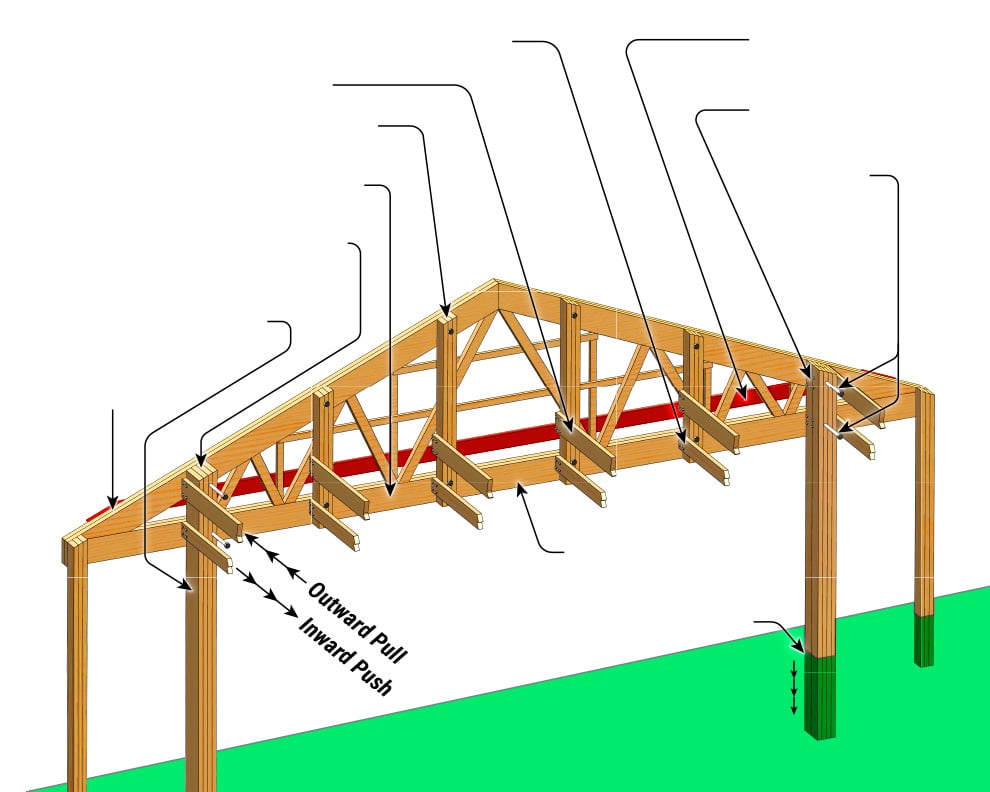

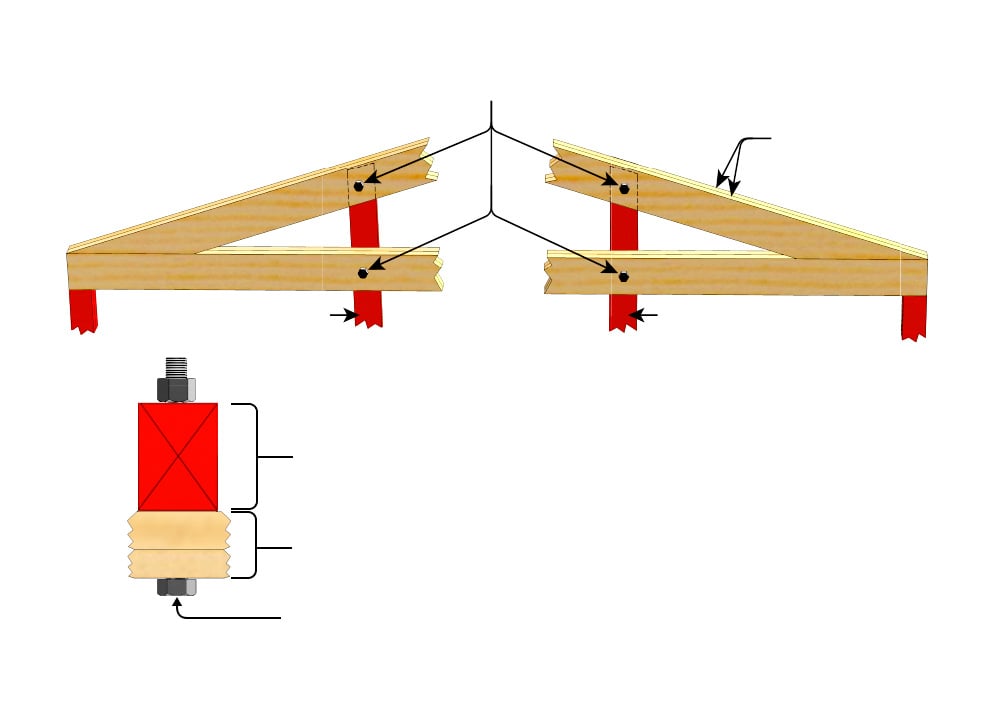

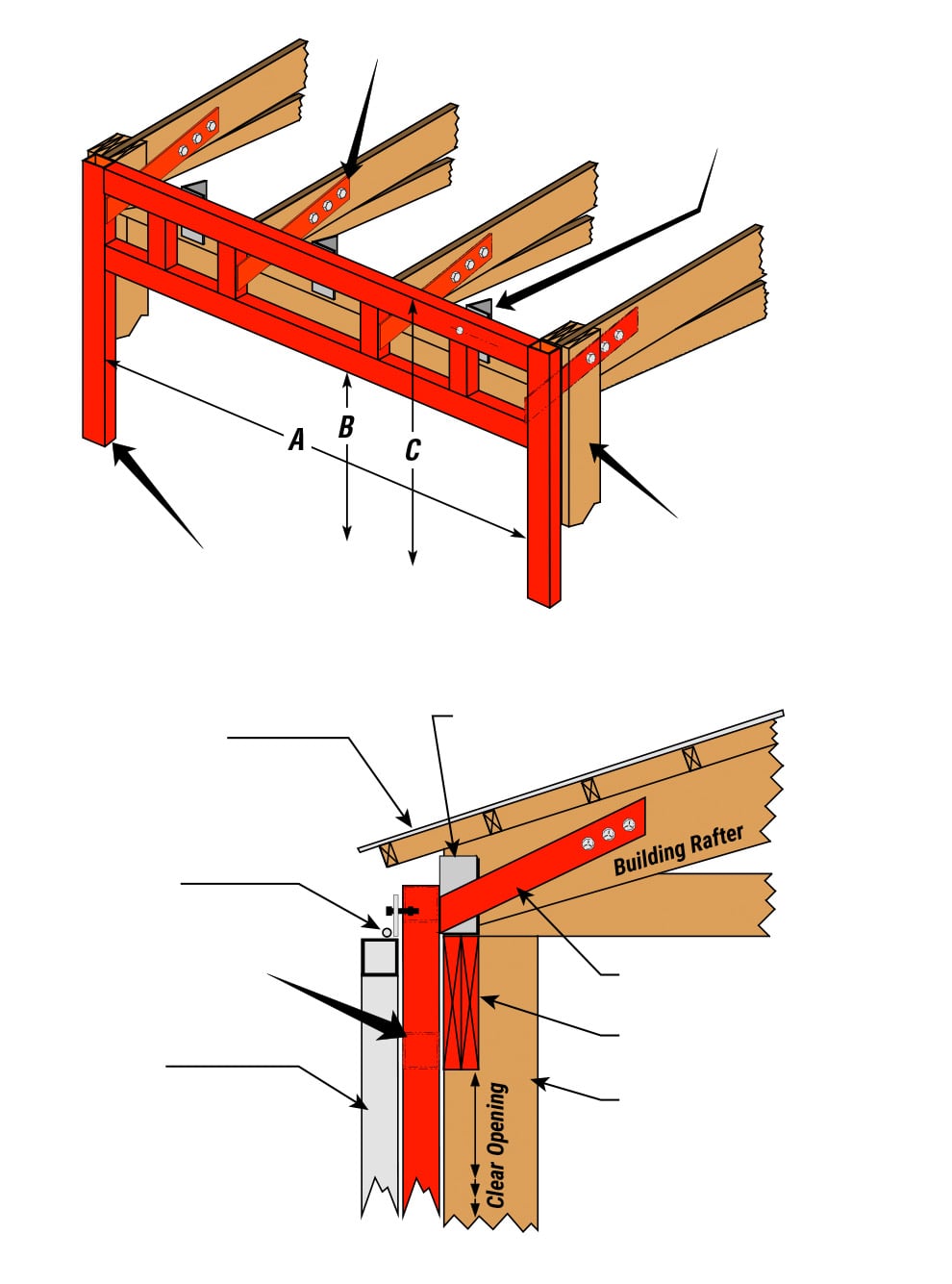

DOUBLE RAFTERS

. . . BACK TO BACK . . . WITH BACK BRACING (Style 1)

Put door header bolts through the vertical stiffeners

2 x 6's to tie back to next rafter

Triple - Vertical stiffeners - 2 x 6's by each

hinge location

Additional header plate or blocking

- For bifold only

Side Columns must be full length

On larger doors, double the side

columns and go deeper

Double rafters

back to back

Header built into the endwall

Columns must be full length

Bolt rafter to

the columns

This bottom cord must not

bow outward

Go beyond frost level

ENDWALL COLUMN BRACING

(WOOD BUILDING)

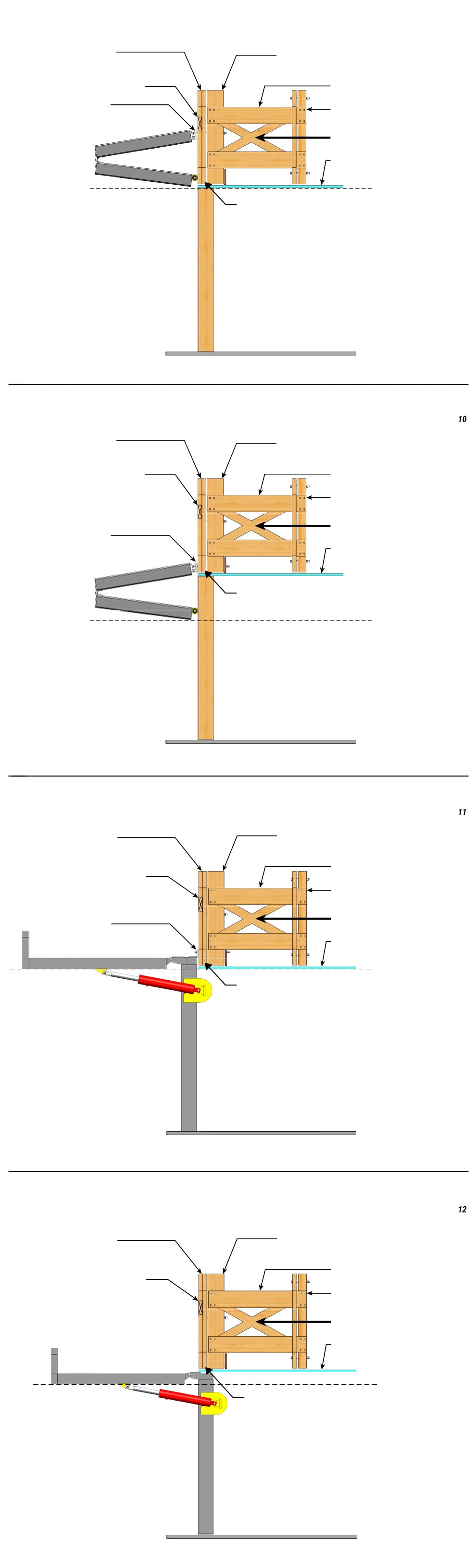

BIFOLD MOUNTED ABOVE HEADER . . . LOSE NO HEADROOM

2 x 6 Vertical

Need a backer plate to apply

building sheeting to

Header bolt

Vertical stiffeners - 2 x 6's

by each hinge location

Tie back brace

2 x 6 Vertical

X-BRACING

Ceiling

BIFOLD

Bottom of Header

SAMPLE OF

DOOR COLUMN

BRACING DETAIL

BIFOLD MOUNTED BELOW HEADER

2 x 6 Vertical

Need a backer plate to apply

building sheeting to

Header bolt

Vertical stiffeners - 2 x 6's

by each hinge location

Tie back brace

2 x 6 Vertical

X-BRACING

Ceiling

BIFOLD

Bottom of Header

SAMPLE OF

DOOR COLUMN

BRACING DETAIL

HYDRAULIC EXTERNAL MOUNT . . . LOSE NO HEADROOM

2 x 6 Vertical

Need a backer plate to apply

building sheeting to

Header bolt

Vertical stiffeners - 2 x 6's

by each hinge location

Tie back brace

2 x 6 Vertical

X-BRACING

Ceiling

HYDRAULIC

Bottom of Header

SAMPLE OF

DOOR COLUMN

BRACING DETAIL

HYDRAULIC RECESSED MOUNT

2 x 6 Vertical

Need a backer plate to apply

building sheeting to

Vertical stiffeners - 2 x 6's

by each hinge location

Tie back brace

2 x 6 Vertical

X-BRACING

Ceiling

HYDRAULIC

Bottom of Header

SAMPLE OF

DOOR COLUMN

BRACING DETAIL

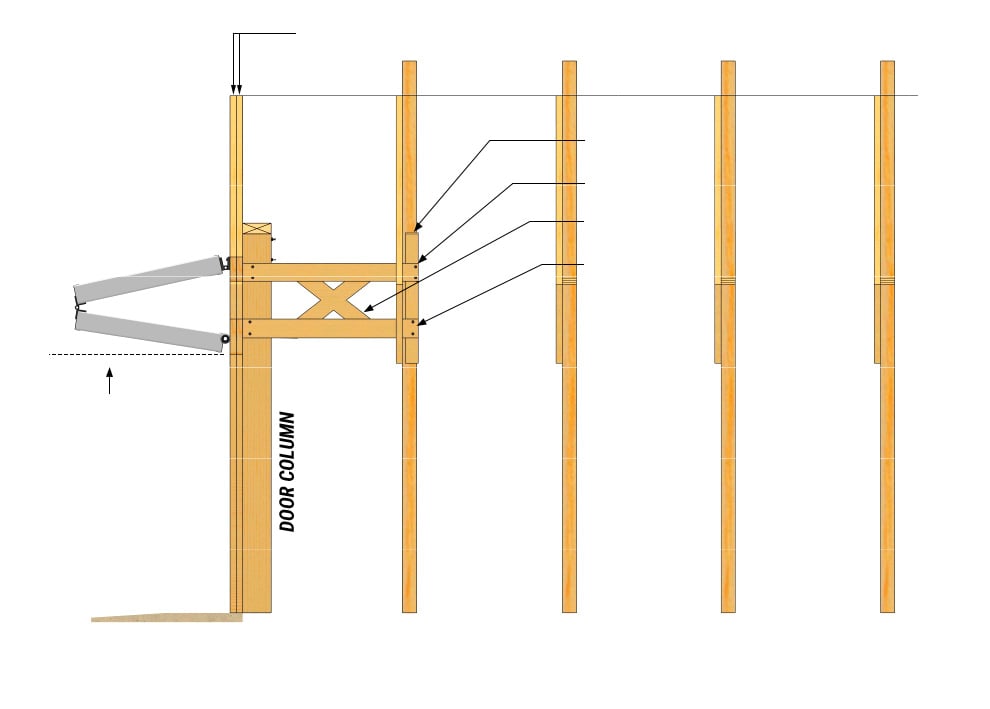

BIFOLD DOOR . . . COLUMN BRACING

(BOTH DOOR COLUMNS - EACH END OF THE DOOR)

BIFOLD

Bottom of

Building Rafter

Double Endwall Rafter

2 x 6 Vertical

Tie Back Brace

X-Brace

Tie Back Brace

BRACE EACH DOOR COLUMN

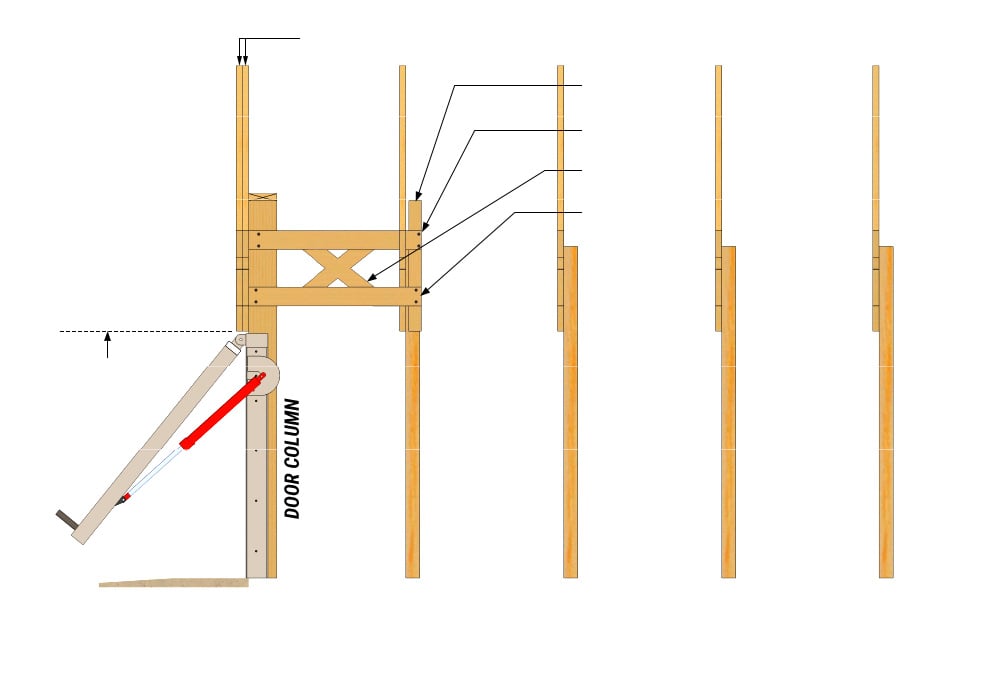

HYDRAULIC DOOR . . . COLUMN BRACING

(BOTH DOOR COLUMNS - EACH END OF THE DOOR)

HYDRAULIC

Bottom of

Building Rafter

Double Endwall Rafter

2 x 6 Vertical

Tie Back Brace

X-Brace

Tie Back Brace

BRACE EACH DOOR COLUMN

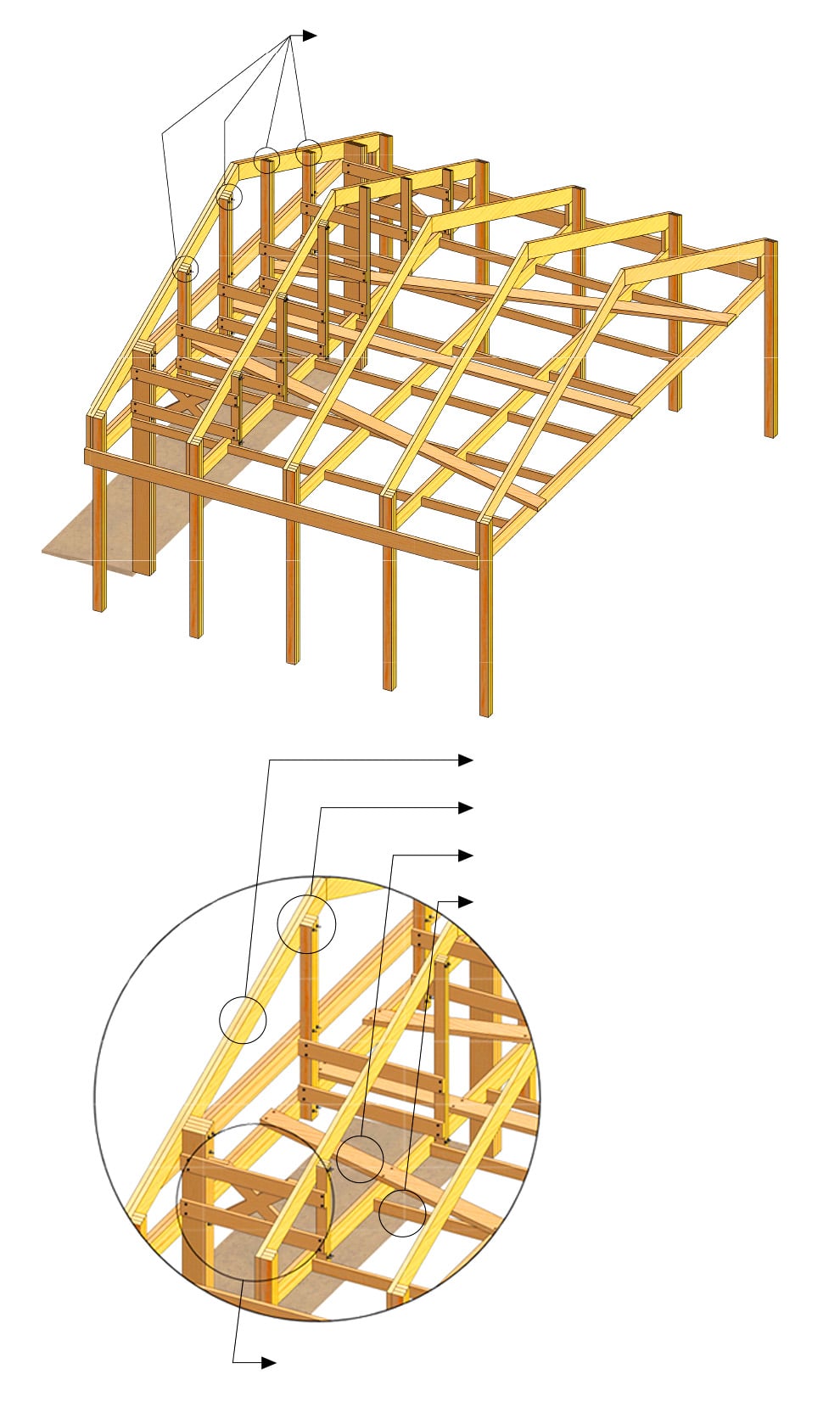

ENDWALL BRACING

- WOOD FRAME

2 x 6 Vertical Stiffener by each hinge location

Double Endwall Rafter

Bolted Connection

2 x 6 tying the rafters together

2 x 4's between rafters

End Door Columns X-Braced back to next rafter

BRACING . . . BETWEEN THE RAFTERS

Door Column

Door Column

X-Bracing

By Each Hinge

2 x 6's Example

Tie the end wall

rafter back with

2 x 6's - Layered

on top of the

building rafters

Straight Back Brace

Lateral Back Brace

Braces between each

building rafter - 2 x 4's or

2 x 6's - Adds extra support

DOUBLE RAFTERS BOLTED TO DOOR COLUMNS

(Style 1)

ON FRONT SIDE OF THE DOOR BUILDING COLUMN

Bolt truss to the building columns

Double Rafter

Deep Door Side Columns

Deep Door Side Columns

Deep Door Side Column

Double Rafter / Endwall Truss

Bolt thru the side columns and double endwall truss

- Bolt Door side columns to the truss

- Building side columns must be full length

DOUBLE RAFTERS BOLTED TO DOOR COLUMNS

(Style 2)

ONE ON EACH SIDE OF THE DOOR BUILDING COLUMN

Note: Use the same "additional support bracing" As (Style 1) on this style of end wall rafter

Additional header plate

(Filler Block)

Bolt hinge thru the

vertical stiffener

Detail:

Bolt through

door header

Vertical stiffeners

(3) 2 x 6's by each hinge location

How to strengthen

your end wall rafters

Bolt rafter to the

door side column

Mount bifold doors

above the clear opening

Side columns must be full length

(On larger doors double the side

columns and go deeper)

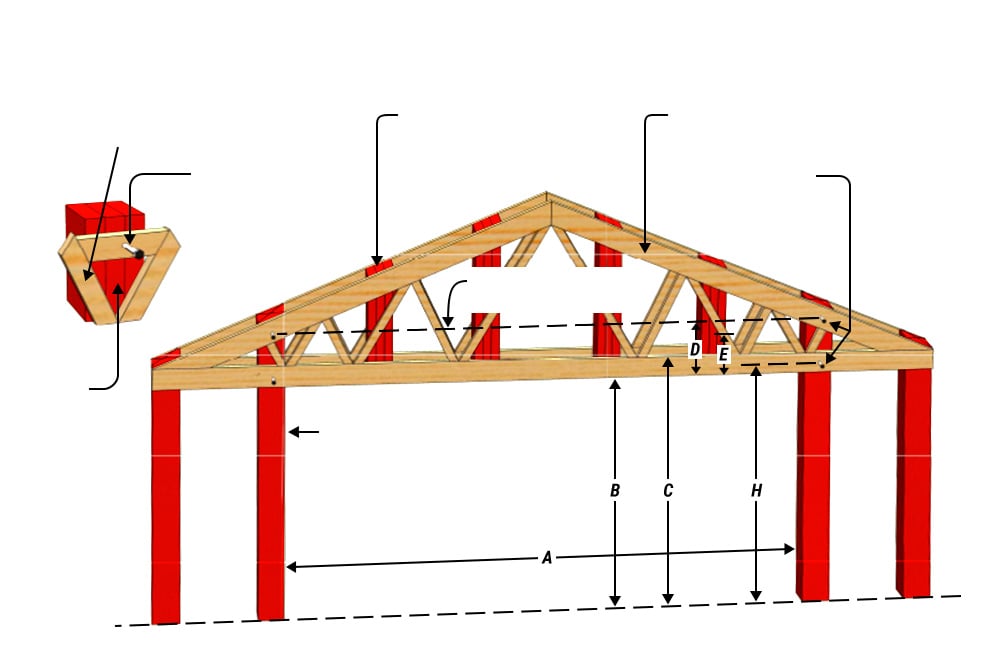

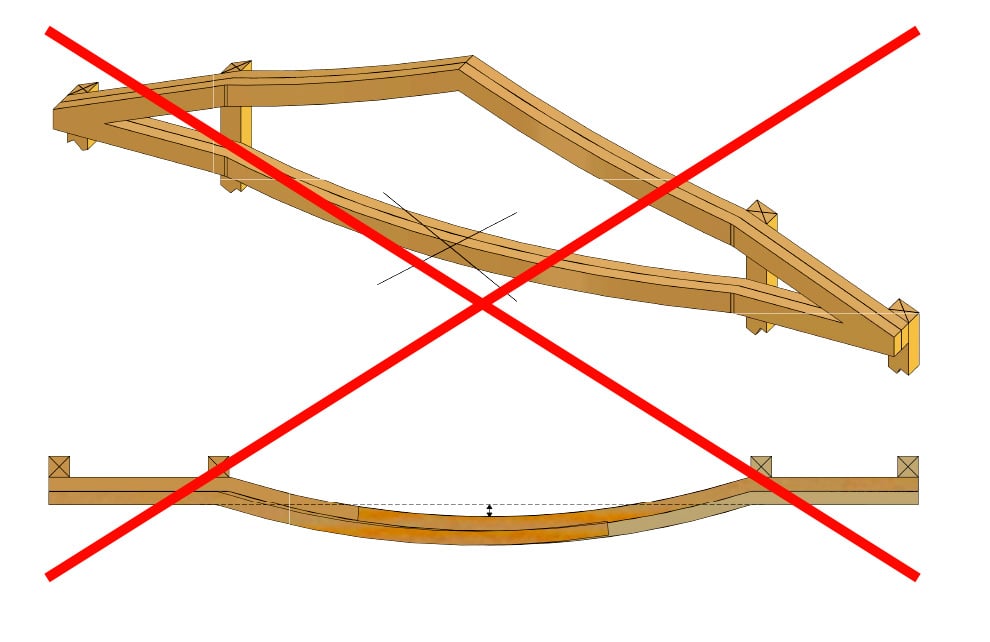

ENDWALL HEADER

- SHOULD BE DOUBLE RAFTERS BACK TO BACK

Straight Rafter - Good

When erecting your building structure - The door header / rafter must be strong.

ENDWALL HEADER/RAFTER

- MUST NOT BOW OUTWARD

Must not bow outward

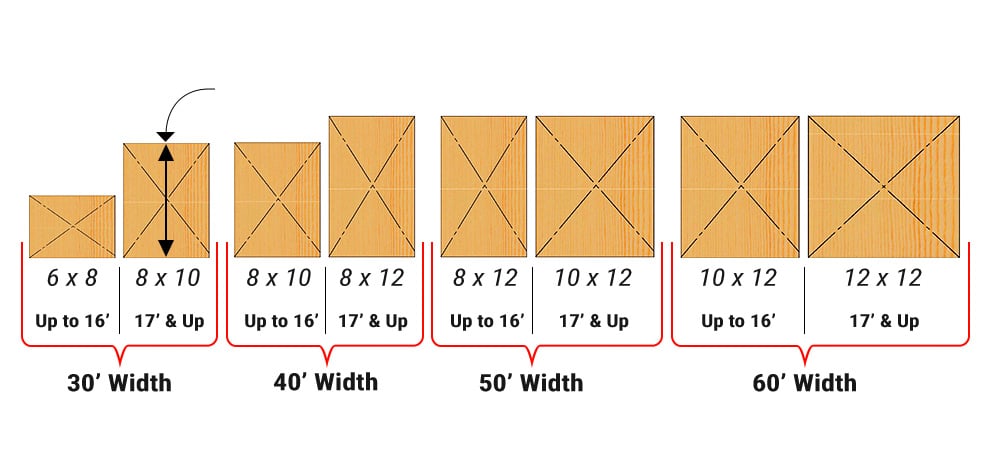

THE DOOR COLUMN SIZE IS VERY IMPORTANT

It is better to have the column be too large rather than too small. If the door column is too small

you will end up putting band-aids on to get the proper strength.

Deeper is Stronger

NOTE - These illustrations are examples only - DO NOT build buildings off of these examples!

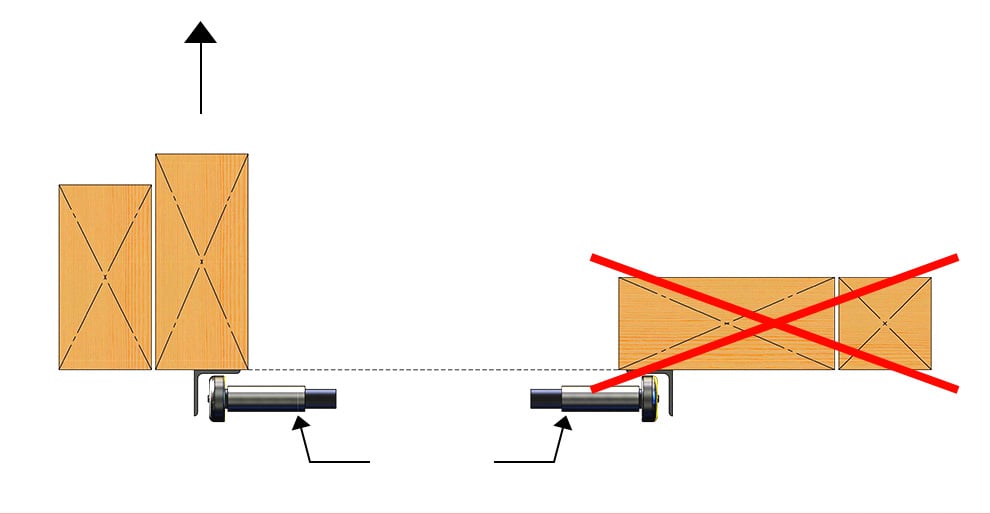

BIFOLD DOOR FORCES . . . ON THE SIDE COLUMNS

Forces

Columns are Stronger

when larger

direction is this way

For more strength position

the columns this way

Bifold Doors

AVOID

placing the columns

this way

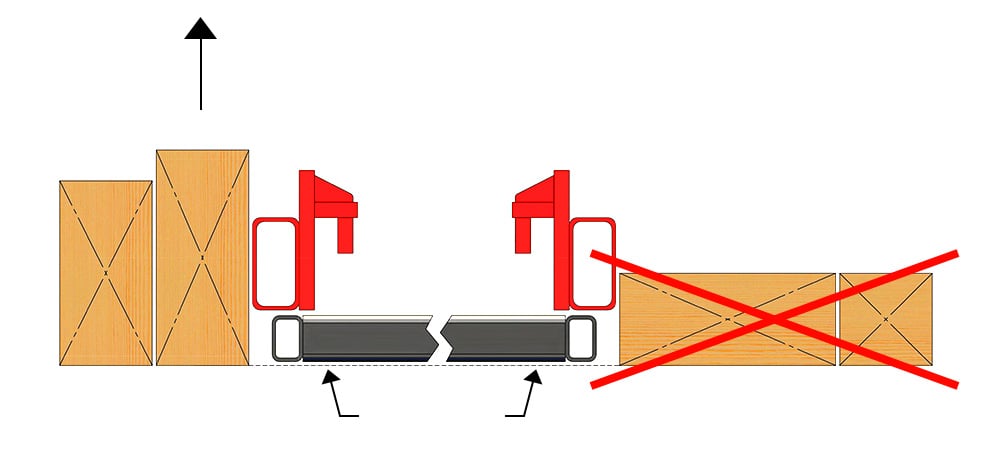

HYDRAULIC DOOR FORCES . . . ON THE SIDE COLUMNS

Forces

Columns are Stronger

when larger

direction is this way

For more strength position

the columns this way

Hydraulic Doors

AVOID

placing the columns

this way

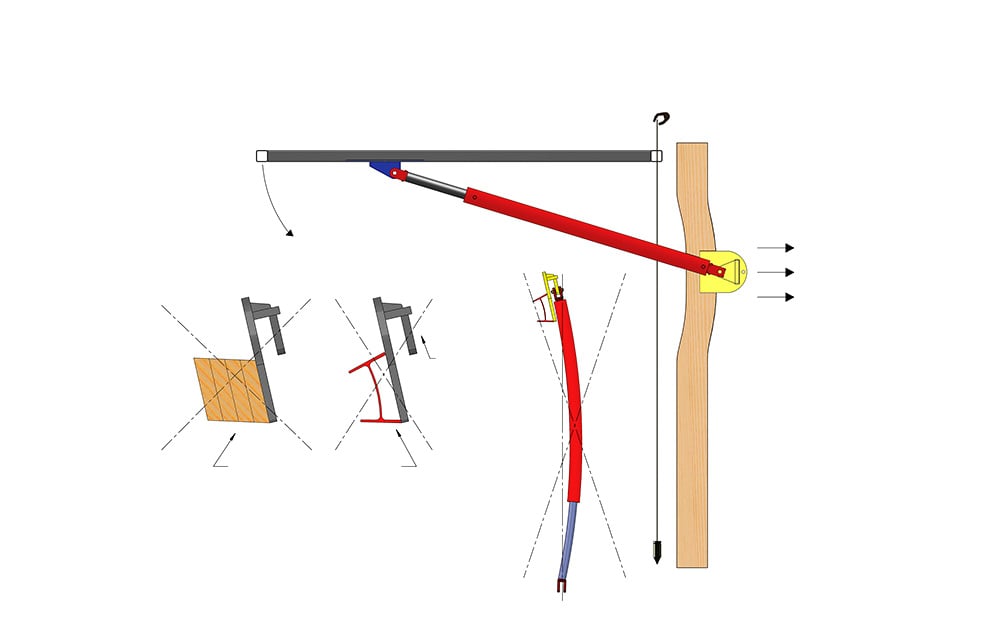

HYDRAULIC DOOR FORCES . . . SIDE VIEW

The hydraulic cylinders exert strong rotating force to the building door side

columns as the door is being operated... See Below

Force on door building column and the Hydraulic Door Subframe

INWARD FORCES

Building columns not braced...Cylinder plate subframe rotating

Cylinder plate moving

Door column not braced - Twisting

Building columns and door subframe MUST NOT

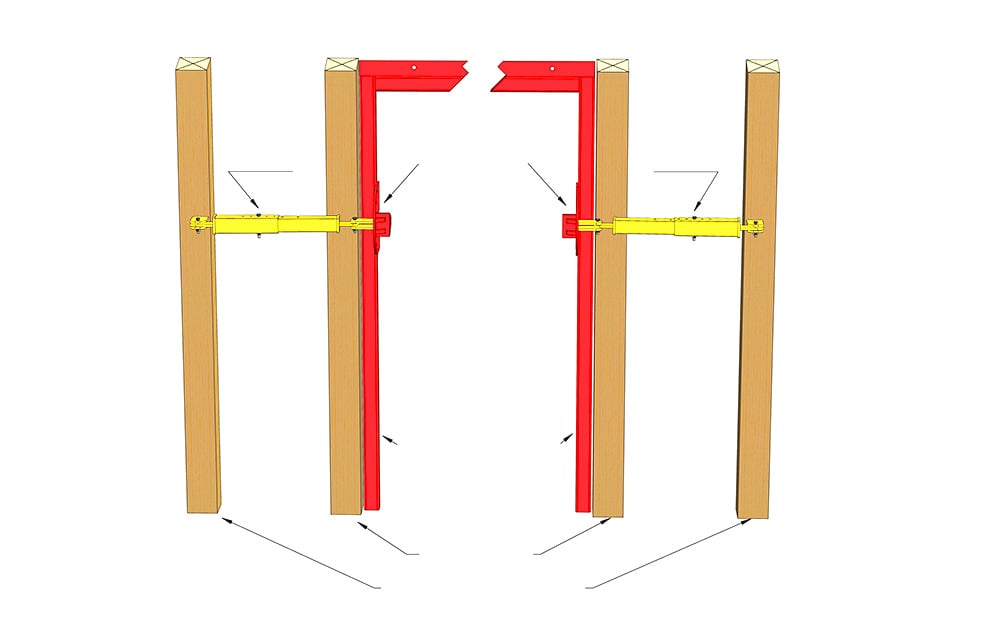

ADDING ADDITIONAL HORIZONTAL BRACING

. . . DOOR COLUMNS

Horizontal Bracing... increase the torsional stiffness of the door column.

The subframe that the hydraulic cylinders attach to mount to the building door side columnss. The hydraulic cylinders exert strong rotating forces to the building door side columns as the door is being operated. It is important to limit the rotation of the door side columns. To aid in limiting this rotation, horizonatal braces are strongly recommended at the point on the door column where the cylinder attaches.

Hyd. Door Subframe Header Tube

Added

Horizontal

Bracing

Cylinder Plate

Added

Horizontal

Bracing

Hyd. Door Subframe

Door left off

Door Columns

Adjacent Building Columns

Horizontal bracing is used to stop the doors vertical subframe and cylinder bracket and buildings door side column from twisting. To help resist the torsional forces in the door side column, use horizontal bracing to the next adjacent building column in the plane of the door. These horizonal braces help resist the torsional load in the door side column.

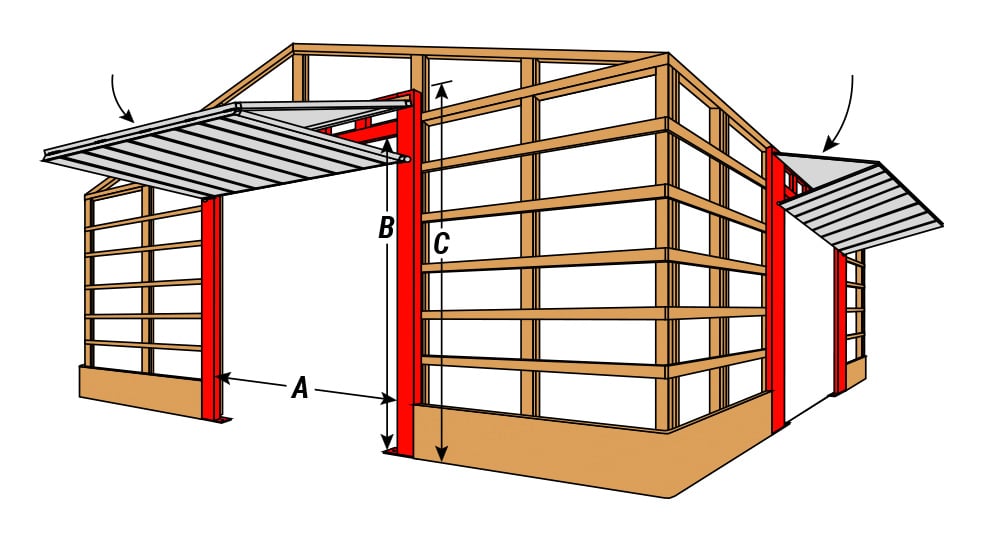

FREE STANDING HEADER . . . ADDS ADDITIONAL STRENGTH

Freestanding Header

FREE STANDING HEADER . . . END WALL AND SIDE WALL

ENDWALL

SIDEWALL

FREE STANDING HEADERS . . . ARE CUSTOM BUILT

ENDWALL

SIDEWALL

FREE STANDING HEADER . . . MOUNTED ON SIDE WALL

LATERAL BRACING

EXTENSION HEADER BRACKET

(Sized per door / place by each hinge)

SIDEWALL

Wood Building

Side Column

FREESTANDING HEADER

SIDE VIEW

Building Sheeting

Extension Header

Bracket

Single Hinge

FREESTANDING HEADER

Doorframe

Lateral Bracing

Double 2 x 12

Wood Building

Side Column

UNDERSTAND LARGE MOVING DOORS . . .

Hydraulic or Bifold Doors

UNDERSTANDING LARGE MOVING DOORS... HYDRAULIC OR BIFOLD DOORS

Quote... A farmer asked...

When the door is hanging straight out there, you better have something strong holding those cylinders. Doesn't the door put a lot of stress on the building?

That goes for both style of doors.

Quote... A engineer once said...

The doors WILL find the weak points in our building design. Many wood building engineers have a tendency to get lax with the design of the door supports and framing surrounding your doors and forget that we not only have to support the weight and wind on the door, we also have to support its operation.

*NOTE: "IT'S BETTER TO OVERBUILD YOUR BUILDING THAN TO MAKE COSTLY REPAIRS LATER"

MYTHS THAT CAN'T BE IGNORED

MYTH:

- Building does not have to be made stronger.

- Building does not have to be modified to hold a hydraulic / bifold door.

- Building does not have to be engineered with extra reinforcing to accept a Hydraulic/Bifold Door.

- Door does not hang on your building . . . What does the door and frame attach to?

COMMON MYTH:

- The door is self-supporting and does not add any load to your building.

ASK YOURSELF:

Is the door like a billboard? Could the door be erected in your parking lot ? The door could not possibly be erected independent of your building. The only way that the door would not add load to your building is if they were selling you a billboard that would lift itself without falling over. Otherwise, all of the forces and loads from the door opening and from windloads gets transferred through the door sub-framing to your building.

RED FLAG:

- When anyone tells you that the door does not put load your building, that should be a red flag to tell you that they don't understand large moving doors.

- Door can be left open in windy conditions, BUT can the buildings withstand the forces...

USE COMMON SENSE when designing your building to accept a Hydraulic / Bifold Door

And refer to the SCHWEISS DOOR SPECIFICATION SHEETS and Reactions sheet to help understand the forces.

Schweiss Specs are supplied with each door.

HYDRAULIC DOOR FORCES

HORIZONTAL DOOR COLUMN BRACING.... INCREASE THE TORSIONAL STIFFNESS OF THE DOOR COLUMN

- Hydraulic doors come with two powerful cylinders that are pre-mounted to a vertical subframe, one cylinder on each side of the door opening.

- The subframe that the hydraulic cylinders attach to must be fastened to the buildings door side columns.

- The hydraulic cylinders exert strong rotating forces to the buildings door side columns as the door is being operated.

- It is important to limit the rotation of the door side columns as the door is opening and closing, also when in the open position.

HELPFUL

- To aid in limiting this rotation, horizontal braces are strongly recommended at the point on the door column where the cylinder attaches.

- Horizontal bracing is used to stop the doors vertical subframe, cylinder bracket and buildings door side column from twisting.

- The door cylinders and cylinder plate attach to vertical subframe members which are all connected to the buildings door side column on each side of the door opening.

- To help resist the torsional forces in the door side column, use horizontal bracing to the next adjacent building column in the plane of the door.

- These horizontal braces help resist the torsional load in the door side column.

PREPARING YOUR BUILDING

- HYDRAULIC / BIFOLD DOOR

THINGS TO CONSIDER WHEN PREPARING YOUR BUILDING FOR A HYDRAULIC/BIFOLD DOOR

#1. . . . . Is bracing necessary and what should the bracing look like?

#2. . . . . Poorly designed buildings and buildings that are designed properly.

#3. . . . . Old and new buildings.

FIRST:

The strength of columns and beams is a function of the material (steel or wood) and its size (2x6 is stronger than 2x4 because it has more material) and how it is braced (stability). Even very large (seemingly strong) columns do not have much capacity if they are not braced.

The larger the column size, the less bracing it usually needs. It is possible to design columns as (unbraced) but the size of the column tends to become very large and would likely be aesthetically unacceptable.

If we are going to brace columns, what does the brace need to look like? Braces on columns need to brace each axis of the column. You typically need less bracing on one axis of the column than the other. You also need to make sure that the bracing is effective. Effective bracing keeps the column from buckling (like when you put a straw between your fingers to see it bend), it also has to keep it from rotating. Rotation can be caused by axial load, when the entire column is loaded, if the outside face of the column is braced, but the inside face or flange is not. For columns that have an unbraced inside face or flange, additional bracing is usually required. Metal building people typically use flange braces, but the bracing may be horizontal to a second column that is near the column you want to brace (lean-on bracing).

SECOND:

This leads to the second topic of building design.

The building could be considered to be "acceptably designed" if the designer is told the correct loads that are going to be put on the building (dead load, torsion, eccentric loading, etc.) and they have designed the building to resist all of those loads. A "better design" would consider the desires of the customer. For example, if the customer were going to have an interior finish, you want the braces designed so that they did not extend beyond the inside face of the column.

THIRD:

The question of existing buildings:

Existing buildings can be a bigger problem. They were probably not designed for whatever you want to do or add to your building. The original designer or building company may not be willing to help. It is important to either have a qualified engineer or the original designer or building company design the modification using the correct loads and eccentricity information. All of the "recommendations" that Schweiss has on their spec sheets are good basic common sense recommendations that go a long way toward making the building right. The final responsibility lies with the building owner of an existing building. If they get a qualified engineer or the original engineer or building company to help them, then they can take that responsibility. The qualified engineer or original engineer or building company can look at Schweiss' recommendations and decide what is really required.

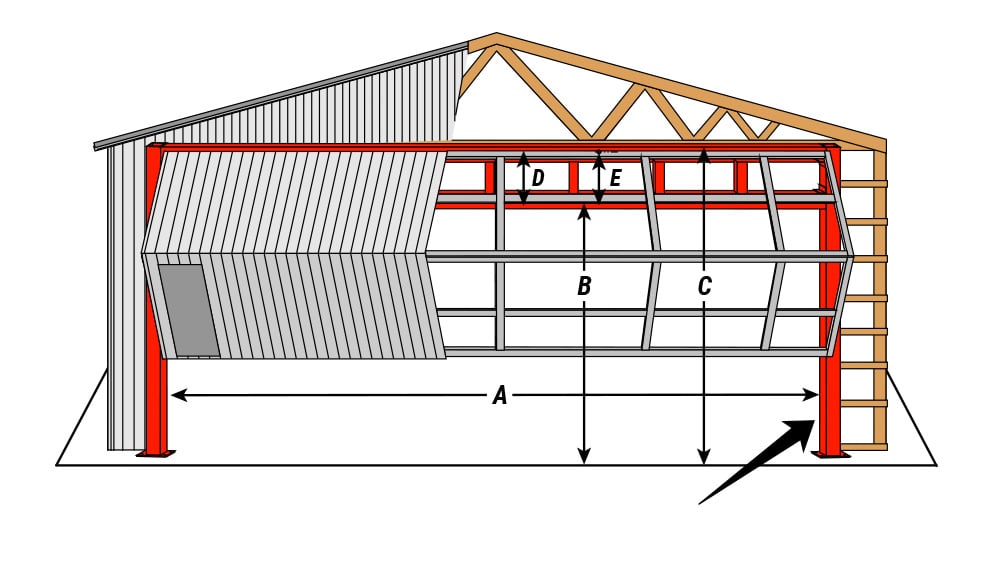

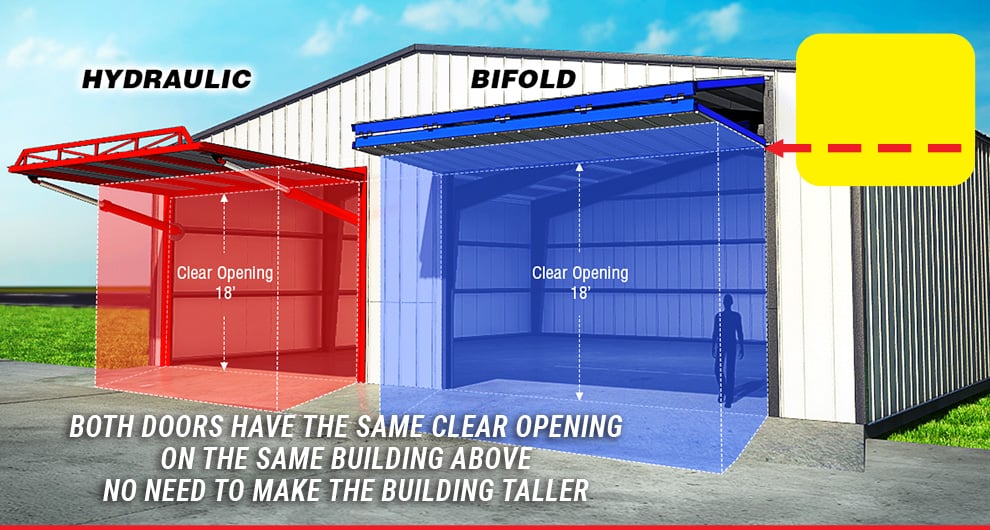

THERE IS NO NEED TO MAKE THE BUILDING TALLER . . .

Where you hang the door makes all the difference.

Schweiss makes both styles of doors so... THE CHOICE IS YOURS!

LOSE NO HEADROOM

BIFOLD DOORS

ATTACH ABOVE

THE CLEAR OPENING

(NOT UNDER THE HEADER)

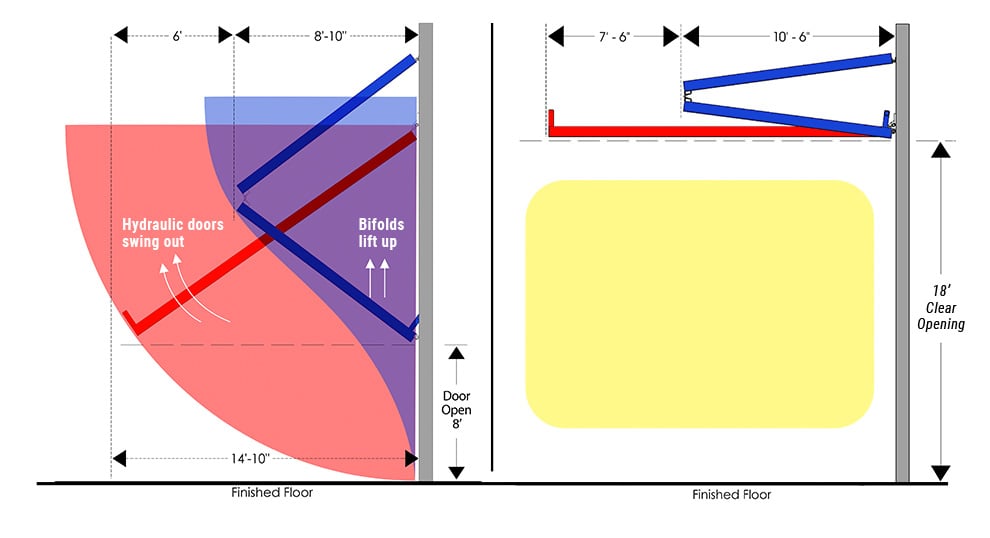

DOOR TRAVEL COMPARISON

PARKING COMPARISON

- Hydralic doors ( red arc) swing out when opening ................... Requires a stay back area.

- Bifold doors ( blue arc ) lift up when opening ........................... Parking not an issue.

OPEN POSITION COMPARISON

BI-FOLD DOORS

Fold in half when open putting less stress

on the building and create a slight slope

allowing water to run off.

HYDRAULIC DOORS

Protrude straight out off the building at 90

degrees and lays flat when fully open

SCHWEISS MANUFACTURES BOTH STYLES OF DOORS

WHAT DOOR DO YOU PREFER

PARKING COMPARISON

- SEE THE DIFFERENCE

"One-Piece"

HYDRAULIC DOORS

Provides Extra Shade

Lose No Headroom

Lift-Strap

BIFOLD DOORS

Saves Parking Space Outside